AOA (Angles-Of-Arrival) continuous flow biological nitrogen and phosphorus removal process for sewage treatment

A biological denitrification and sewage treatment technology, applied in the field of sewage treatment process, can solve the problems of large amount of carbon source input, high energy consumption in operation, low efficiency of simultaneous denitrification and phosphorus removal, etc., to achieve improved utilization efficiency and low energy consumption , the effect of saving dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

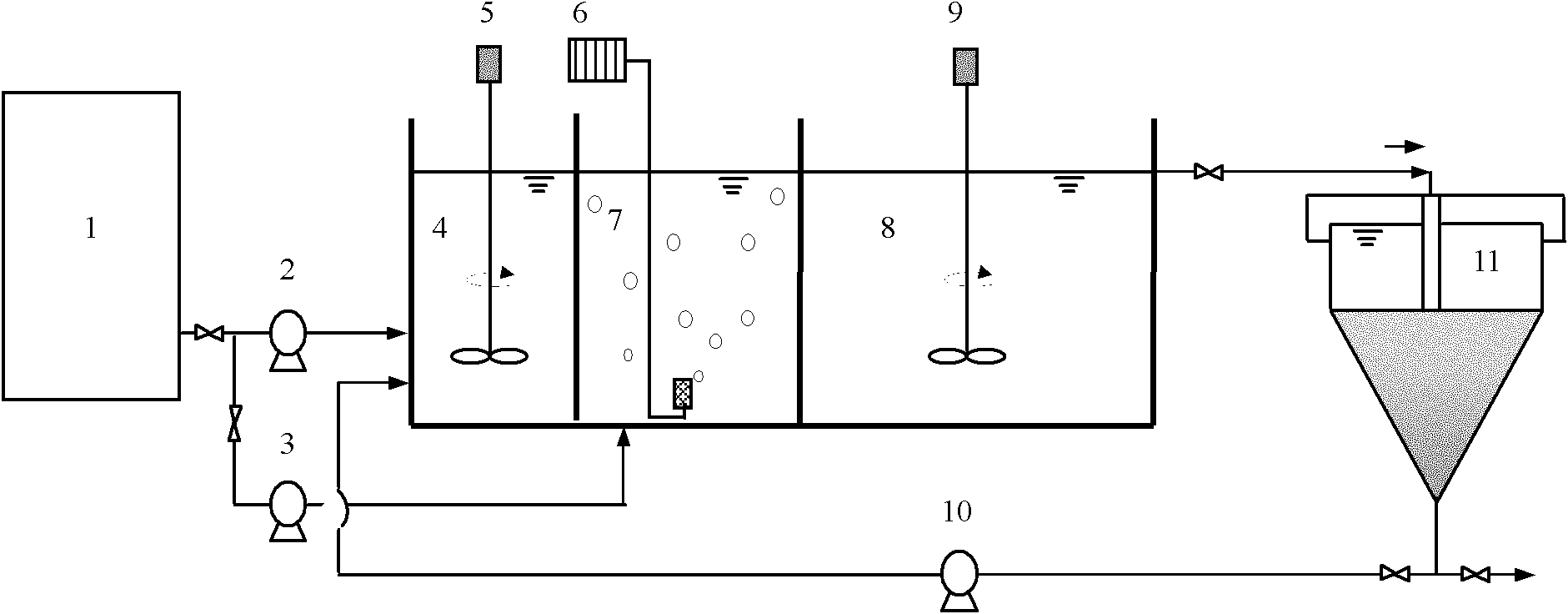

[0016] Specific implementation mode one: combine figure 1 As shown, the AOA continuous flow biological denitrification and dephosphorization process used for sewage treatment in this embodiment is carried out in the following steps: 1. The effluent from the primary sedimentation tank is divided into two parts through the water distribution well, and enters the anaerobic tank 4 and the aerobic tank 7 respectively, At the same time, the sludge from the secondary sedimentation tank flows back to the beginning of the anaerobic tank 4 through the sludge return pump 10 to form a mud-water mixture; 2. The mud-water mixture enters the aerobic tank 7 from the anaerobic tank 4 according to the push flow method, and then enters the anoxic tank 8. Enter the secondary settling tank 11 after mixed reaction, carry out sedimentation and drainage, and complete AOA continuous flow biological denitrification and phosphorus removal;

[0017] Wherein in step 1, the effluent of the primary sediment...

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the aerobic tank 7 is provided with a microporous aeration head for aeration, so that the mixed liquid fluctuates up and down and mixes evenly, and the dissolved oxygen concentration is 1.5 mg / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the anaerobic pool 4, the aerobic pool 7, and the anoxic pool 8 in the step 2 are all provided with partition wall classification, so that it forms a plug-flow treatment form, collectively referred to as the reaction Zone, in which the anaerobic pool 4, aerobic pool 7, and anoxic pool 8 are separated by 4, 7, and 4 respectively, the volume ratio is 3:4:5, the total hydraulic retention time of the reaction area is 8h, and the temperature of the reaction area is 25~27℃. Other steps and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com