Metering packer of convenient snack food

A technology for measuring packaging and packaging machines, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of no measurement function, high cost, and many labor, and achieve the effect of saving labor, rapid measurement, and accurate and rapid measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

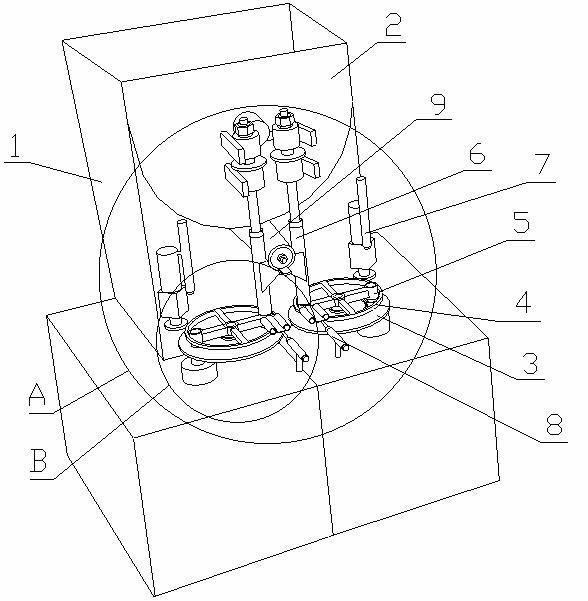

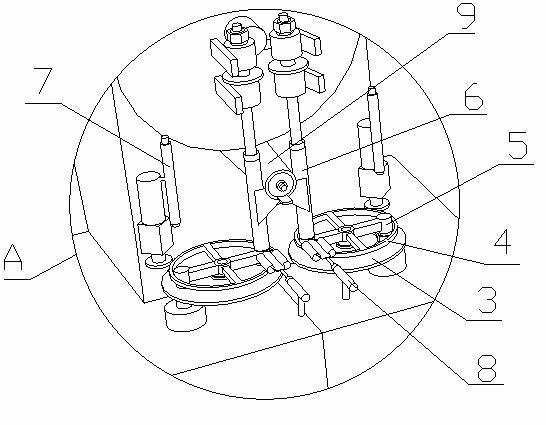

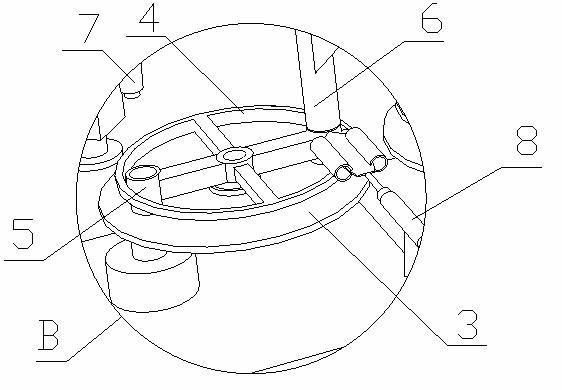

[0026] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 : A kind of measuring and packaging machine for convenient snacks, which is composed of a metering device, a packaging machine and an automatic control device. The chassis 3 is provided with a turntable 4, the turntable 4 is driven by a stepping motor, every step, the turntable 4 rotates 180 °, the turntable 4 is provided with a pair of vertical measuring cylinders 5, and the measuring cylinders 5 are on the same side of the turntable 4 On the diameter, it is symmetrically distributed relative to the center of the circle, the lower mouth of the measuring cylinder 5 is flush with the surface of the turntable 4, and there are a charging position 61 and a discharging position 71 corresponding to the initial positions of the two measuring cylinders 5 on the chassis 3. 61 is provided with a pressure sensor, which is used to detect the quality or density of the material in the measuring cylinder 5. At the discharge...

Embodiment 2

[0043] Embodiment 2: Above the charging position 61 measuring cylinder 5, a vertical electric push screw 6 is provided. Into measuring cylinder 5, all the other are identical with embodiment 1.

[0044] In actual production, according to actual demand and working speed, multiple metering devices can be arranged side by side, and the through holes of their discharge positions 71 are connected to the packaging machine.

[0045] The used packing machine of the present invention, according to production needs, can select bag packing machine for use, or select bottle packing machine for use, all is the stereotyped product that is currently commercially available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com