Iron ore dust suppressant composition

A dust suppressant, iron ore technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of destroying the ecology along the line, polluting the environment along the line with mineral dust, destroying the ecology of animals and plants along the line, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

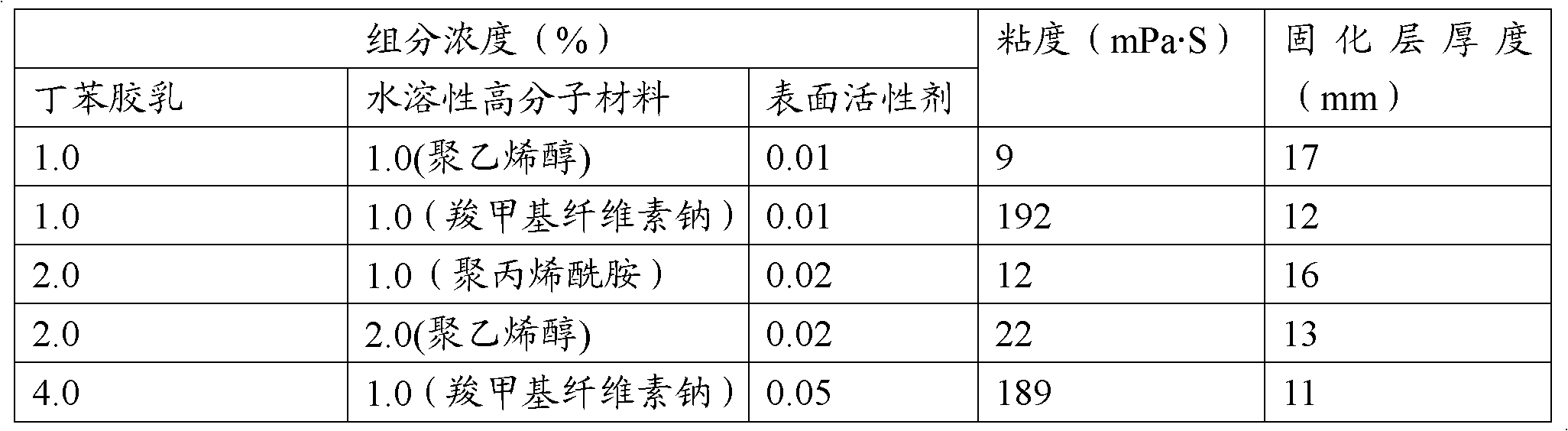

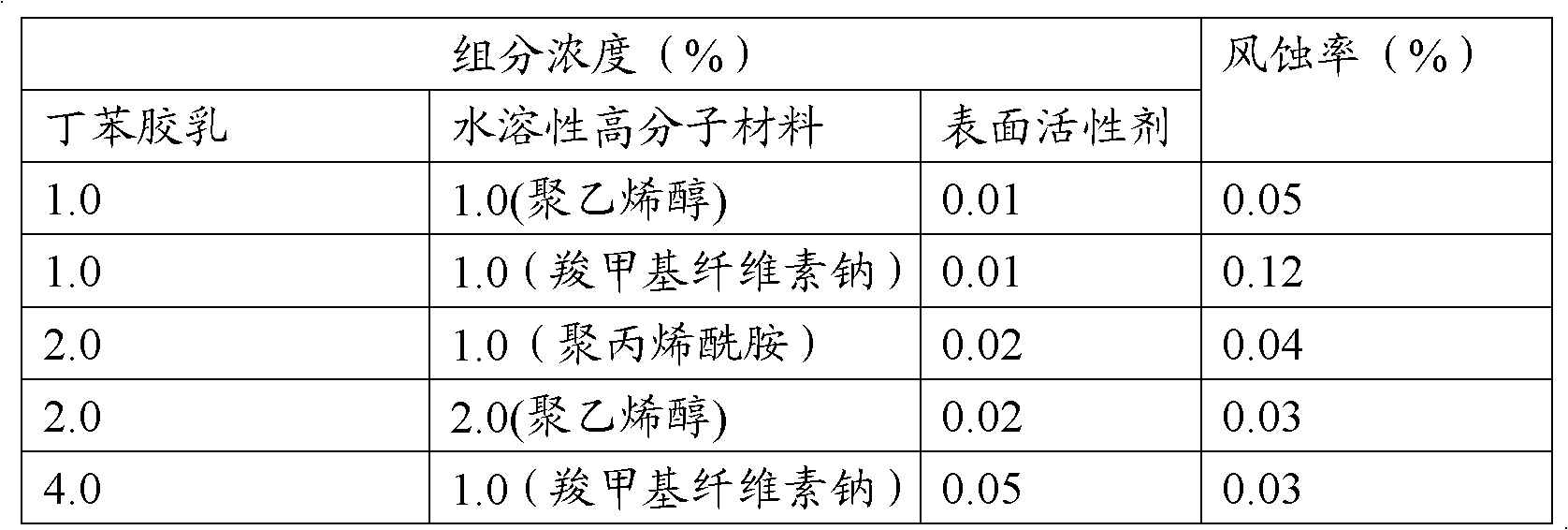

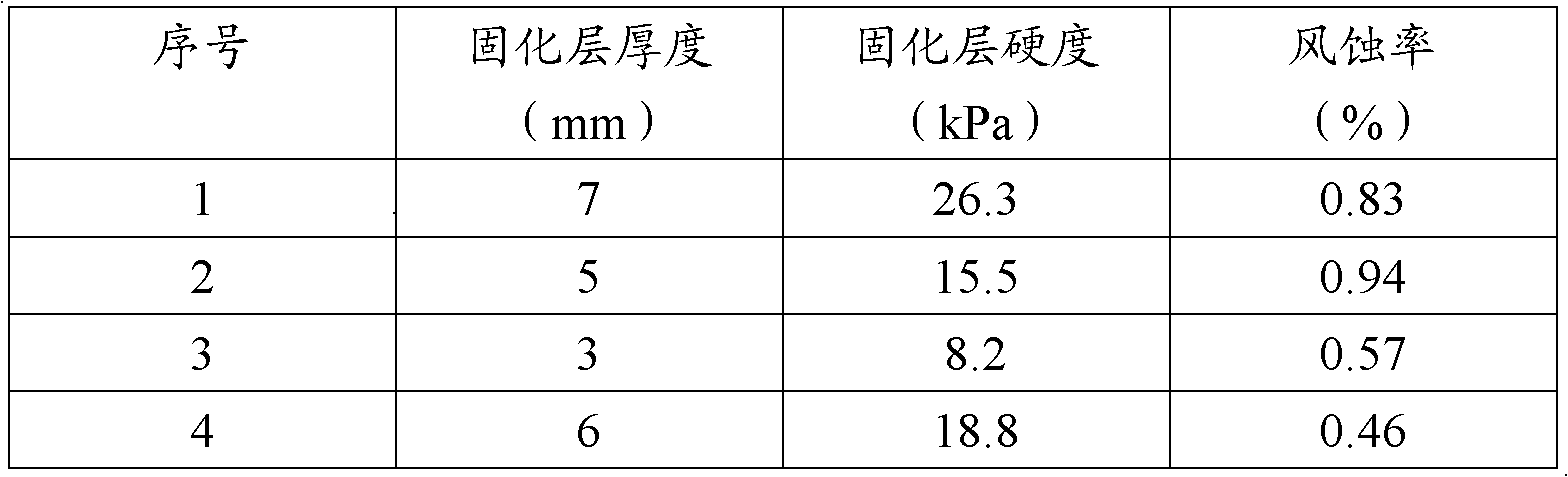

[0082] Example 1: Iron ore dust suppressant of the present invention

[0083] The preparation method is as follows:

[0084] A, 5.0 parts by weight of sodium carboxymethyl cellulose water-soluble polymer material are dissolved with 200 parts by weight of water to obtain a solution;

[0085] B, in the described solution, add 1.0 parts by weight of styrene-butadiene latex;

[0086] C, then add 0.001 parts by weight of coconut oil fatty acid diethanolamide surfactant, stir to obtain iron ore dust suppressant of the present invention.

[0087] The viscosity of the iron ore dust suppressant was 352 mPa·S, the thickness of the solidified layer was 11 mm, and the hardness of the solidified layer was 63.2 kPa by the method described in this specification.

[0088] The iron ore dust suppression effect of the iron ore dust suppressant was measured by the method described in this specification, and the wind erosion rate was 0.21%.

Embodiment 2

[0089] Example 2: Iron ore dust suppressant of the present invention

[0090] The preparation method is as follows:

[0091] A, 0.5 parts by weight of polyvinyl alcohol (degree of polymerization 1700, degree of alcoholysis 88) water-soluble polymer material is dissolved with 100 parts by weight of water to obtain a solution;

