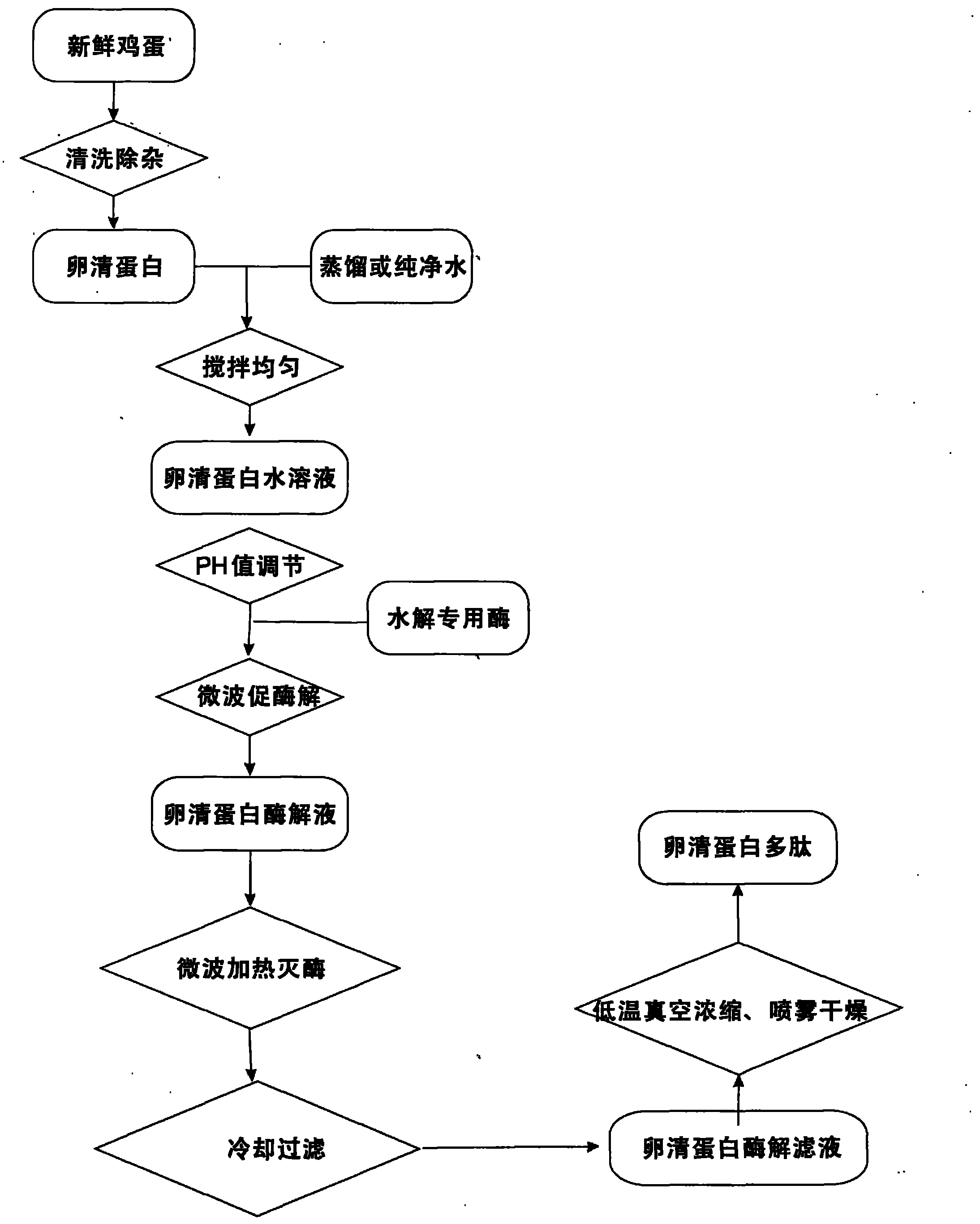

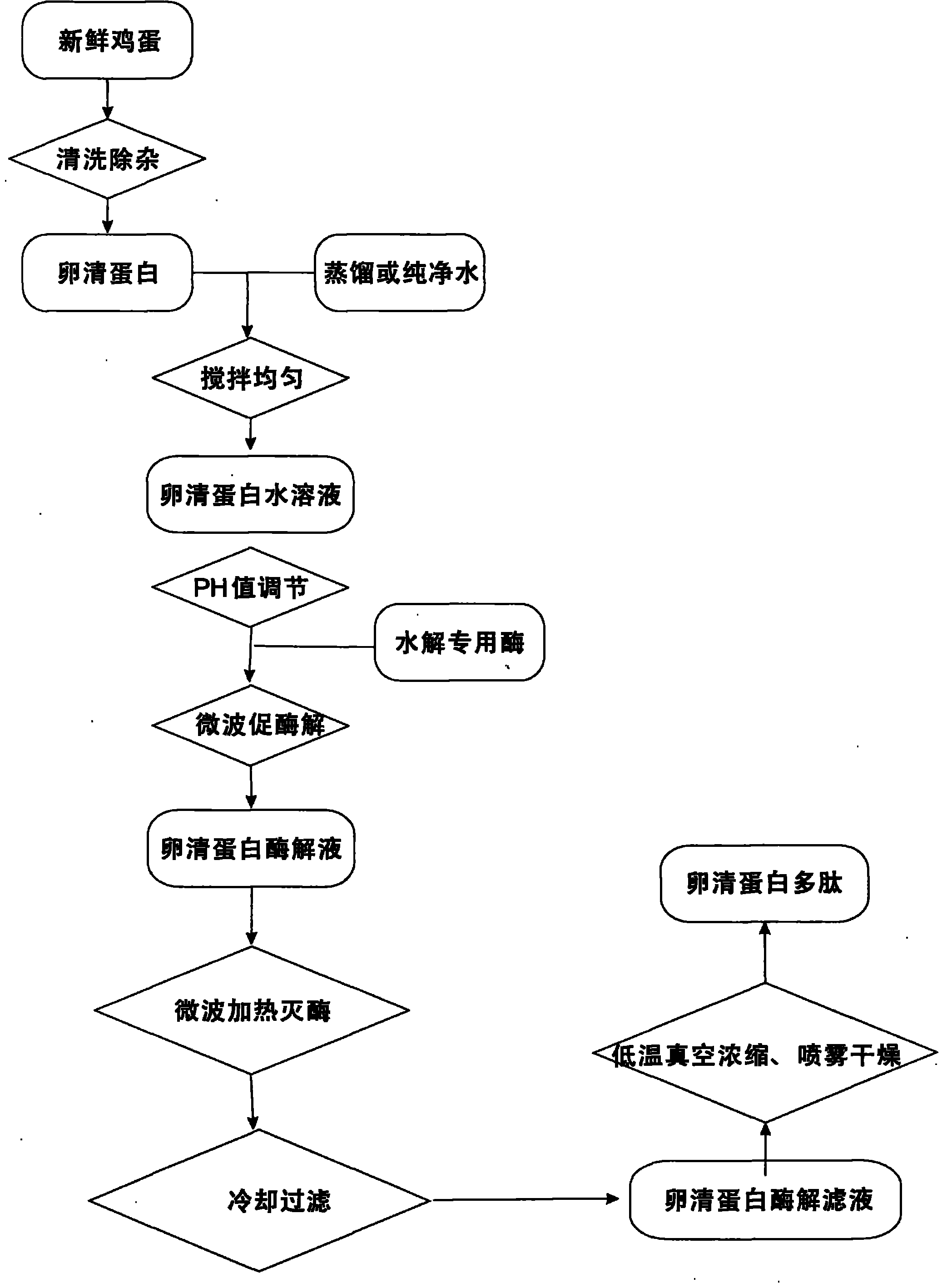

Method for preparing ovalbumin polypeptide by microwave-promoted enzymolysis

An ovalbumin and enzymatic hydrolysis technology is applied in the processing field of accelerated protein polypeptide hydrolysis, which can solve the problems of shortened reaction time, long relative cycle and high production cost, and achieves the effects of good product color, short reaction time and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the first step, weigh 1000g of ovalbumin, after pretreatment (remove egg yolk, eggshell), obtain ovalbumin; second step, after ovalbumin is homogenized, put into 5000ml microwave special reactor Add 2000ml of distilled water or pure water, stir well, adjust the pH value to 7.0 with potassium hydroxide, put it in the microwave equipment, turn on the microwave generator, power 100W, and the temperature rises to 50°C; the third step, press 1% of the weight of the egg white protein raw material, take the special enzyme for hydrolysis of egg white protein, add it to the obtained egg white protein aqueous solution, and turn on the microwave generator with a power of 100W, heat up to 50°C for enzymolysis, and microwave to accelerate the enzymolysis time Maintain for 30 minutes to obtain ovalbumin enzymatic hydrolyzate; in the fourth step, turn on the microwave generator 1000w and heat the obtained ovalbumin enzymatically to 100°C, keep it for 5 minutes to inactiva...

Embodiment 2

[0021] Embodiment 2: the first step, weigh 1500g of ovalbumin, after pretreatment (remove egg yolk, eggshell), obtain ovalbumin; second step, after ovalbumin is homogenized, put into 5000ml microwave special reactor Add 3000ml of distilled water or pure water, stir well, adjust