In vivo absorbable metal intervertebral fusion cage

A technology of intervertebral fusion device and fusion device, applied in the direction of internal fixator, internal bone synthesis, prosthesis, etc., to achieve the effect of relieving pain, maintaining support height, and realizing intervertebral bone healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

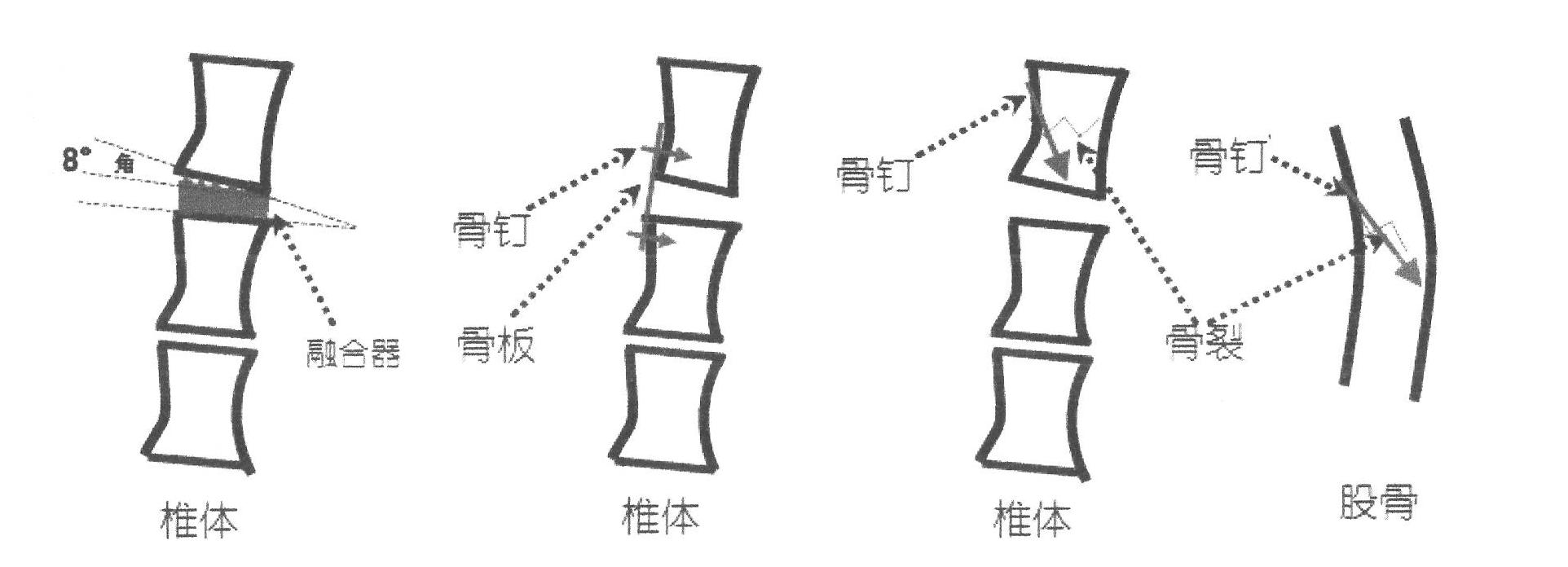

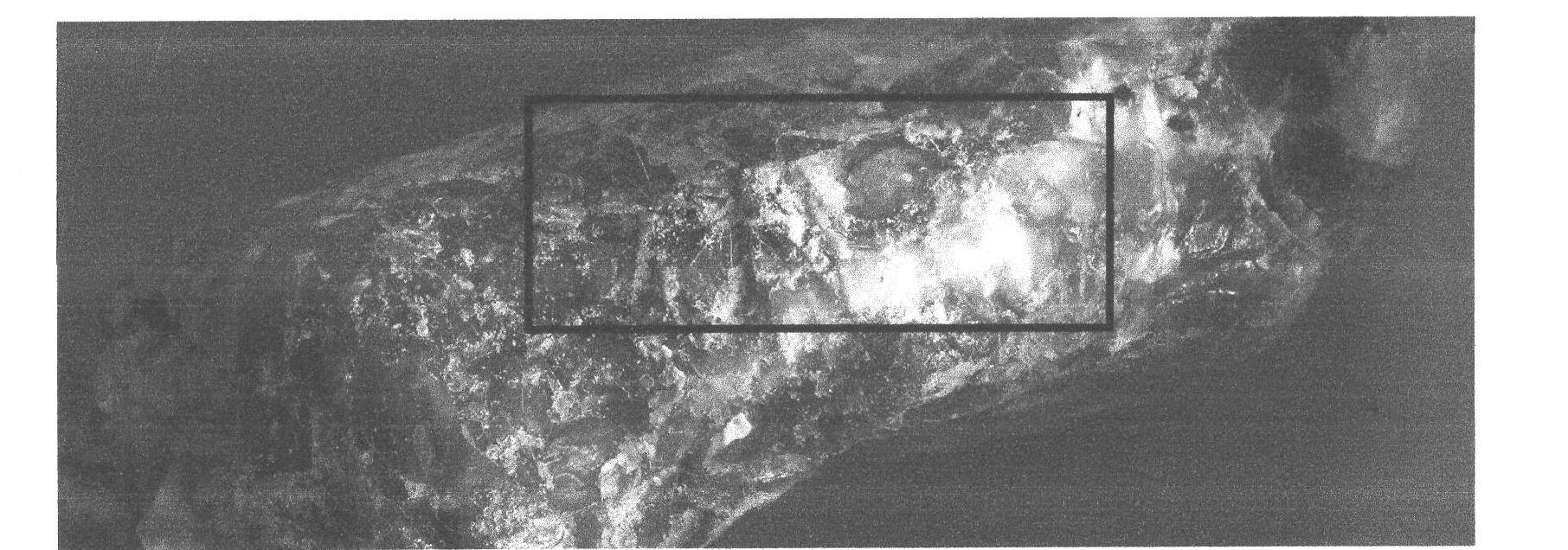

[0031] The in vivo absorbable metal intervertebral fusion cage is made of pure magnesium with a purity of 99.9%. The size of the fusion cage prepared in this example is 8mm×5mm, the wall thickness is 1mm, and the height is 7mm. The angle between the upper side of the fusion cage and the horizontal angle is 8°( figure 1 ), adapted to the natural curvature of the sheep cervical spine, two fusion devices are required to be placed into the posterior edge of the distracted vertebral body, and applied to larger defects. figure 2 About three months after implantation in the cervical spine of the sheep, the sheep was sacrificed, and the implantation site was taken out. The exact place of implantation is shown in the box. It can be seen from the macroscopic state that the tissue around the implantation site has healed well. The organization is the same. It shows that the biocompatibility of the pure magnesium intervertebral fusion device is good after implantation.

Embodiment 2

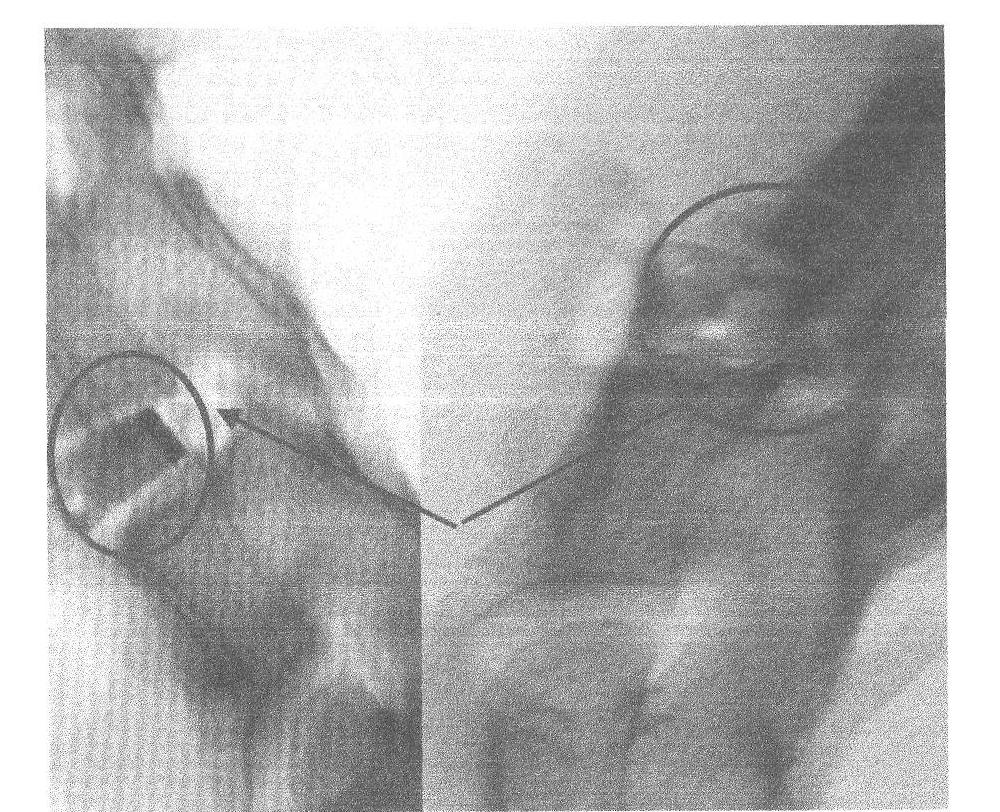

[0033] The body absorbable metal intervertebral fusion device is made of Mg-Zn alloy, the mass content of magnesium is 10%-100%, and the total content of Zn element is 0-90%. The size of the fusion vessel prepared in this example is 14mm×13mm, the wall thickness is 2mm, and the height