Method for comprehensively recovering various valuable metals from germanium-containing material by wet process

A technology for valuable metals and materials, which is applied in the field of wet comprehensive recovery of various valuable metals, can solve environmental pollution and other problems, and achieve the effects of environmental friendliness, simple operation process, and prevention of GeO loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

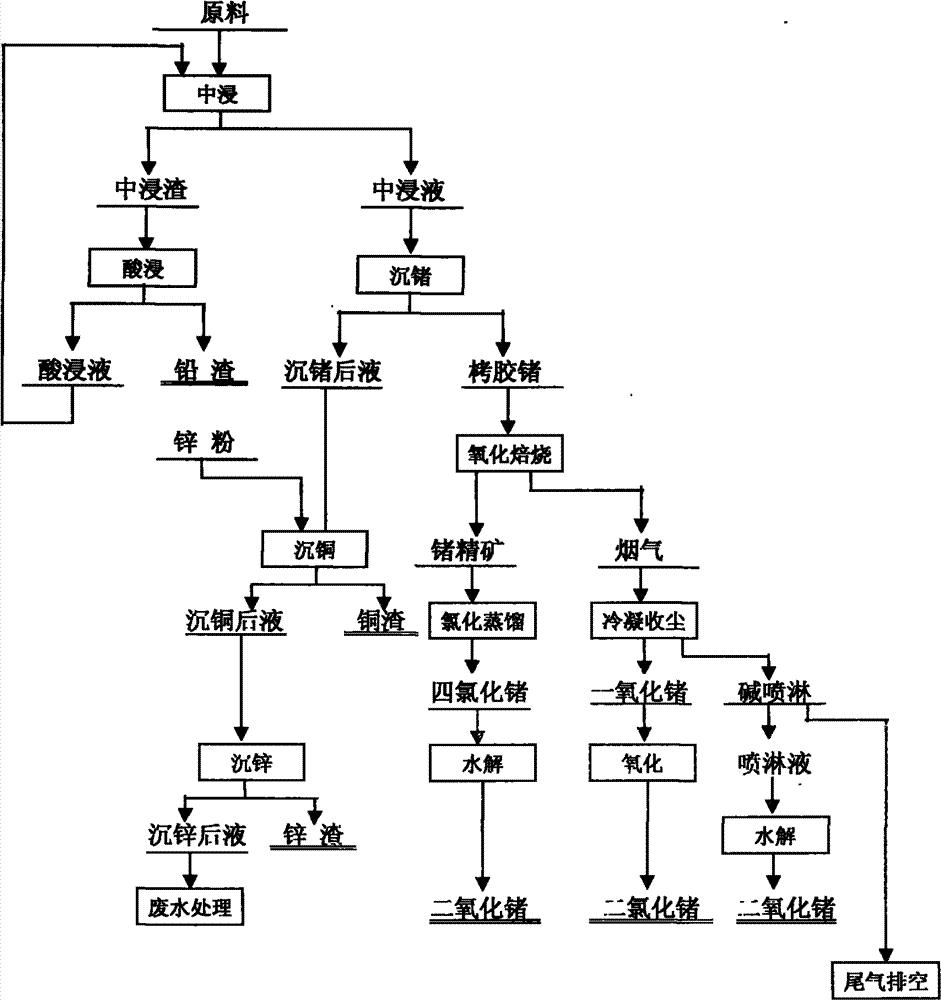

[0028] The approximate content of valuable metals in the materials we deal with is: Ge: 2.5kg / t, Cu: 6%, Zn: 24%, Pb: 33%, and the specific content of the experiment is: Ge: 2456g / t, Cu: 6.2%, Zn : 24.6%, Pb: 33.4% material 1kg for experiments; from the germanium-containing material wet comprehensive recovery of various valuable metals, the method includes leaching and separation of lead slag in the cycle, germanium tannin sinking to recover germanium dioxide, germanium sinking The process of recycling copper slag and zinc slag from waste liquid; the specific process flow is shown in the attached drawing:

[0029] 1) Dipping in circulation to separate lead slag

[0030] 1) a) Take 500g of material for medium acid leaching, mix germanium-containing material and sulfuric acid solution at a liquid-solid ratio of 3:1, mix and react for 1-3h, control the end point pH=2.5, and react at a temperature of 95°C; filter to obtain 245g of filter residue, medium 1500mL of immersion soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com