Hose and cable winding system of mobile tank cleaning robot

A robotic and mobile technology, which is applied in the direction of cleaning hollow objects, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of low oil and gas recovery rate, long construction period, high labor intensity, etc., and achieve a high degree of automation and improve The effect of productivity and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

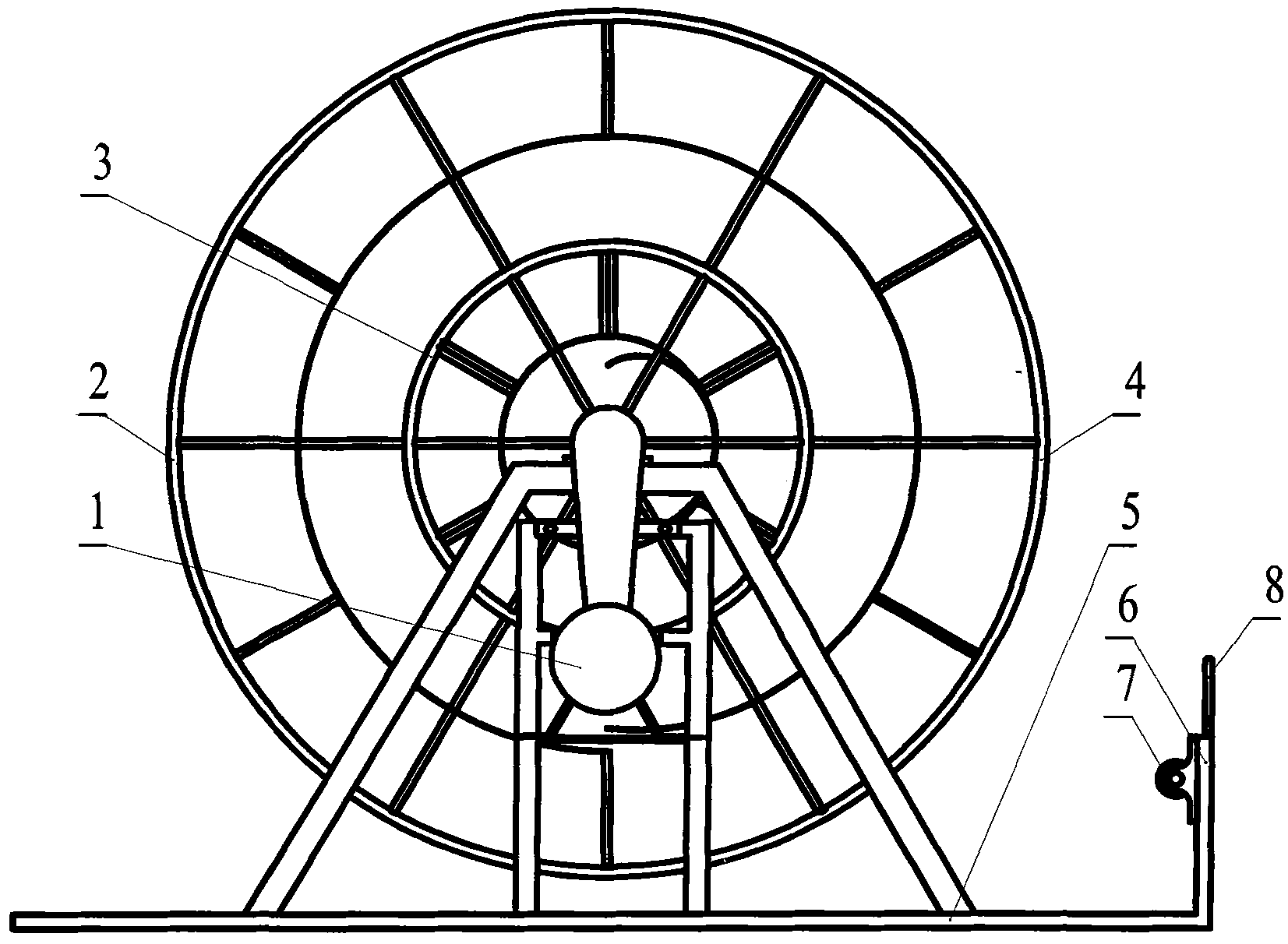

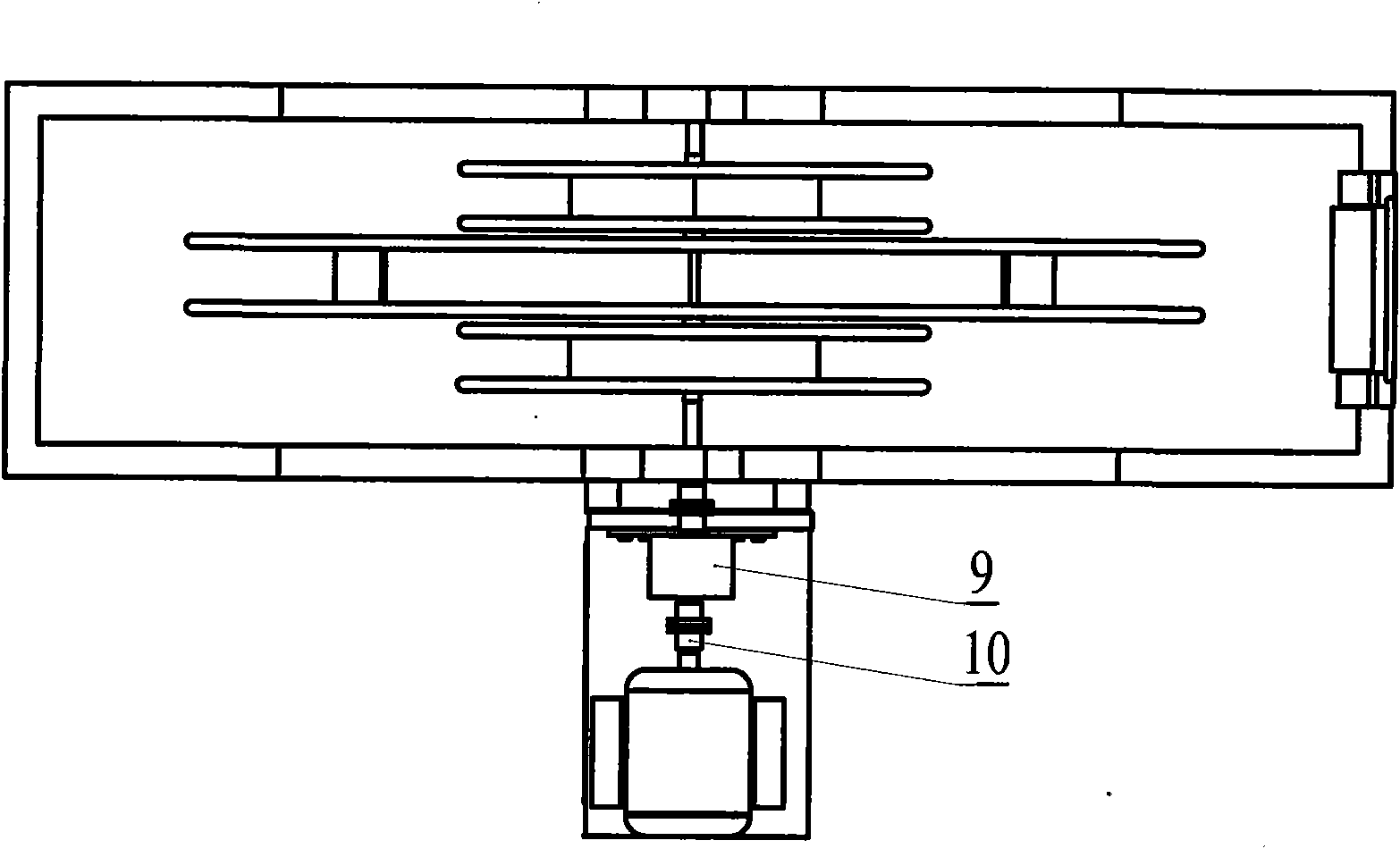

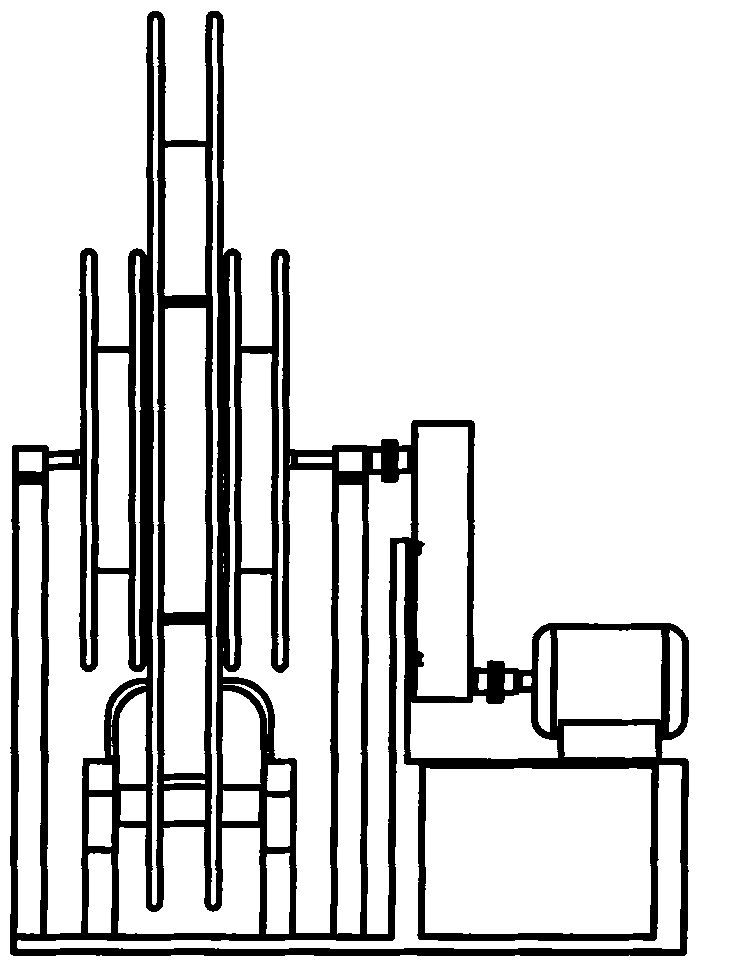

[0017] see Figure 4 , The tank cleaning system includes a mobile tank cleaning robot, sludge suction system, cleaning pump, hydraulic pump station and remote control console, hose and cable reel. Hose and cable reels see figure 2 , including power unit 1, main and auxiliary reels 2, 3, liftable cable guide frame 6 and other parts, auxiliary equipment for the mobile tank cleaning robot system, located between the tank cleaning robot, the hydraulic pump station and the remote console . The hose cable coming out of the main reel 2 is connected with the tank cleaning robot, the hose cable coming out of the auxiliary reel 3 is connected with the hydraulic pump station and the console, and the hose cable is wound outside the main and auxiliary reel The cables on the main and auxiliary reels are connected through the inner ring, because the number of hoses and cables is large, thus omitting complicated rotary joints and collector slip rings. The length of the hose cable is distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com