Preparation method of non-integer ratio graphene selenium cobalt nano sheet

A cobalt selenide nanometer and non-integer ratio technology, which is applied in nanotechnology, binary selenium/tellurium compounds, chemical industry, etc., can solve the problems of cobalt selenide synthesis and less application, and achieve small product particles, thin thickness, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of cobalt selenide nanosheets under different conditions:

[0024] This step is the stage of exploring conditions for preparing the product cobalt selenide nanosheets. (1) Add 0.1455 grams of cobalt nitrate hexahydrate and 0.0866 grams of sodium selenite to 25 milliliters of autoclaves with Teflon linings, then add 20 milliliters of ethylene glycol, stir for 20 minutes, and seal the reaction The kettle was put into a digital display temperature-controlled furnace, and reacted at 140, 160, 180, and 200 degrees Celsius for 24 hours. (2) Add 0.1455 grams of cobalt nitrate hexahydrate and 0.0866 grams of sodium selenite to 25 milliliters of autoclaves with Teflon linings, then add 20 milliliters of ethylene glycol, stir for 20 minutes, and seal the reaction The kettle was put into a digital display temperature-controlled furnace, and reacted at 180 degrees Celsius for 12, 24, and 48 hours respectively. (3) Add 0.1268 gram of cobalt nitrate hexahy...

Embodiment 2

[0030] Embodiment 2: Preparation of cobalt selenide nanosheets:

[0031] Add 0.1455 grams of cobalt nitrate hexahydrate and 0.0866 grams of sodium selenite to 25 milliliters of autoclaves with polytetrafluoroethylene linings, then add 20 milliliters of ethylene glycol, stir for 20 minutes, seal the reaction vessel, and put Put it into a digital display temperature-controlled furnace, and react at 180 degrees Celsius for 24 hours. The obtained product was washed with distilled water and ethanol several times and then dried for characterization and testing.

