Electrolyte for chip aluminum electrolytic capacitor and preparation method thereof

A technology of aluminum electrolytic capacitors and electrolytes, applied in the field of electrochemistry, to achieve the effects of eliminating pressure rise, not easy to crystallize, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing an electrolyte for a chip type aluminum electrolytic capacitor, comprising the following steps:

[0035] (1) Weighing: Weigh the raw materials according to the following formula;

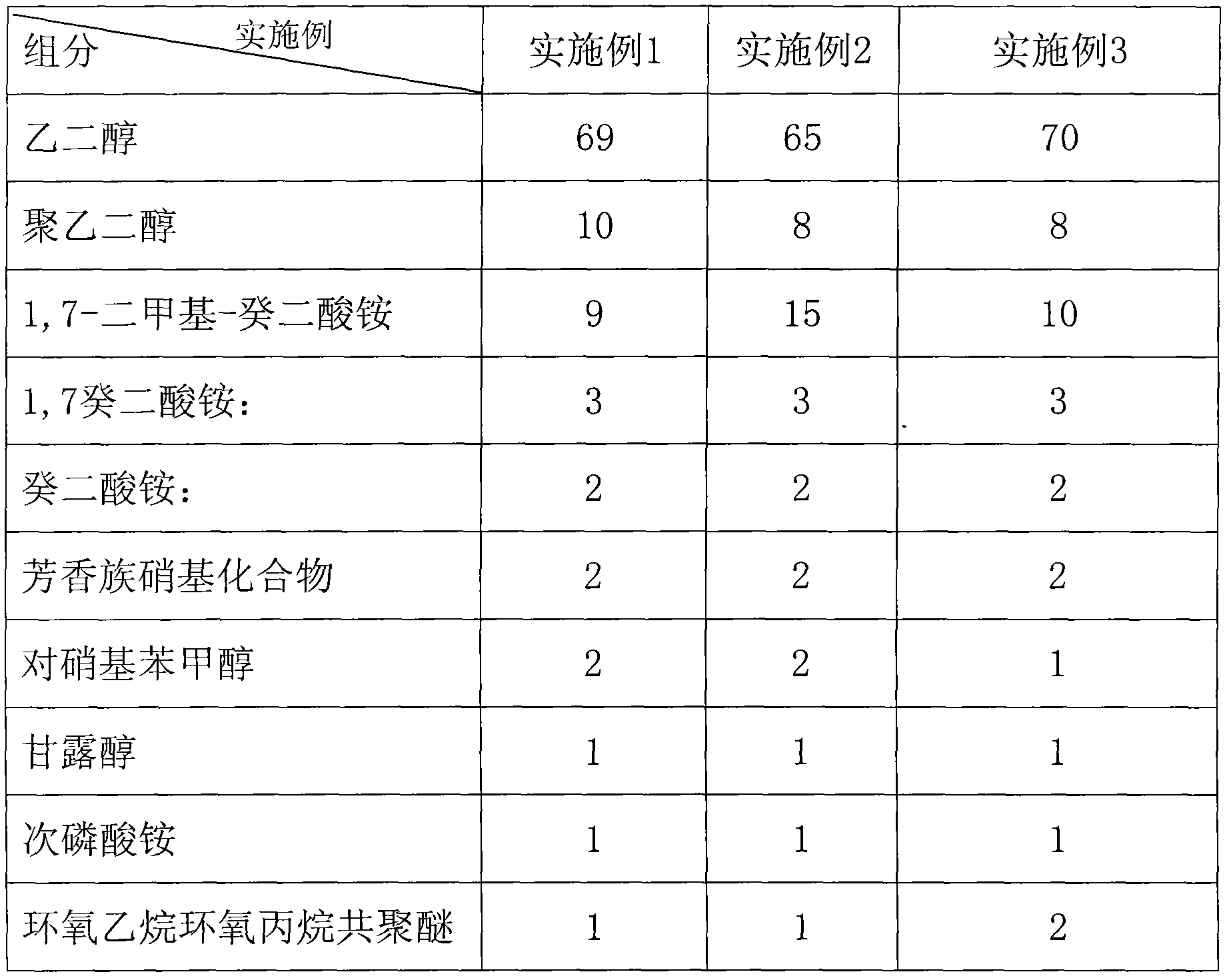

[0036] Table 1

[0037] Component Weight (g)

[0038]

[0039] Ethylene glycol 69

[0040] Polyethylene glycol 10

[0041] 1,7-Dimethyl-ammonium sebacate 9

[0042] 1,7 ammonium sebacate: 3

[0043] Ammonium sebacate: 2

[0044] Aromatic nitro compounds 2

[0045] p-Nitrobenzyl alcohol 2

[0046] Mannitol 1

[0047] Ammonium hypophosphite 1

[0048] Ethylene oxide propylene oxide copolyether 1

[0049] (2) Dissolution: Add ethylene glycol into a container with a stirrer and a thermometer, raise the temperature to 60°C with a closed electric heater, add polyethylene glycol, 1,7 ammonium sebacate, and ammonium sebacate in sequence , 1,7-dimethyl-ammonium sebacate, mannitol, ammonium hypophosphite, p-nitrobenzoic...

Embodiment 2

[0051] Embodiment 2, implementation 3 are basically the same as embodiment 1, the difference is that the composition of raw materials is different, see Table 2.

[0052] Table 2

[0053]

[0054] Five chip-type aluminum electrolytic capacitors of 400V, 450V, and 470V were prepared from the electrolytes of the above examples, and the performance of the capacitors was tested. The result: all of them can withstand 125°C and more than 2000 hours of load carrying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com