Preparation method and application of ionic liquid modified carbon sphere loaded platinum nanoparticle catalyst

A technology of ionic liquid and platinum nanometer, which is applied in the direction of catalyst activation/preparation, catalyst carrier, physical/chemical process catalyst, etc., can solve the problems of few researches on nanoparticles, and achieve the goal of optimizing performance, increasing specific surface area, and improving electrical conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

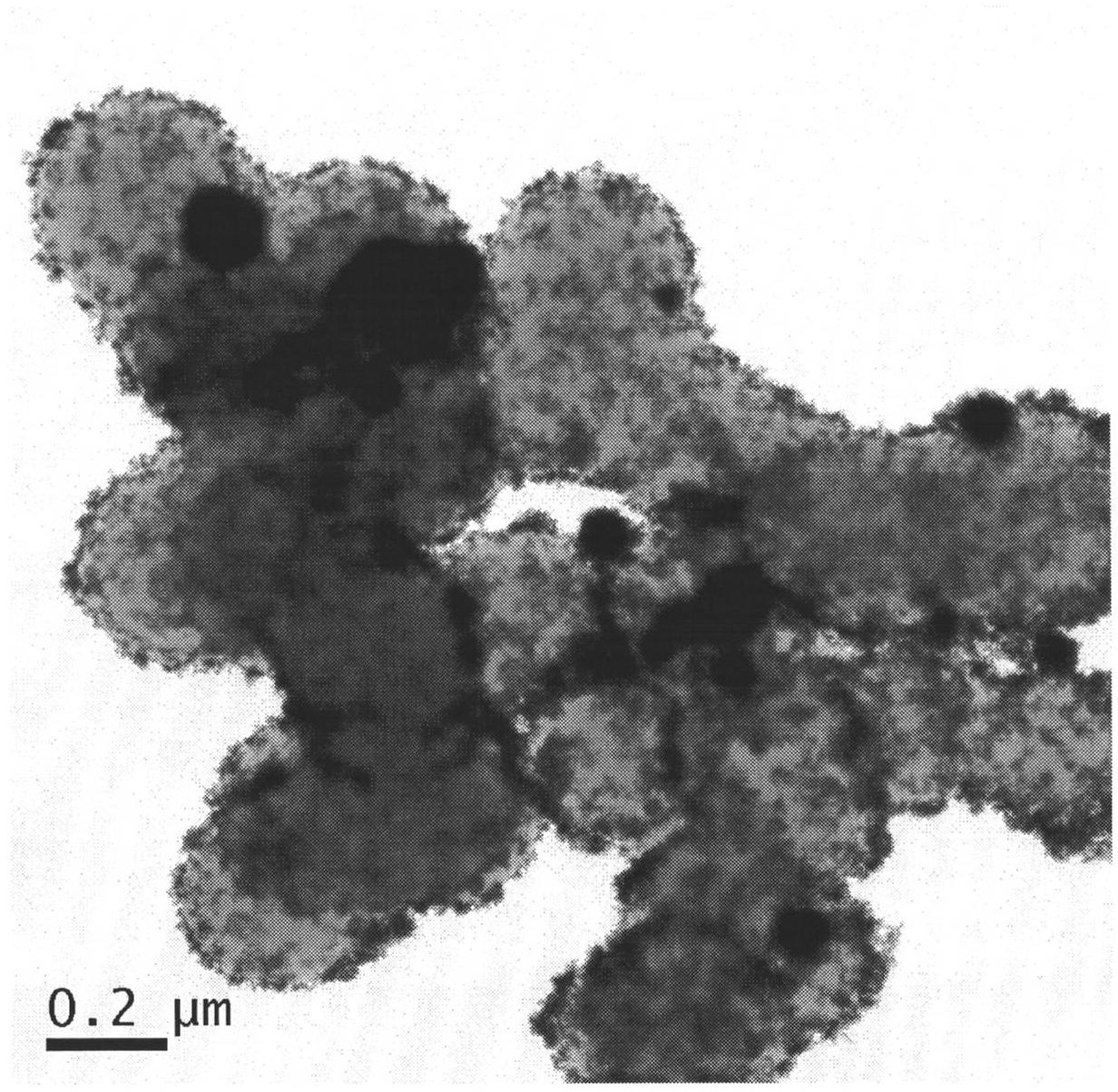

[0041] Embodiment 1: Preparation of carbon sphere supported platinum nanoparticle catalyst

[0042] A preparation method of carbon sphere supported platinum nanoparticle catalyst, comprising the following steps:

