Cutting nozzle of cutting torch and processing method thereof

A processing method and technology of cutting nozzles, which are applied in combustion methods, lighting and heating equipment, gas fuel burners, etc., can solve the problems of insufficient combustion of preheated gas, unbalanced pressure, and slow cutting speed, so as to save oxygen, Easy to operate and guarantee the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

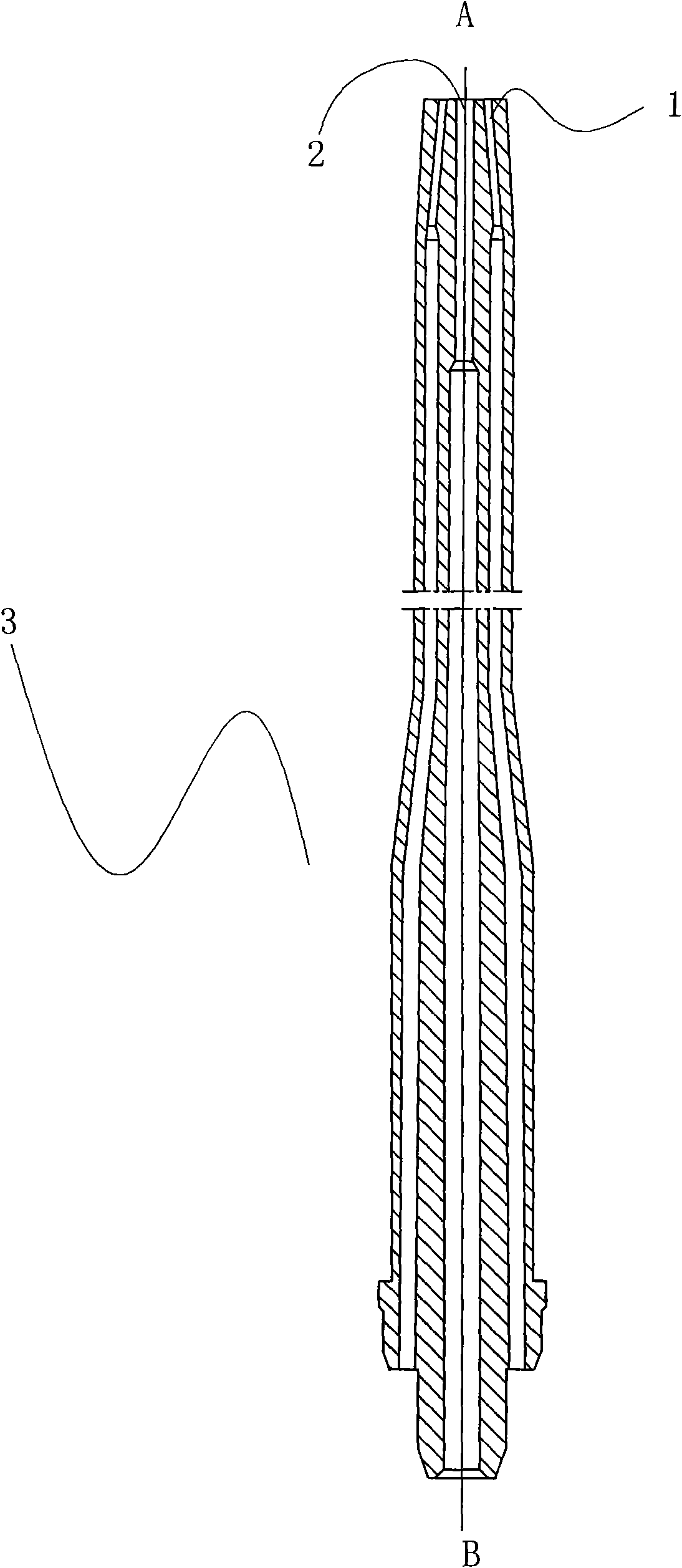

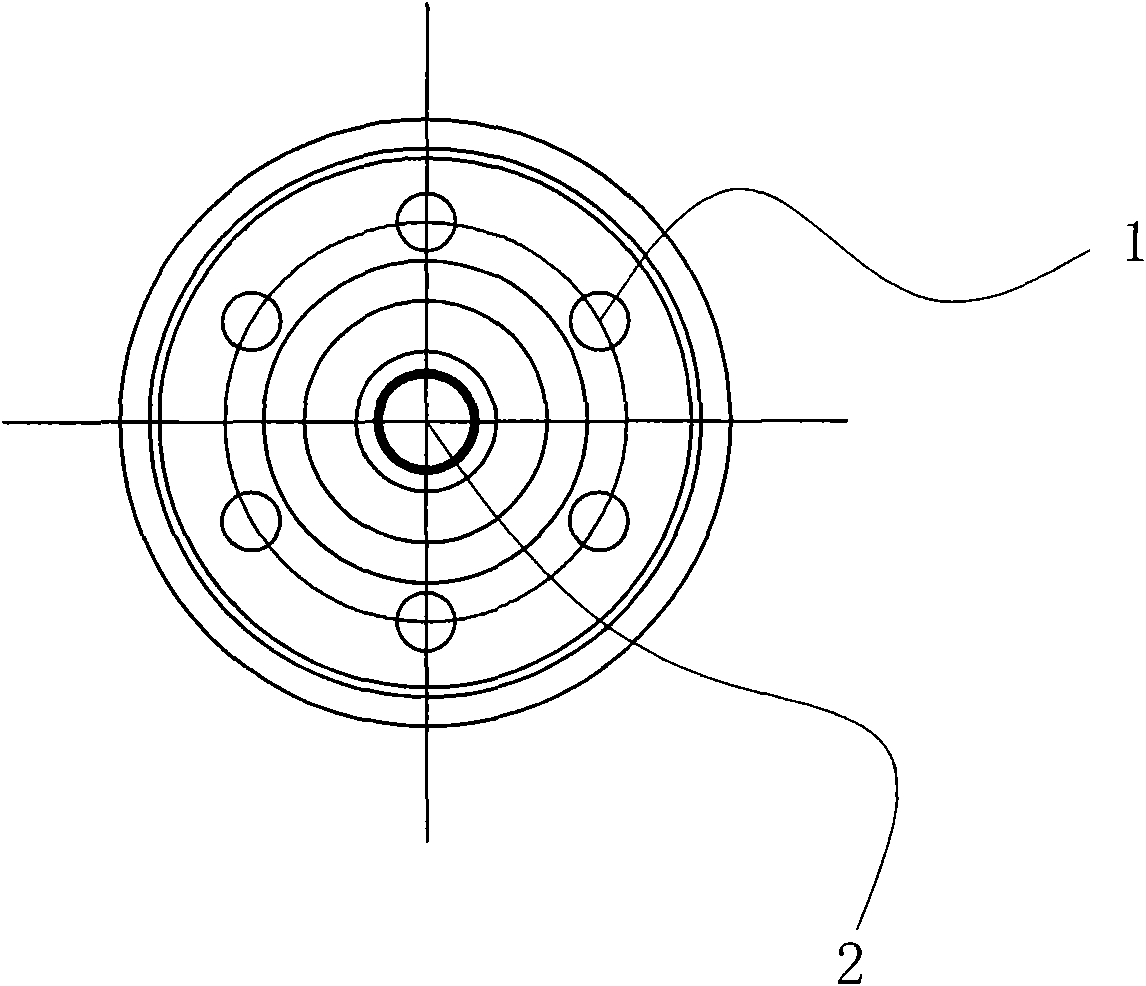

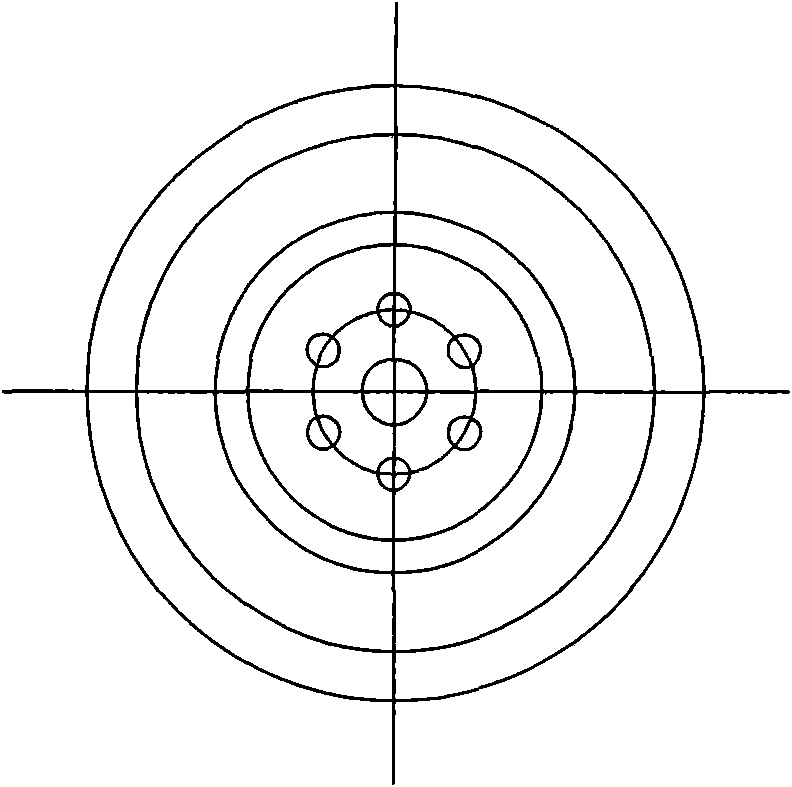

[0035] Such as Figure 1~3 Described a kind of cutting torch cutting nozzle, comprises preheating hole 1 and cutting hole 2, and this cutting nozzle body 3 is made of T 2 Made of copper, the total length of the cutting tip body 3 is 254 mm, which is convenient for deep cutting of the workpiece. The cutting hole and the preheating hole on the cutting tip body 3 are drilled by a drilling machine or a drilling machine or a lathe.

[0036] The processing method of the above-mentioned cutting torch cutting tip body 3 comprises the following steps as follows:

[0037] 1. Cutting;

[0038] 2. Chamfering of flat two end faces;

[0039] 3. Drill 6 preheating holes φ3mm;

[0040] 4. Wear steel wire;

[0041] 5. Forging 3 times to make the pressure of 6 preheated holes φ2mm

[0042] 6. Pull steel wire;

[0043] 7. Gold processing shape, drilling a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com