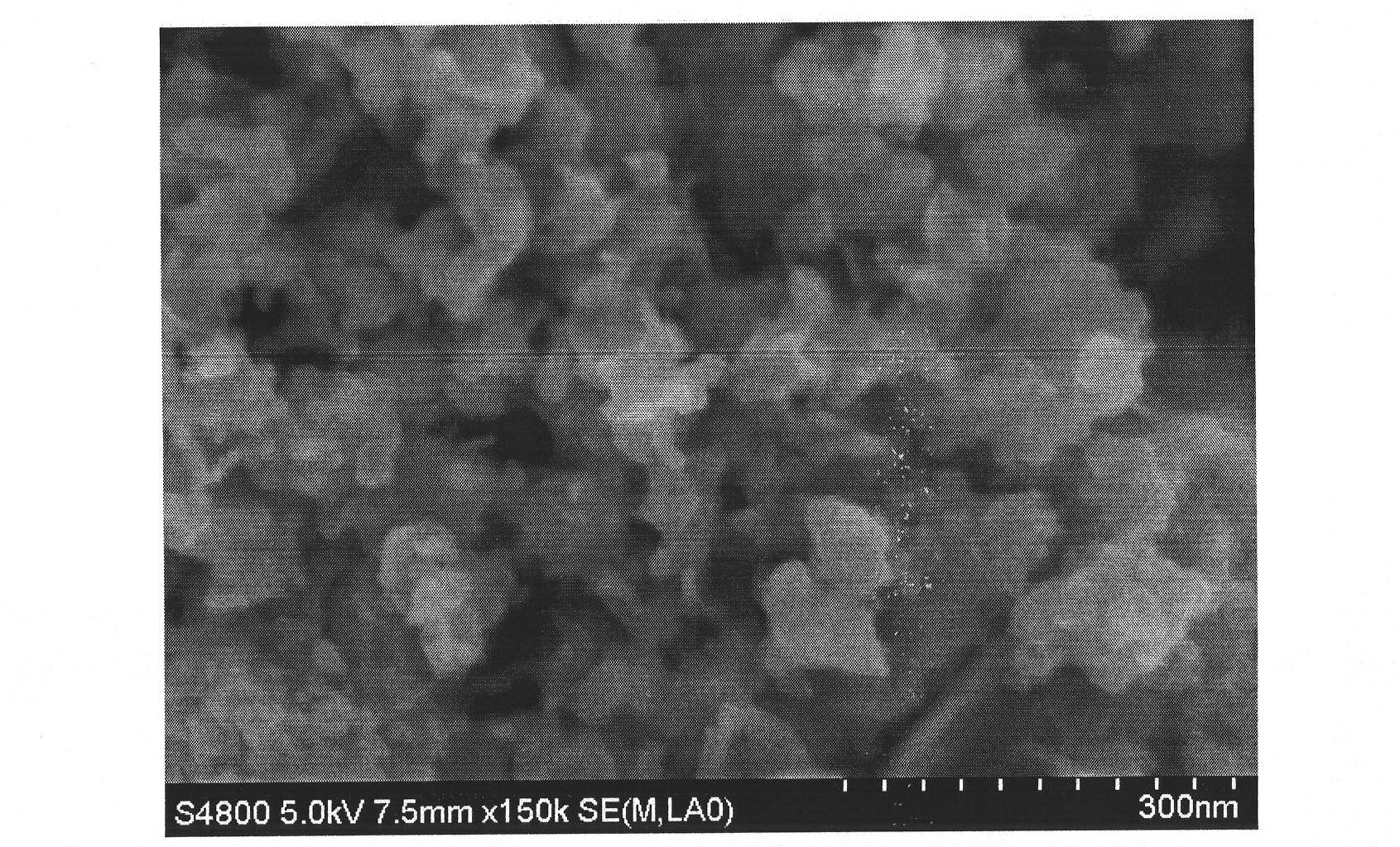

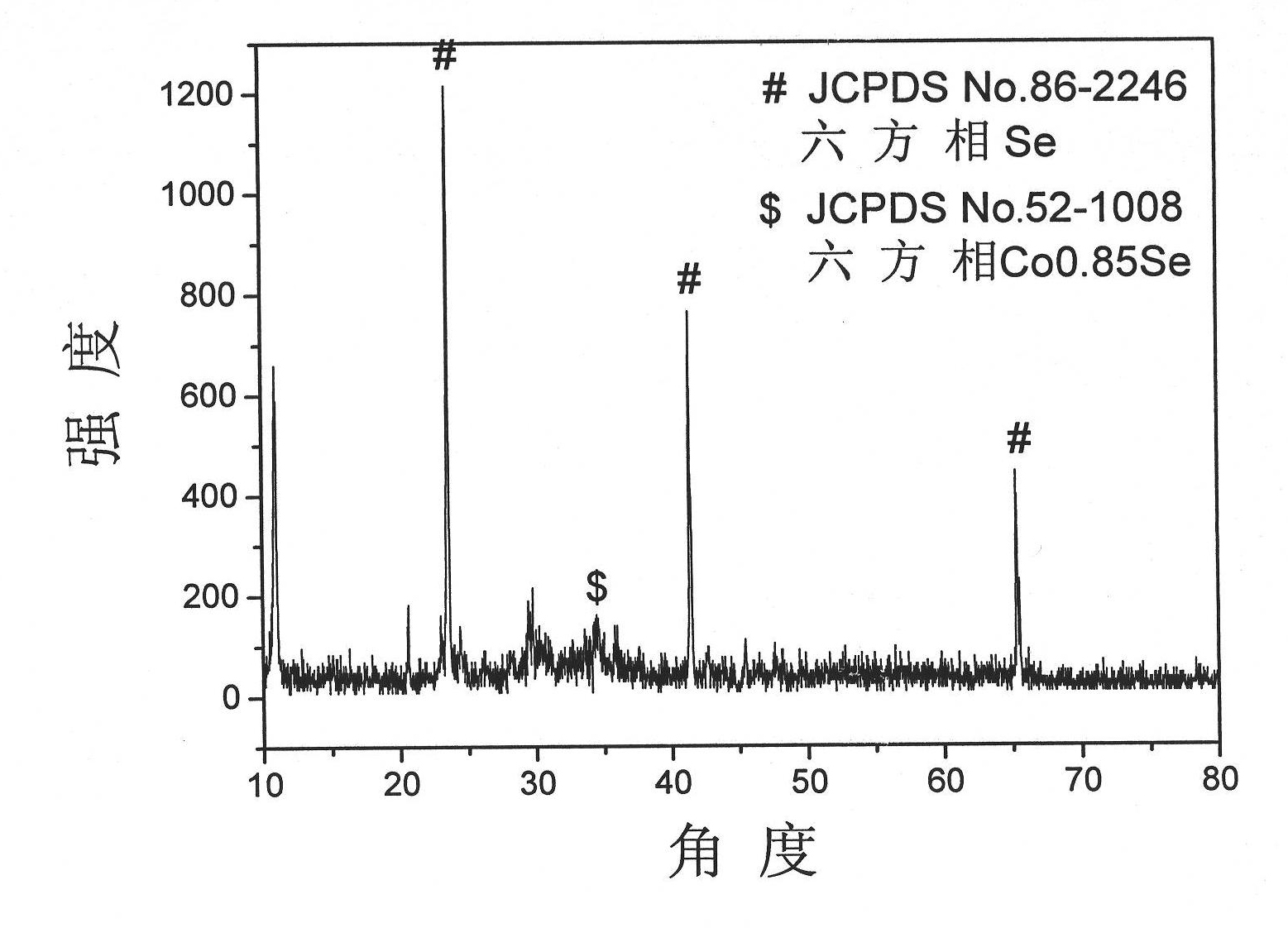

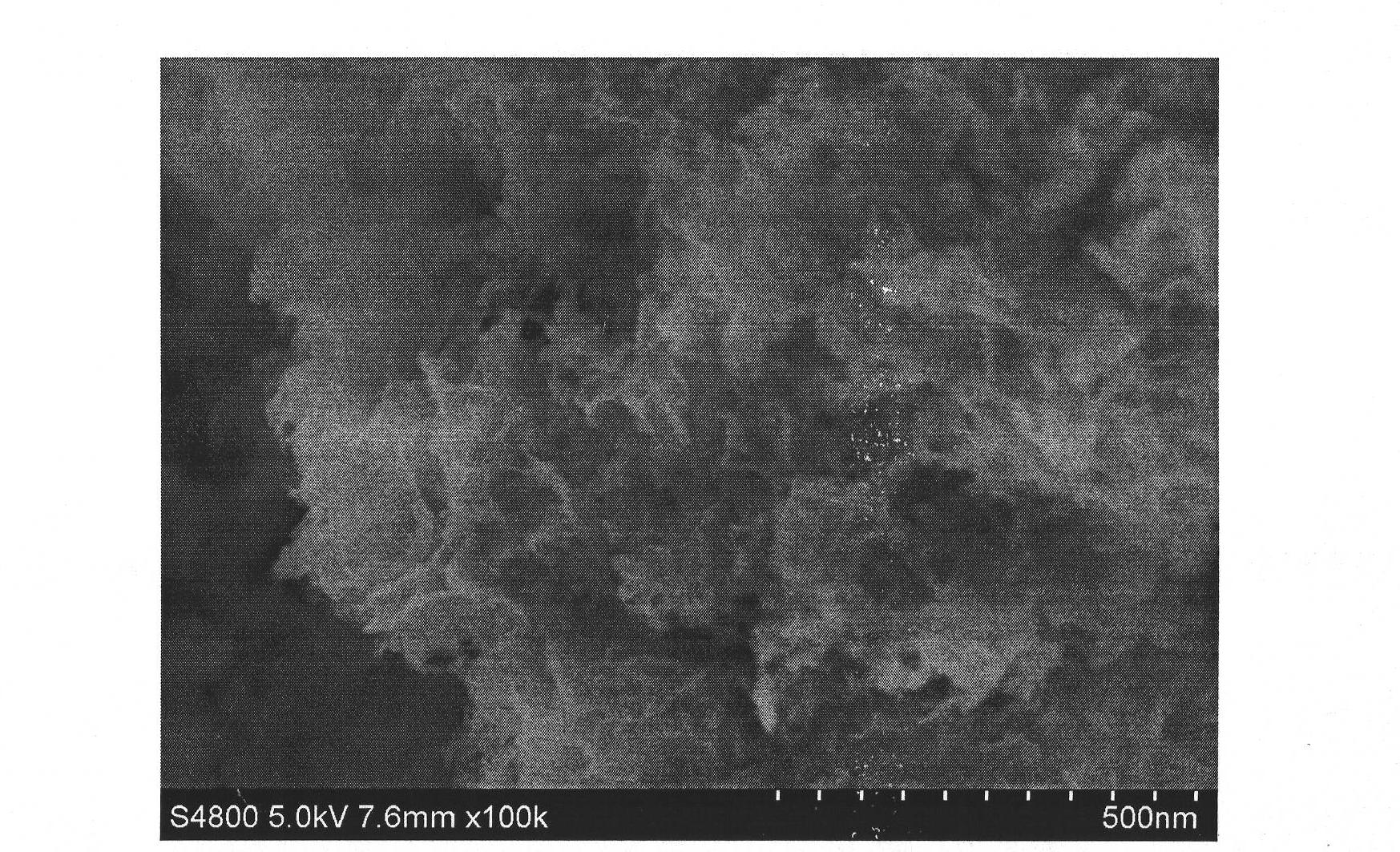

[0032] The phase of the sample was characterized by Philips X'Pert PRO SUPER X-ray diffractometer (XRD), the morphology of the sample was characterized by the Hitachi scanning microscope S4800 in Japan, and the nature of the organic dye adsorption of the sample was tested by Shimadzu-3600 The specific surface area and micropore distribution of the samples were analyzed by a fully automatic microporous physical adsorption a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com