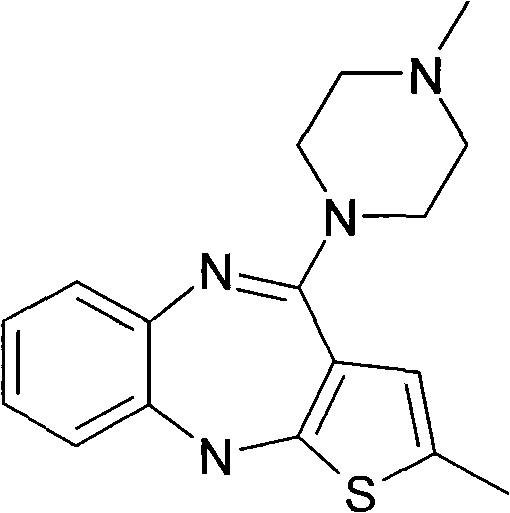

A kind of method for preparing olanzapine crystal form Ⅱ

A technology of olanzapine and crystal form, applied in organic chemistry and other directions, can solve the problems of prolonging drying time, high acetonitrile residue, reducing residual solvent, etc., to achieve the goal of reducing residual amount, good product purity, and conducive to market competition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

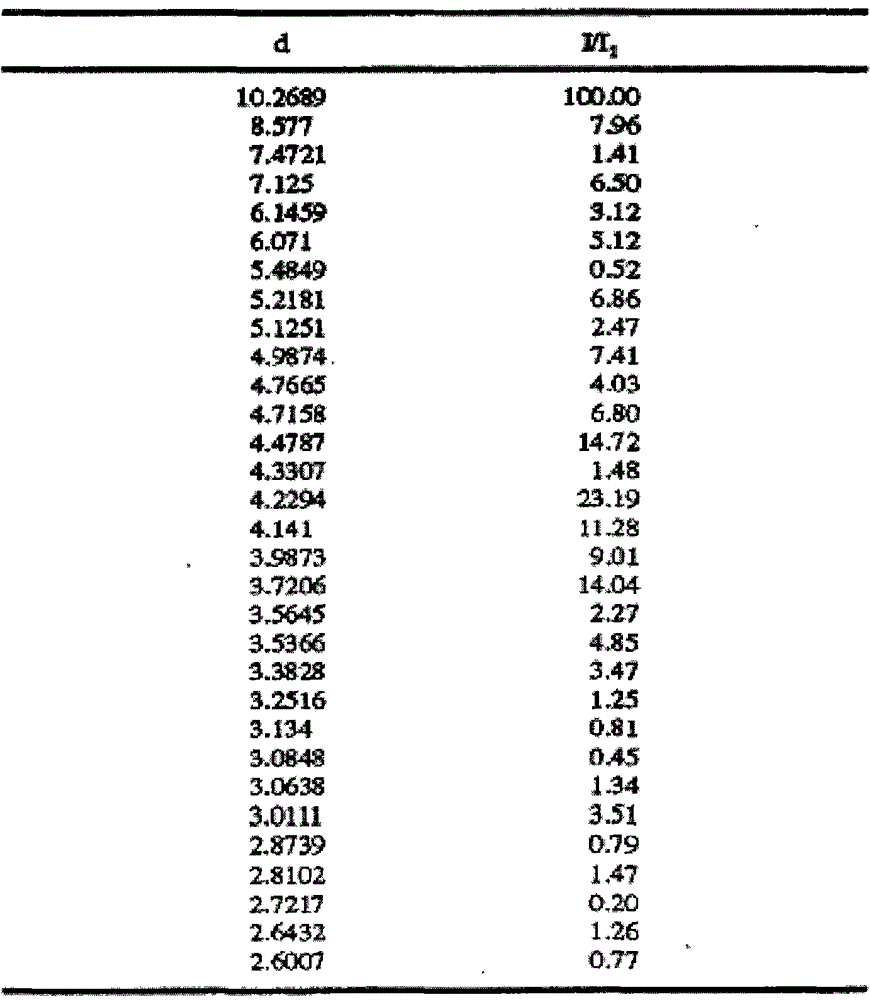

[0023] Example 1: Preparation of Olanzapine Form II

[0024] Add 10 g of crude olanzapine into 120 ml of acetonitrile, heat until dissolved, add 0.5 g of activated carbon, heat to reflux and keep stirring for 30 min under reflux. Filtrate while hot, slowly cool down the filtrate to 70°C and keep it warm at 65-70°C for 2 hours, then slowly cool it down to 55°C and keep it at 50-55°C and stir for 1.5 hours, then lower the temperature to 35°C within 1 hour and keep it warm for 30 Stir at ~35°C for 0.5 hours, finally cool down to 0-5°C and keep stirring for 1.5 hours, then filter. Add 30ml of ethyl acetate to the filter cake, heat to 60°C, stir and wash for 3 hours, then slowly cool down to 0-5°C and keep stirring for 1.5 