Ultraviolet protective energy-saving lamp tube

A technology for energy-saving lamps and external protection, applied to parts of gas discharge lamps, etc., can solve problems such as unsatisfactory performance, and achieve the effects of reducing harm to people, low production costs, and good production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

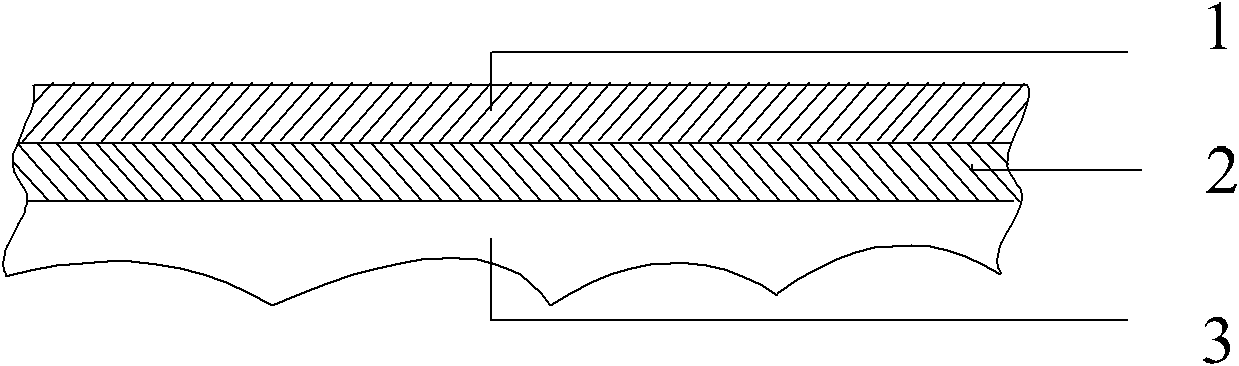

[0027] in such as Figure 5 The ZnO thin film was prepared on the clean spiral energy-saving lamp shown.

[0028] 1) configuration of zinc oxide thin film solution: 32g zinc acetate is dissolved in the mixed solution of 180ml ethylene glycol methyl ether and 10ml glacial acetic acid, then add 10ml and zinc acetate equimolar ethanolamine, obtain the solution that total volume is 200ml, in After 1.5h stirring at 80°C until the Zn + The concentration is 0.8mol / L to form a transparent and homogeneous solution;

[0029] 2) Cleaning of the lamp tube and removal of surface impurities (oil stains, impurity ions, etc.): Use deionized water with a resistivity of 16MΩ.cm and alcohol with a purity of more than 99% to ultrasonically, 3 to 4 times each, 3 minutes each time , followed by soaking in acetic acid solution with a concentration of 3% to 5% for 30s, and using high-purity N with a purity of 99.99% 2 blow dry;

[0030] 3) Throw glue to form a film: Pour the solution prepared in ...