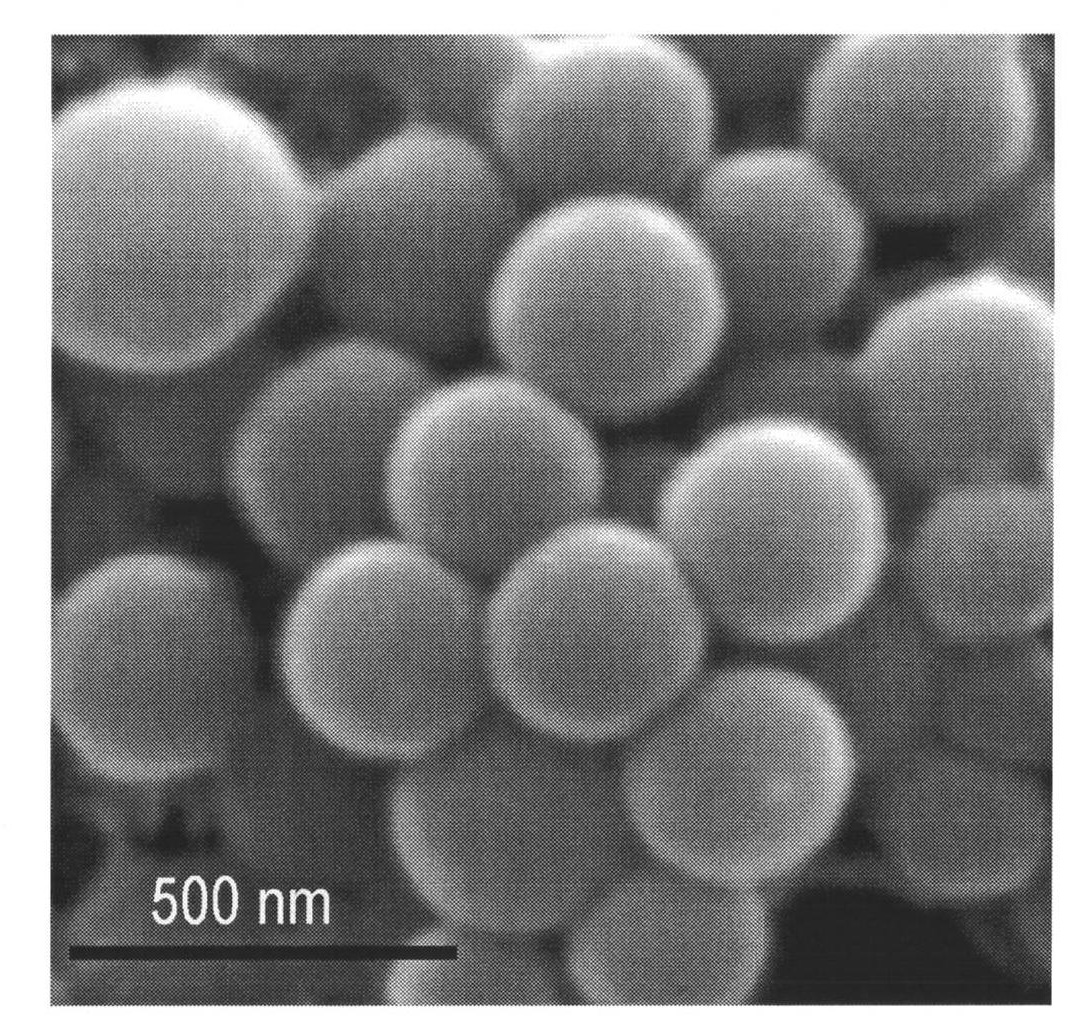

[0043] (1) Preparation of carbon spheres

[0044] Fully dissolve 5g of glucose into 100ml of deionized water, put it into a stainless steel hydrothermal kettle lined with polytetrafluoroethylene, and react in a vacuum oven at 160°C for 4 to 6 hours to obtain a brown solution. Centrifuge at a speed of 20 minutes, and dry the separated precipitate in a vacuum oven at 60°C. figure 1 Scanning electron microscope (SEM) photos of carbon spheres with a diameter of about 500 nm are prepared.

[0045](2) Synthesis of imidazolium salt ionic liquid

[0046] The ionic liquid of imidazolium salt type is synthesized as follows: its synthetic method reference (Y.J.Zhang, Y.F.Shen, J.H.Yuan, D.X.Han, Z.J.Wang, Q.X.Zhang, L.Niu, Angew.Chem.Int.Ed.2006,45,5867) Add 2.2g of 3-bromo...

