Steel wire heat treatment open-fire heating furnace with column combined type preheater

A preheater and heating furnace technology, which is applied in heat treatment furnaces, heat treatment equipment, lighting and heating equipment, etc., can solve the problems of excessive air volume in the soaking section, affecting the quality of steel wires, poor accuracy of hot air valves, etc. High utilization rate of heat energy and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

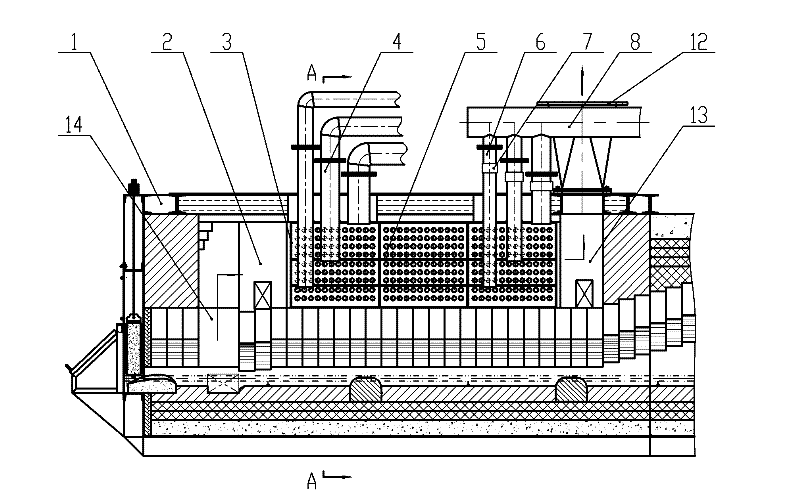

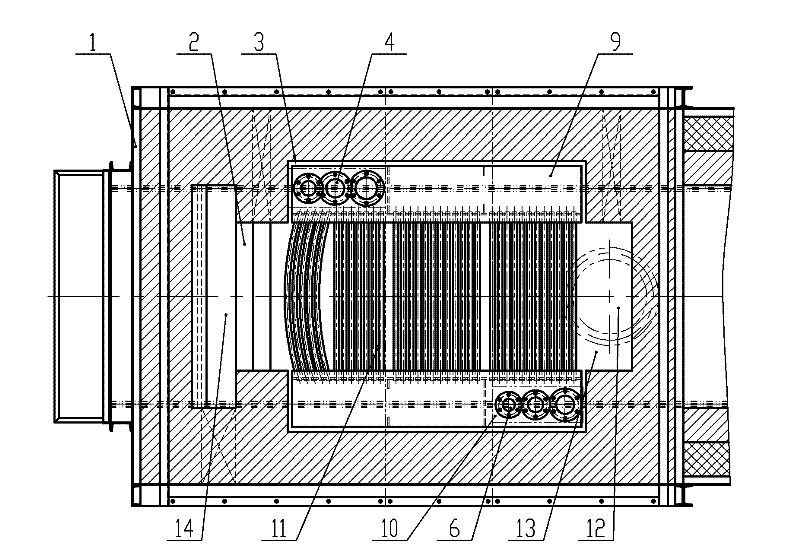

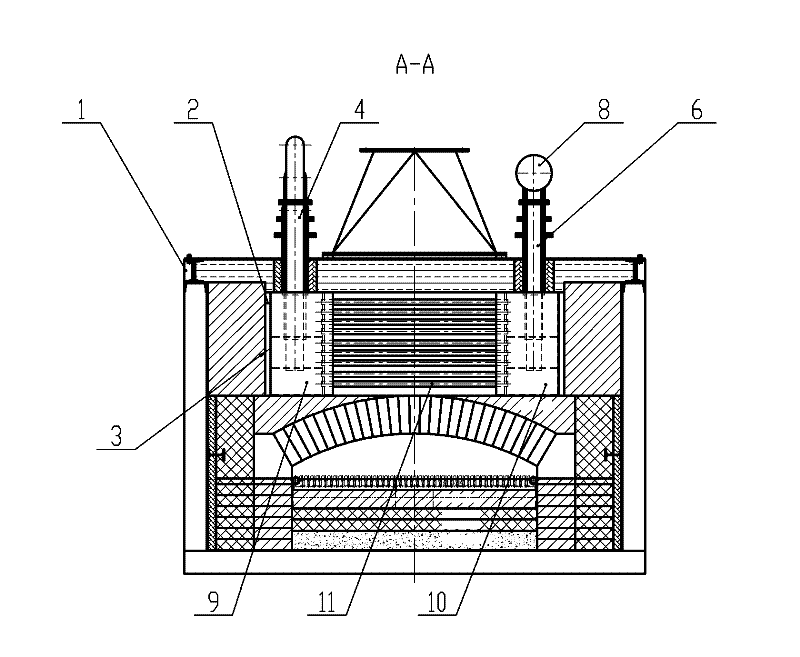

[0014] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Figure 1~Figure 3 Including open flame heating furnace 1, exhaust flue 2, preheater 3, hot air pipe 4, clapboard 5, cold air pipe 6, cold air valve 7, cold air main pipe 8, hot air box 9, cold air box 10, connecting ventilation pipe 11. Chimney 12, flue gas outlet 13, flue gas inlet 14, etc.

[0016] Such as Figure 1~Figure 3 As shown, the present invention is an open flame heating furnace for steel wire heat treatment with a combined preheater. A preheater 3 is arranged in the exhaust flue 2 of the open flame heating furnace 1 .

[0017] The preheater 3 is a split type preheater, including a hot air box 9 and a cold air box 10 communicated by a connecting ventilation pipe 11 . The hot air box 9 and the cold air box 10 are divided into a plurality of chambers by partitions 5 respectively. Each chamber of the hot air box 9 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com