Optical engine for three-piece liquid crystal on silicon (LCOS) laser projection display

A laser projection and optical engine technology, applied in optics, optical components, instruments, etc., can solve the problems of complex structure and many devices, and achieve the effect of simple system structure, high brightness, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

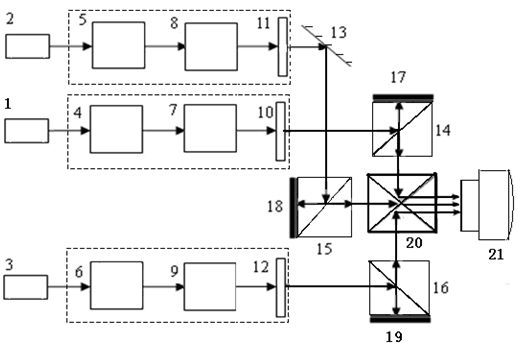

[0020] The three-chip LCOS laser projection display of the present invention uses an optical engine such as figure 1 As shown, it includes a red laser 1, a green laser 2, a blue laser 3, three uniform light shaping systems with the same optical structure, a mirror 13, a red polarization beamsplitter prism 14, a green polarization beamsplitter prism 15, and a blue polarization beamsplitter prism 16. Red LCOS 17, green LCOS 18, blue LCOS 19, X-type light combining prism 20 and projection objective lens 21. The wavelength of the red laser is 635 nm; the wavelength of the green laser is 532 nm; the wavelength of the blue laser is 447 nm; the mirror is a single-wavelength dielectric film high reflection mirror for reflecting green light. The three polarizing beam splitters are cubic prisms with a side length of 25.4mm, which have the functions of polarizing and analyzing at the same time; the X-type light combining prism is a cubic prism with a side length of 25.4mm, which can synt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com