Method for hydrothermally synthesizing strontium and yttrium multi-doped barium titanate multilayer ceramic capacitor ceramic powder

A technology of capacitor ceramics and hydrothermal synthesis, which is applied in the direction of fixed capacitor dielectric and fixed capacitor parts, can solve the problems of unsatisfactory powder performance and serious powder hard agglomeration, so as to avoid hard powder agglomeration and powder The effect of small crystal grains and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

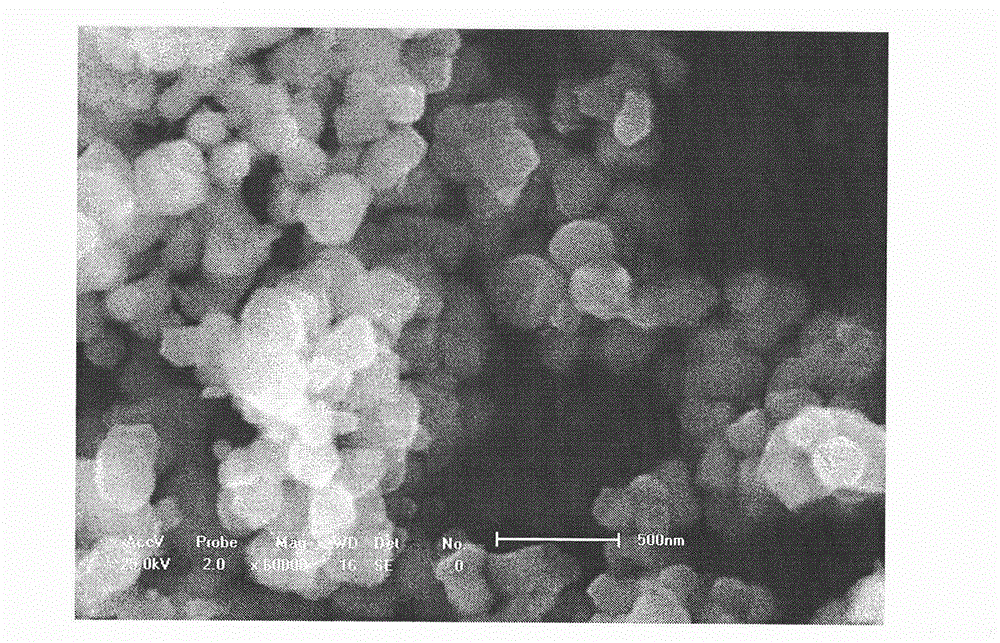

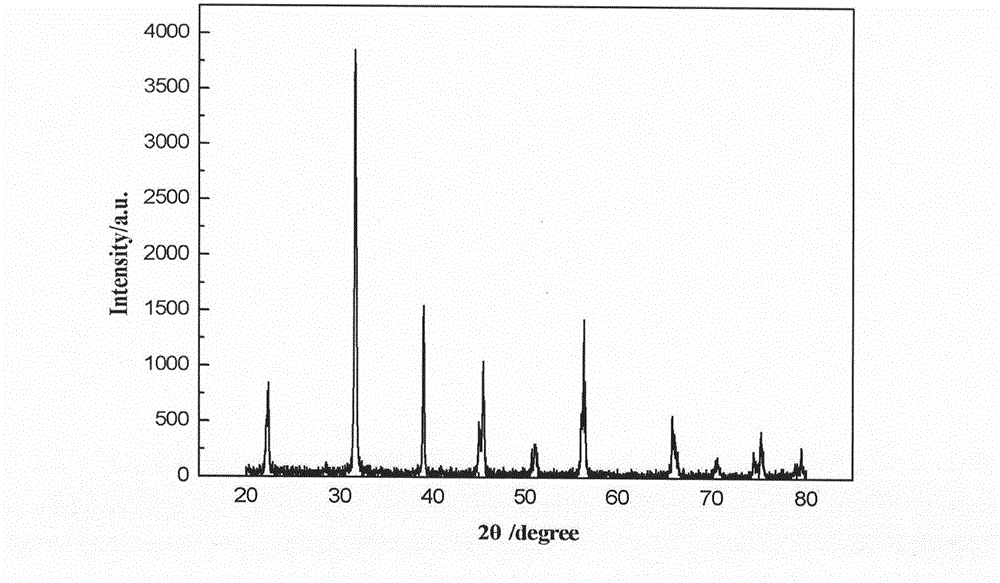

[0020] Implementation steps of the method for hydrothermally synthesizing strontium, yttrium multi-doped barium titanate multilayer ceramic capacitor ceramic powder:

[0021] 1) with TiO 2 、Ba(OH) 2 ·8H 2 O, Sr(OH) 2 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O is the raw material, according to Ba:Ti=1~5, Sr(OH) 2 and Y(NO 3 ) 3 The proportions relative to the molar ratio of Ba were 5% and 3% batching, respectively.

[0022] 2) Dissolving the reaction precursor at 80-100° C. to form a homogeneous solution. And adding a NaOH solution with a concentration of 3 mol / L to adjust the pH value of the precursor solution in the range of 10-14.

[0023] 3) Move the homogeneous solution of the precursor to a high-pressure reactor and keep it warm for 20-36 hours under the condition of hydroheating at 200-250°C.

[0024] 4) centrifuging the mixed solution after the reaction.

[0025] 5) Wash the separated solution once with methylpyrrolidone, then with absolute ethanol, and finally with deio...

Embodiment 2

[0028] Implementation steps of the method for hydrothermally synthesizing strontium, yttrium multi-doped barium titanate multilayer ceramic capacitor ceramic powder:

[0029] 1), with TiO 2 、Ba(OH) 2 ·8H 2 O, Sr(OH) 2 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O is the raw material, according to Ba:Ti=1~5, Sr(OH) 2 and Y(NO 3 ) 3 The proportions relative to the molar ratio of Ba were 3% and 2% batching, respectively.

[0030] Other steps are with embodiment 1.

Embodiment 3

[0032] Implementation steps of the method for hydrothermally synthesizing strontium, yttrium multi-doped barium titanate multilayer ceramic capacitor ceramic powder:

[0033] 1), with TiO 2 、Ba(OH) 2 ·8H 2 O, Sr(OH) 2 ·6H 2 O, Y (NO 3 ) 3 ·6H 2 O is the raw material, according to Ba:Ti=1~5, Sr(OH) 2 and Y(NO 3 ) 3 The proportions relative to the molar ratio of Ba were 7% and 5% of the ingredients.

[0034] Other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com