[0092] B, in the described solution, add 1.0 parts by weight of styrene-butadiene latex;

[0093] C, then add 1.0 parts by weight of sodium dodecylbenzenesulfonate surfactant, stir to obtain the iron ore dust suppressant of the present invention.

[0094] The viscosity of the iron ore dust suppressant of 11 mPa·S, the thickness of the solidified layer of 17 mm and the hardness of the solidified layer of 37.1 kPa were measured by the methods described in this specification.

[0095] Using the method described in this specification, the iron ore dust suppression effect of the iron ore dust suppressant was measured, and the wind erosion rate was 0.13%.

Embodiment 3

[0096] Example 3: Iron ore dust suppressant of the present invention

[0097] The preparation method is as follows:

[0098] A, 4.0 parts by weight of polyacrylamide water-soluble polymer material are dissolved with 180 parts by weight of water to obtain a solution;

[0099] B, in the described solution, add 2.0 parts by weight of styrene-butadiene latex;

[0100] C, then add 0.01 part by weight of mink oil amidopropylamine surfactant, stir to obtain iron ore dust suppressant of the present invention.

[0101]The viscosity of the iron ore dust suppressant was 23 mPa·S, the thickness of the solidified layer was 15 mm, and the hardness of the solidified layer was 34.8 kPa by using the methods described in this specification.

[0102] Using the method described in this specification, the iron ore dust suppression effect of the iron ore dust suppressant was measured, and the wind erosion rate was 0.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com