Ammonium chloride anti-blocking agent composition and application

An anti-caking agent, ammonium chloride technology, applied in the application, fertilizer mixture, ammonium salt fertilizer and other directions, can solve the problems of complex preparation, high cost, large amount of anti-caking agent added, etc., and achieves simple use and cost of use. Low, good anti-caking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

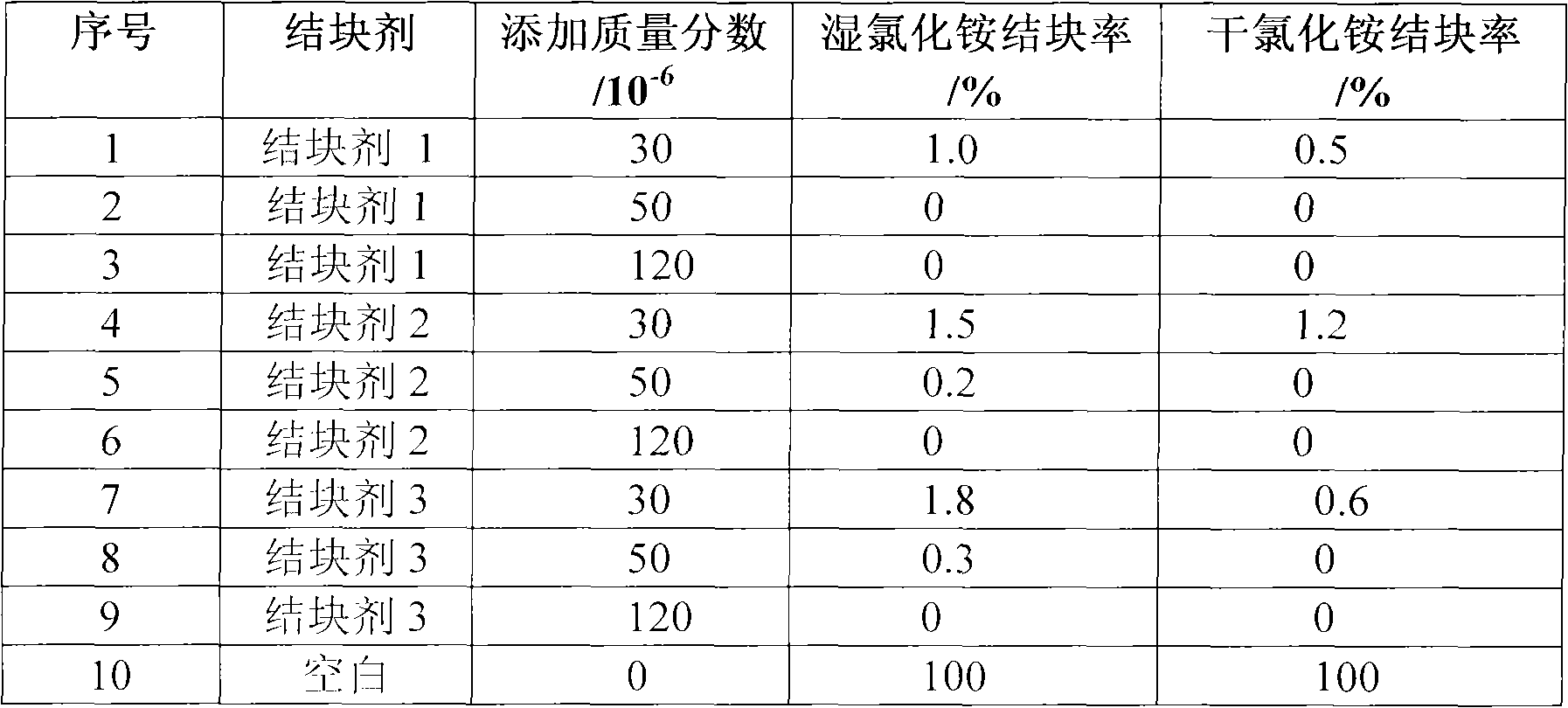

Embodiment 1

[0028] Weigh 1 kg of the above-mentioned maleic anhydride-acrylic acid polymer, 1 kg of potassium polyacrylate, 1 kg of potassium polyaspartate (the weight ratio of solid content is 1:1:1), 1.5 kg of sodium dodecyl diphenyl ether disulfonate g (0.05% of the total weight of the composition) was poured into a mixing tank and mixed uniformly to obtain the ammonium chloride anti-caking agent composition 1.

Embodiment 2

[0030] Weigh 0.5kg of the above-mentioned maleic anhydride-acrylic acid polymer, 1.5kg of potassium polyacrylate, 1.5kg of potassium polyaspartate (containing solid weight ratio 0.5: 1.5: 1.5), and dodecyl diphenyl ether disulfone 3.5 grams of sodium chloride (0.1% of the total weight of the composition) was poured into a mixing tank and mixed uniformly to obtain the ammonium chloride anti-caking agent composition 2.

Embodiment 3

[0032] Take by weighing 0.8kg of the above-mentioned maleic anhydride-acrylic acid polymer, 1.2kg of potassium polyacrylate, 0.8kg of potassium polyaspartate (containing solid weight ratio 0.8:1.2:0.8), and dodecyl diphenyl ether disulfone Sodium bicarbonate 2g (0.07% of the total weight of the composition) was poured into a mixing tank and mixed uniformly to obtain the ammonium chloride anti-caking agent composition 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com