Chemical cleaning and chemical repairing method and system for waste reverse osmosis membrane

A reverse osmosis membrane and chemical cleaning technology, applied in the field of water treatment, can solve problems such as inability to monitor the performance of a single membrane, waste of chemical reagents, breakdown of reverse osmosis membrane, etc., to save cleaning time, reduce environmental load, and reduce difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

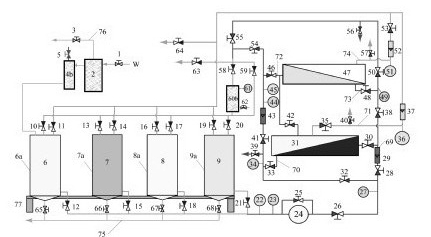

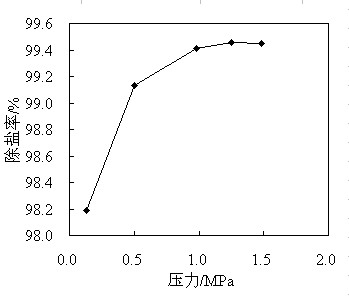

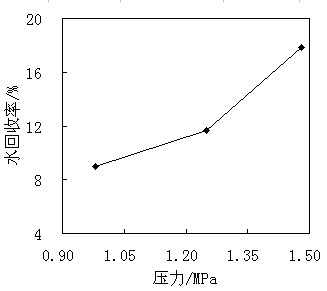

[0041] Utilize method and device of the present invention (see figure 1 ) to measure the performance of BW30-400 new reverse osmosis membrane. The experimental process is to use the tap water (6) pretreated by the activated carbon filter (2) and the first cartridge filter (4b) as the test solution to investigate the feed water conductivity of the new reverse osmosis membrane under different feed water pressures. Rate, freshwater conductivity, influent flow rate and freshwater flow rate change trend, the relevant data obtained are shown in Table 1. Based on these data, it is calculated as figure 2 , 3 The salt removal and water recovery curves (0.13~1.48MPa) of the new reverse osmosis membrane are shown.

[0042]

Embodiment 2

[0044] This example is the whole process of chemically cleaning the BW30-400 waste reverse osmosis membrane. After performing different cleaning steps, tap water (6) pretreated by the activated carbon filter (2) and the first cartridge filter (4b) was used as the test solution respectively, and the water inlet pressure was 1.20 and 1.50 MPa respectively. The feedwater conductivity, freshwater conductivity, feedwater flow rate, fresh water flow rate, feedwater pressure and concentrated water pressure of the reverse osmosis membrane were measured, and the experimental data and results in Tables 2 and 3 were obtained. Figure 4 various change curves. Based on these data, the main performance parameters of the spent RO membranes shown in Table 4 after different chemical cleaning steps were calculated.

[0045]

[0046]

[0047]

Embodiment 3

[0049] Utilize the method and device of the present invention to carry out chemical cleaning to CPA3-8040 high pressure differential old reverse osmosis membrane, the result is shown in Table 5. The characteristic of this membrane is that the initial pressure difference is too large, which is 1.25MPa, and the membrane has been blocked, so its initial desalination performance cannot be measured. After backwashing, the flow path of the membrane is opened. Subsequently, it was cleaned with an acidic cleaning solution, and the pressure difference gradually dropped to 0.17MPa, but its desalination rate and water recovery rate were still low, 71.9% and 11.4% respectively, so an alkaline cleaning solution was used to clean it. Cleaning was carried out. Alkaline cleaning is mainly to remove organic matter, colloid, and SiO on the surface of the membrane 2 Wait. After alkaline washing, the desalination rate drops to 69.9%, the water recovery rate rises to 19.2%, and the pressure dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com