Embodiment 2

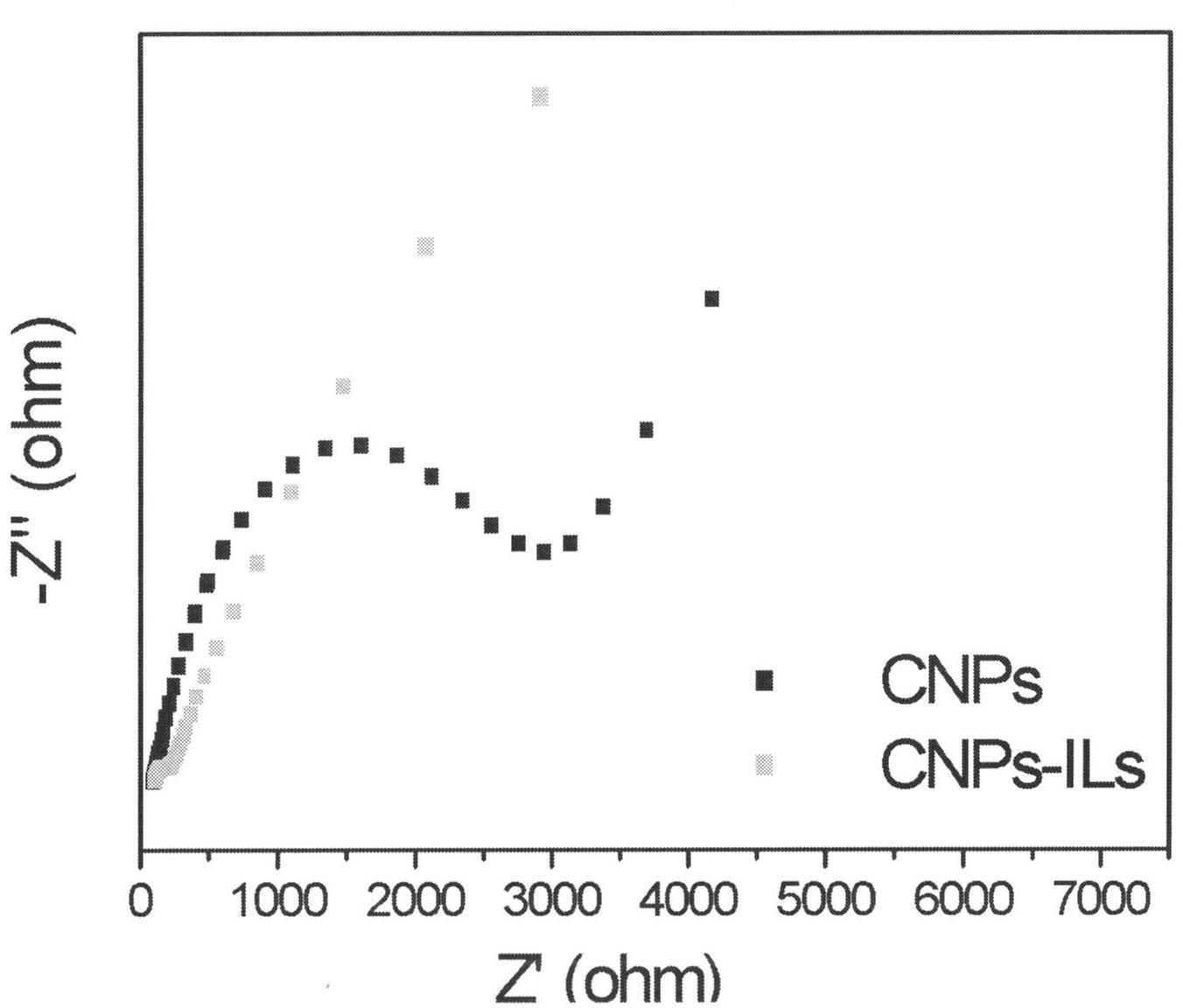

[0055] Example 2: Application of Ionic Liquid Modified Carbon Spheres Supporting Platinum Nanoparticle Catalysts

[0056] The glassy carbon electrode was modified with the ionic liquid modified carbon spheres supported platinum nanoparticles catalyst obtained in Example 1 above, and a three-electrode system was selected to perform electrocatalysis on methanol. The specific operation steps are as follows: the glassy carbon electrode (3 mm in diameter) is ground into a mirror surface with alumina grinding fluid, then cleaned with ethanol and acetone, and dried under nitrogen atmosphere. Then add 1 mg of the ionic liquid-modified carbon sphere-loaded platinum catalyst obtained in Example 1 into 1 ml of secondary water, disperse it ultrasonically, spread 5 microliters on the surface of the glassy carbon electrode, and wait for it to dry naturally or place it under an infrared lamp. Lower to bake. Then add 10ml of 30mmol / L Nafion ethanol solution dropwise, and dry it naturally or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com