Atmospheric pressure production process for beta-(3.5-diteritiary butyl-4-hydroxy phenyl)propionic acid octadecanol ester

A technology of stearyl propionate and hydroxyphenyl, which is applied in the field of normal pressure production process of beta-(3.5-di-tert-butyl-4-hydroxyphenyl) stearyl propionate, can solve the problem of investment increase , Difficulty in methanol recovery, environmental pollution in emission treatment, etc., to achieve the effect of reducing production costs, equipment standards and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

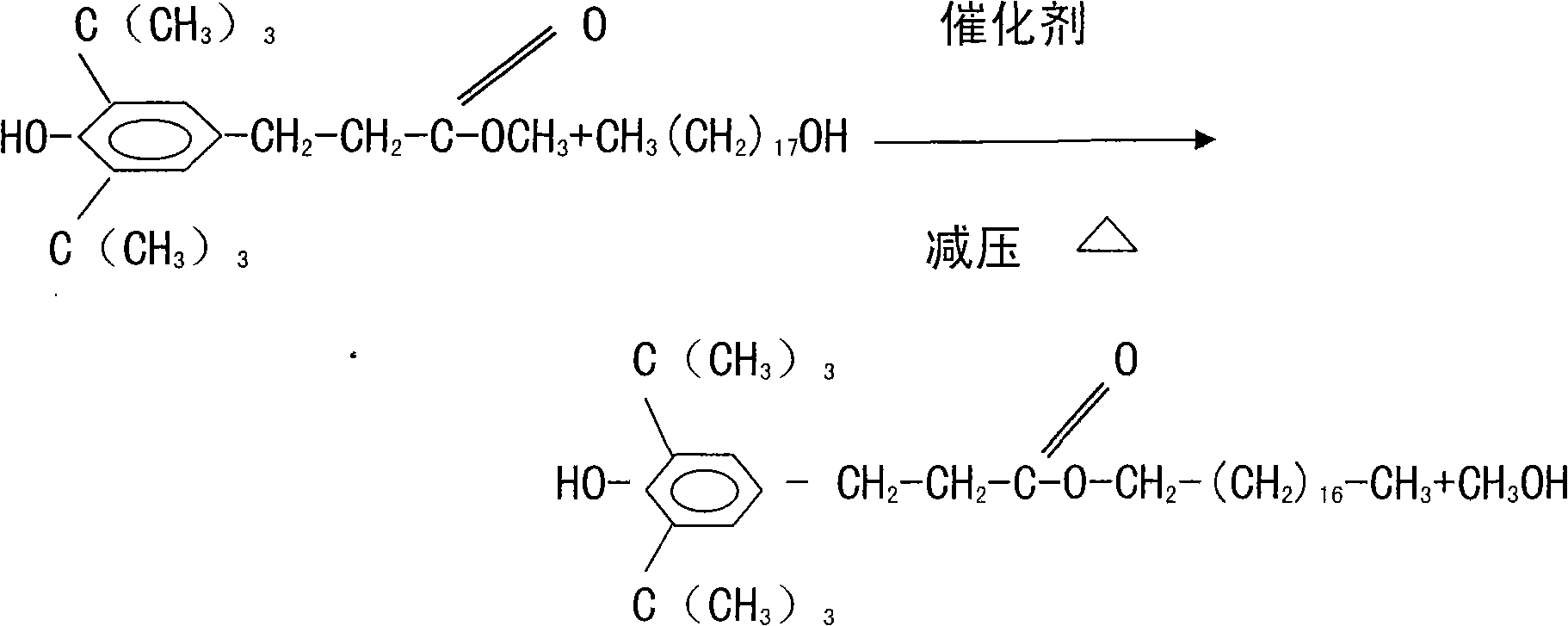

[0012] Put 200g of A, 180g of stearyl alcohol, and 2.5g of dibutyltin oxide into the reactor in turn, and pass through the N 2 , heat up, start the stirring device after the material is dissolved, react at a temperature of 160-200° C. for 6-12 hours, and the reaction ends. After dissolution, decolorization, hot filtration, crystallization, and drying, 337 g of the finished product β-(3.5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate was obtained, with a yield of 95%; 16 g of methanol was recovered, with a yield of 75% %. Reaction equation of the present invention:

[0013]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com