Embodiment 2

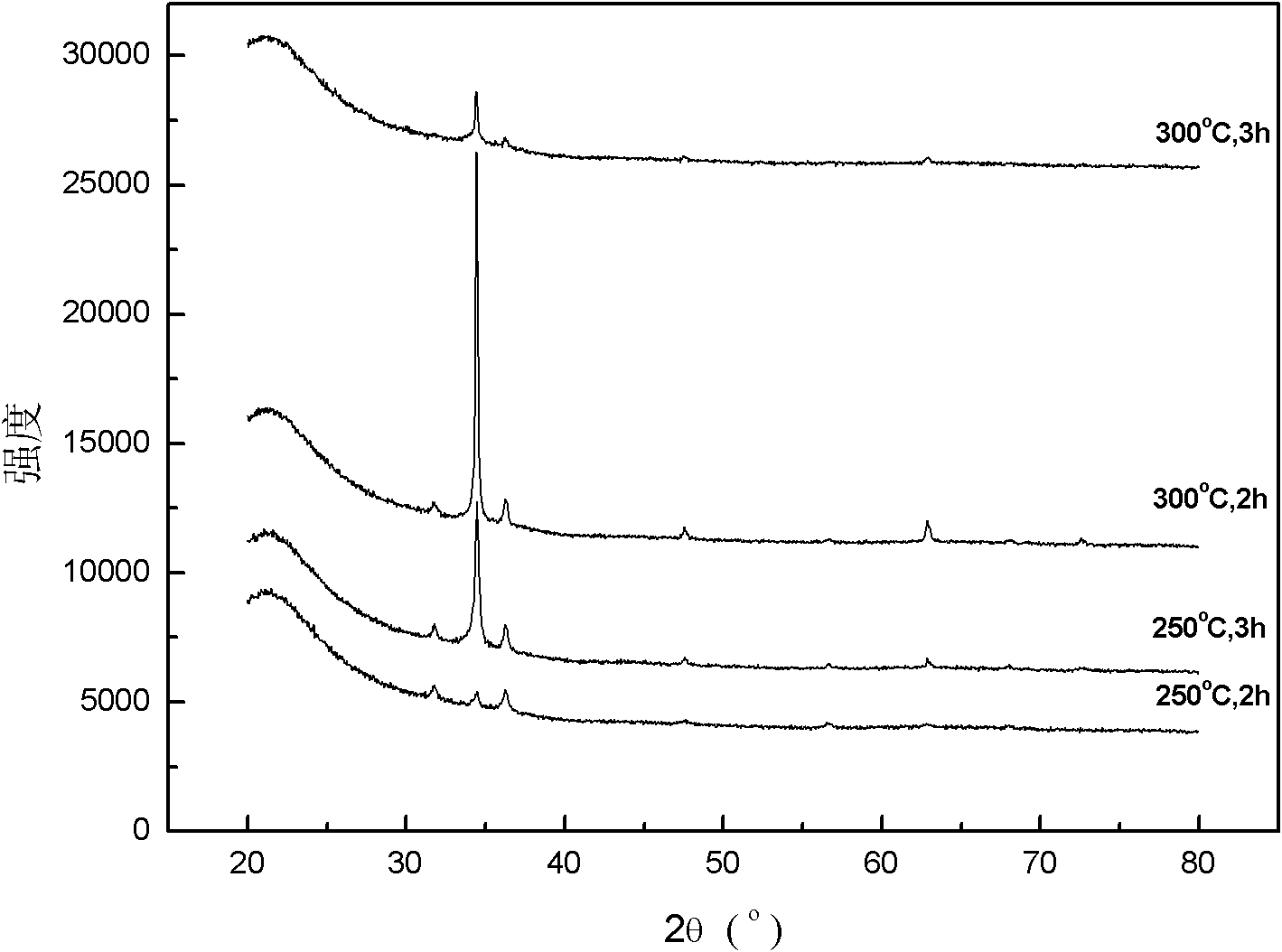

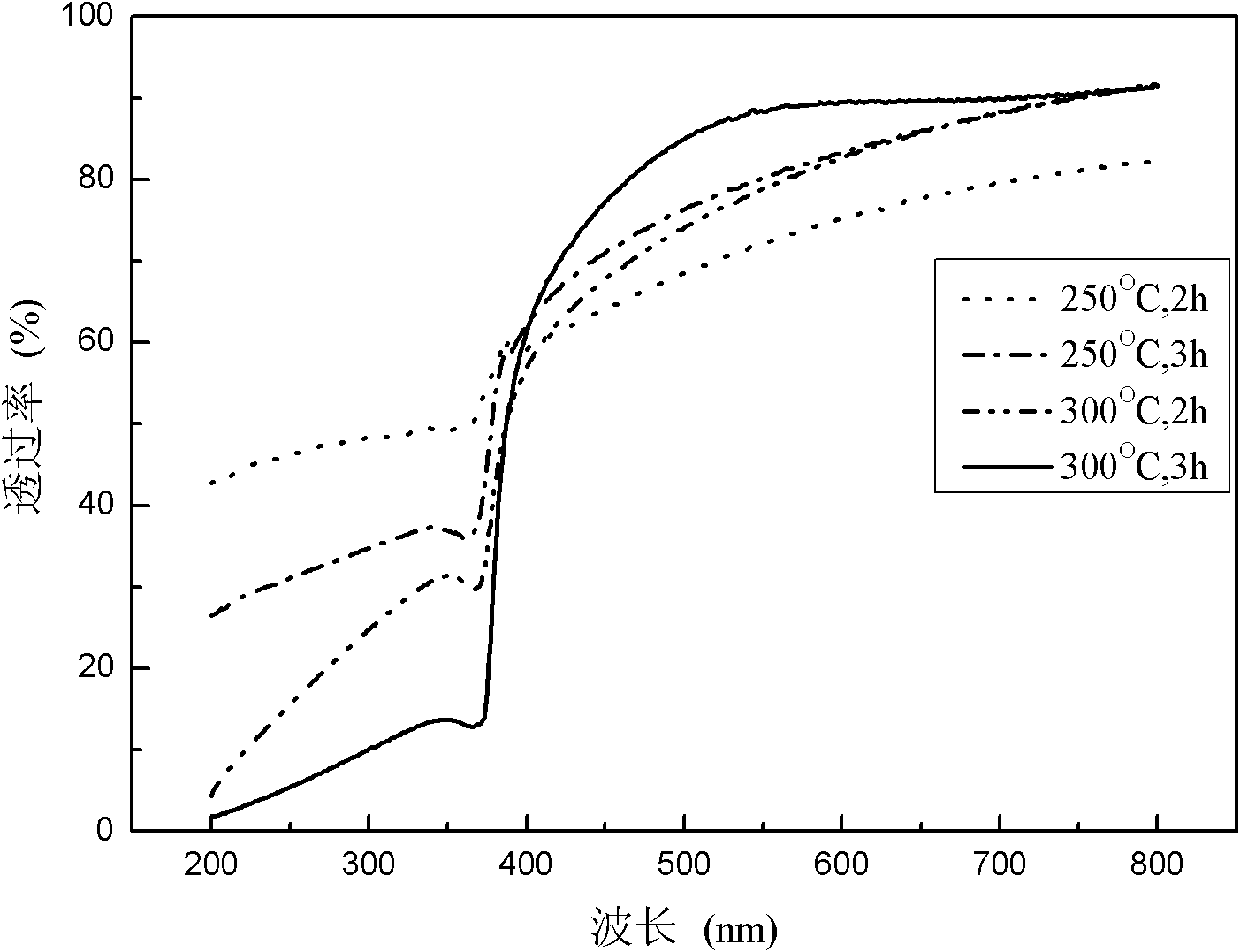

[0035] Steps 1) to 3) are the same as in Example 1, the heat treatment temperature in step 4) is 250° C., and the heat treatment time is 3 hours, and then phosphor coating is performed on the zinc oxide film.

Embodiment 3

[0037] Steps 1) to 3) are the same as in Example 1, the heat treatment temperature in step 4) is 300° C., the heat treatment time is 2 hours, and then phosphor coating is performed on the zinc oxide film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com