hours, then filter. After the filter cake was dried, 9.1 g of solid was obtained, which was tested as olanzapine crystal form II, with a HPLC purity of 99.96%, 217 ppm of ethyl acetate and 255 ppm of acetonitrile.

Embodiment 2

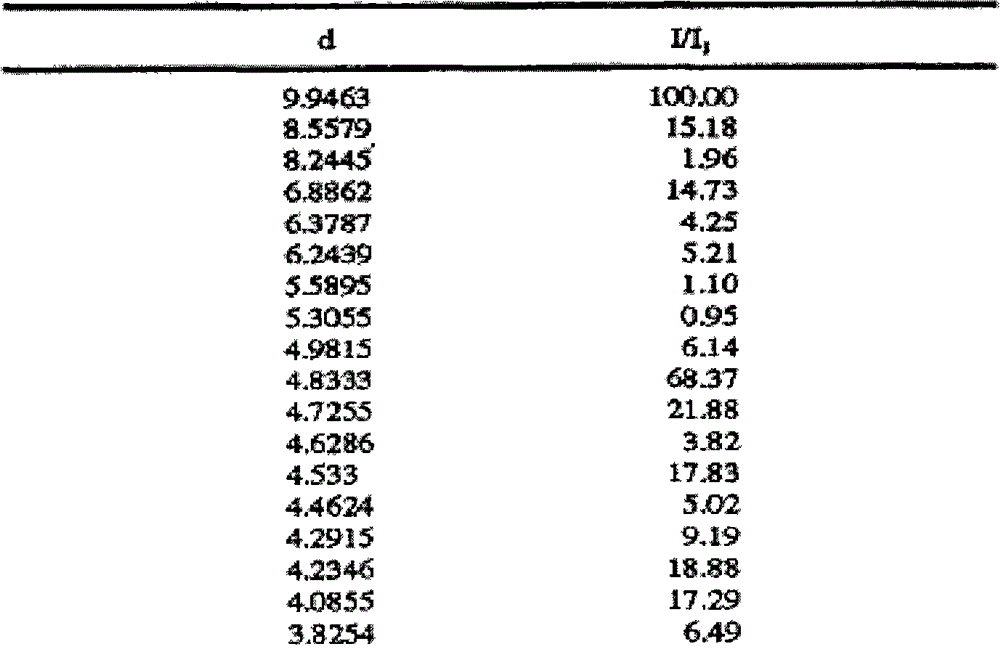

[0025] Example 2: Preparation of Olanzapine Form II

[0026] Add 10 g of crude olanzapine into 120 ml of acetonitrile, heat until dissolved, add 0.5 g of activated carbon, heat to reflux and keep stirring for 30 min under reflux. Filtrate while hot, slowly cool down the filtrate to 70°C and keep it warm at 65-70°C for 2 hours, then slowly cool it down to 55°C and keep it at 50-55°C and stir for 1.5 hours, then lower the temperature to 35°C within 1 hour and keep it warm for 30 Stir at ~35°C for 0.5 hours, finally cool down to 0-5°C and keep stirring for 1.5 hours, then filter. Add 30ml of toluene to the filter cake, heat to 60°C, stir and wash for 3 hours, then slowly cool down to 0-5°C and keep stirring for 1.5 hours, filter, and dry the filter cake to obtain 9.2g of solid, which is olanzapine crystal form after inspection II, HPLC purity 99.95%, residual toluene 209ppm, residual acetonitrile 305ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com