the pH value to 7.5 with potassium hydroxide, put it in the microwave equipment, turn on the microwave generator, the power is 300W, and the temperature rises to 60°C; in the third step, press 1.5% of the weight of ovalbumin raw material, take the special enzyme for ovalbumin hydrolysis, add it to the obtained ovalbumin aqueous solution, and turn on the microwave generator with a power of 300W, heat up to 60°C for enzymolysis, and microwave to accelerate the enzymolysis time Maintain for 20 minutes to obtain ovalbumin enzymatic hydrolyzate; the fourth step is to turn on the microwave generator at 800w, microwave the obtained ovalbumin enzymatically to 100°C, keep it for 8 minutes to inactivate the enzyme...

Embodiment 3

[0022] Embodiment 3: the first step, weigh 2000g of ovalbumin, after pretreatment (remove egg yolk, eggshell), obtain ovalbumin; second step, after ovalbumin homogenate, put into 5000ml microwave special reactor Add 4000ml of distilled water or pure water, stir evenly, adjust the pH value to 8.0 with potassium hydroxide, put it in the microwave equipment, turn on the microwave generator, the power is 500W, and the temperature rises to 70°C; the third step, press 2.0% of the weight of ovalbumin raw material, take the special enzyme for ovalbumin hydrolysis, add it to the obtained ovalbumin aqueous solution, and turn on the microwave generator with a power of 500W, heat up to 70°C for enzymolysis, and microwave to accelerate the enzymolysis time Maintain for 15 minutes to obtain ovalbumin enzymatic hydrolyzate; in the fourth step, turn on the microwave generator at 500w and microwave the obtained ovalbumin enzymatically to 100°C, keep it for 10 minutes to inactivate the enzyme ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com