High-temperature acidification corrosion inhibitor and preparation method thereof

A technology of acidification corrosion inhibitor and high temperature, which is applied in the field of high temperature acidification corrosion inhibitor and its preparation, can solve the problems of insignificant corrosion inhibition effect, single application range, poor temperature resistance, etc., and achieve good corrosion inhibition effect and compatibility, Good water solubility and strong temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

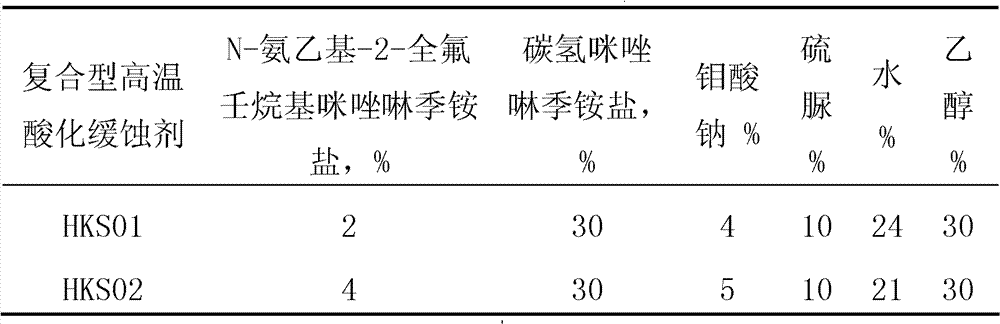

[0020] Prepare the high-temperature acidification corrosion inhibitor according to the weight of each component in Table 1, add the raw materials in Table 1 to the reaction kettle in turn, and stir at 60°C for 20-30 minutes to prepare two acidification corrosion inhibitors HKS01 and HKS02, as shown in Table 1. Show.

[0021] Table 1 Composition of different high temperature acidizing corrosion inhibitors

[0022]

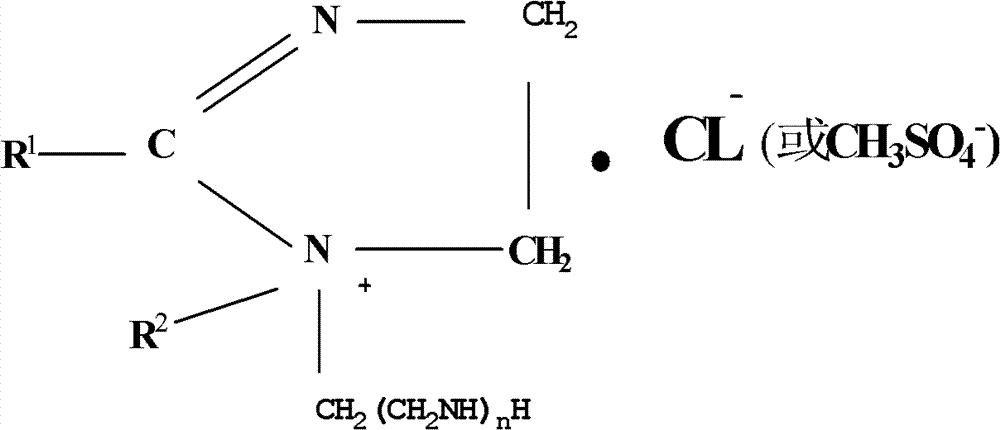

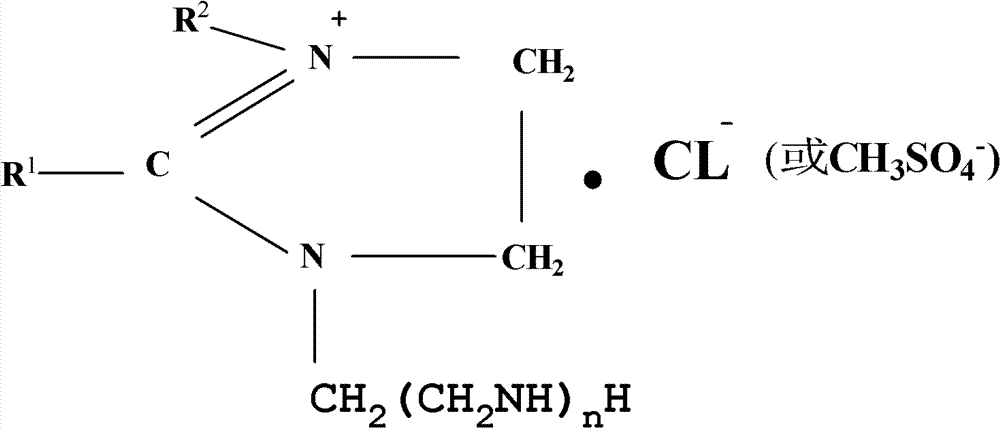

[0023] The N-ethylamino-2-perfluorononylimidazoline quaternary ammonium salt adopted in the present embodiment adopts structural formula (1), shown in (2), wherein R 1 for CF 3 -(CF 2 ) 8 , R 2 For ethyl. The hydrocarbon imidazoline quaternary ammonium salt used in this embodiment is 1-benzyl 1-aminoethyl-2-heptylalkylimidazoline quaternary ammonium salt.

Embodiment 2

[0024] Example 2: Toxicity test of N-ethylamino-2-perfluorononylimidazoline quaternary ammonium salt, the main agent of high-temperature acidification corrosion inhibitor

[0025] Take a sample of N-ethylamino-2-perfluorononyl imidazoline quaternary ammonium salt and send it to Shaanxi Food and Drug Inspection Institute LD 50 In the test, the result showed 1046.41mg / kg, indicating that the product is of low toxicity level.

Embodiment 3

[0026] Embodiment 3: corrosion inhibitor evaluation example:

[0027] Evaluation of fluorine-containing imidazoline quaternary ammonium hydrochloride corrosion inhibitor: chemically pure acid solution is used, prepared with deionized water, the concentration measurement is carried out according to GB622-89, and the dosage of corrosion inhibitor is uniformly calculated and added according to weight percentage. Add a corrosion inhibitor (according to the amount of hydrochloric acid) into the uniformly configured 15% hydrochloric acid solution, mix well, heat to 90°C, and then add it to the high-pressure reactor. Tie the treated N80 steel test piece to the hanging hole of the PTFE disc of the kettle cover with a PTFE tape, and cover the kettle cover. When the temperature rises to 138°C, adjust the rotating speed to 100r / min, start recording the time and pressure, keep it at 140°C for 4 hours, and then cool it quickly with cooling water. When the temperature was lowered to 90°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com