Laser processing device

A laser processing and laser technology, applied in auxiliary devices, metal processing, laser welding equipment, etc., can solve unsolvable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, preferred embodiments of the laser processing apparatus configured according to the present invention will be described in more detail with reference to the drawings.

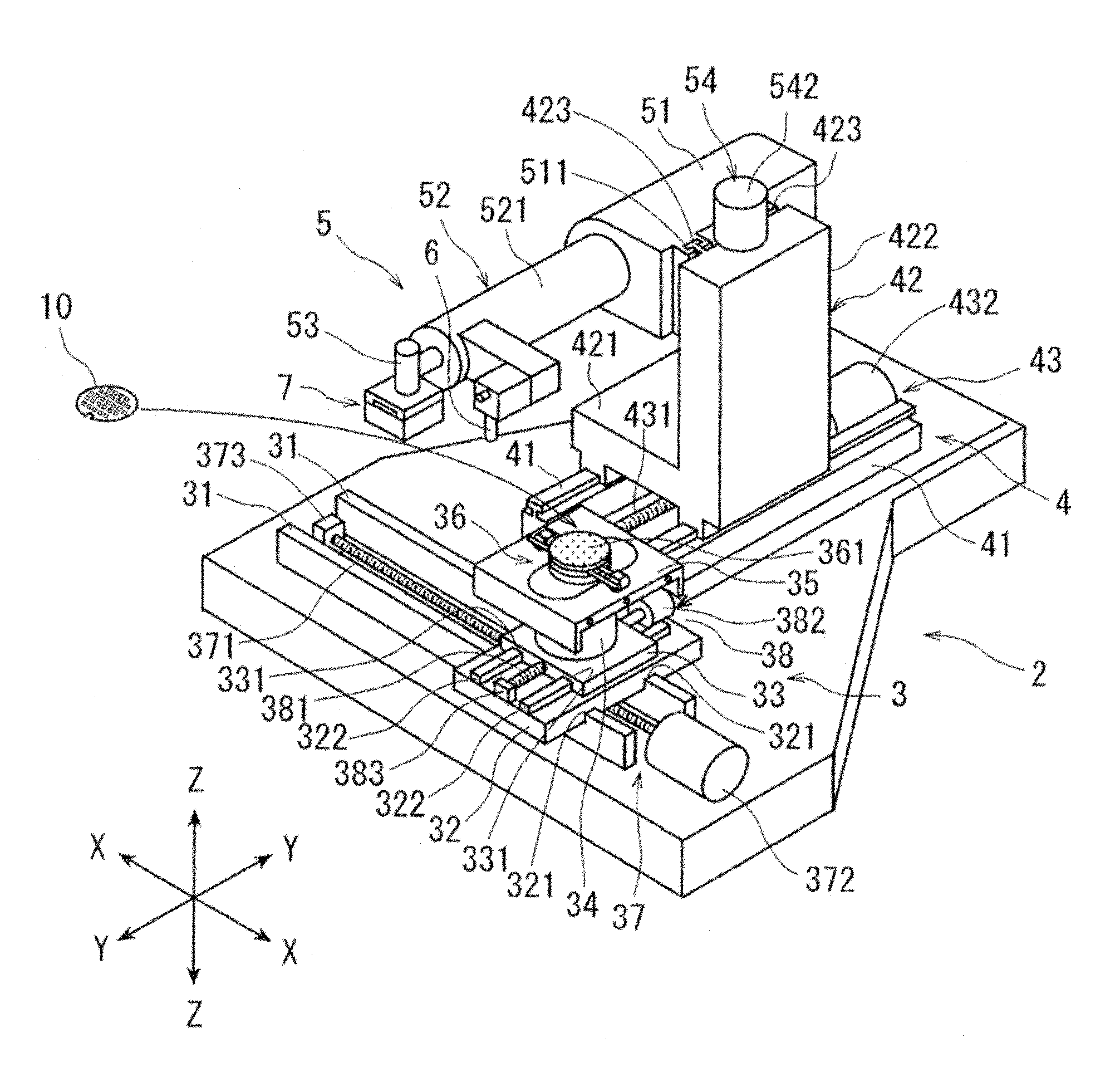

[0026] exist figure 1 A perspective view of a laser processing device constructed according to the present invention is shown in . figure 1 The shown laser processing device is equipped with: a stationary base 2; a chuck table mechanism 3, which is arranged on the stationary base 2 in a manner capable of moving along the processing feed direction shown by the arrow X, and is used to hold the workpiece to be processed. object; a laser light irradiation unit support mechanism 4, which is arranged on the stationary base 2 in a manner capable of moving along the indexing feed direction shown by the arrow Y that is at right angles to the direction shown by the above arrow X; and laser light irradiation The unit 5 is disposed on the laser beam irradiation unit support mechanism 4 so as to be mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com