is 8mm. The preparation method is as follows: the Mg-Zn square with rounded corners is cut out by wire cutting, and the method of mechanically engraving with CNC machine tools Carve out the clamping teeth, and then use the wire cutting method to cut out two hollow parts and clamping holes, so as to avoid internal small cracks caused by thin-walled clamping. When using it, two fusion devices are used, placed into the posterior edge of the distracted vertebral body, and applied to larger defects. image 3 Degradation on the day of implantation (left) and one month after implantation (right) in the sheep cervical spine. On the day of implantation, the bone defect indicated by the arrow has been rep...

Embodiment 3

[0035] The absorbable metal intervertebral fusion cage in the body is made of Mg-Zn alloy, and the Zn content can be selected to be between 4-6±0.5%. After soaking in normal saline to lose weight, the change of three-point bending strength is tested, and the result is obtained. out Figure 4 is the curve of the three-point bending load decreasing with the weight loss rate. It proves that the mechanical properties of the magnesium alloy intervertebral fusion cage will be lost during the degradation process, and it needs to be adjusted by changing the alloy composition, tissue structure, coating, etc. to ensure the maintenance of the support height during the degradation process.

[0036] Using extruded Mg-Zn alloy, the size of the prepared cage is 14mm×13mm, the wall thickness is 2mm, and the height is 8mm. Engraving method carves out the locking teeth, and then cuts out a total of 2 hollow parts and clamping holes by wire cutting, and a total of 4 side wall openings, so as to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com