Two-stage three-phase photovoltaic grid-connected system without direct-current (DC) voltage sensor and control method of system

A technology of voltage sensor and control method, applied in the field of solar photovoltaic power generation, can solve the problems of increasing system volume, reducing system reliability, increasing construction cost, etc., and achieves the effect of simplifying configuration, improving system reliability, and saving construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

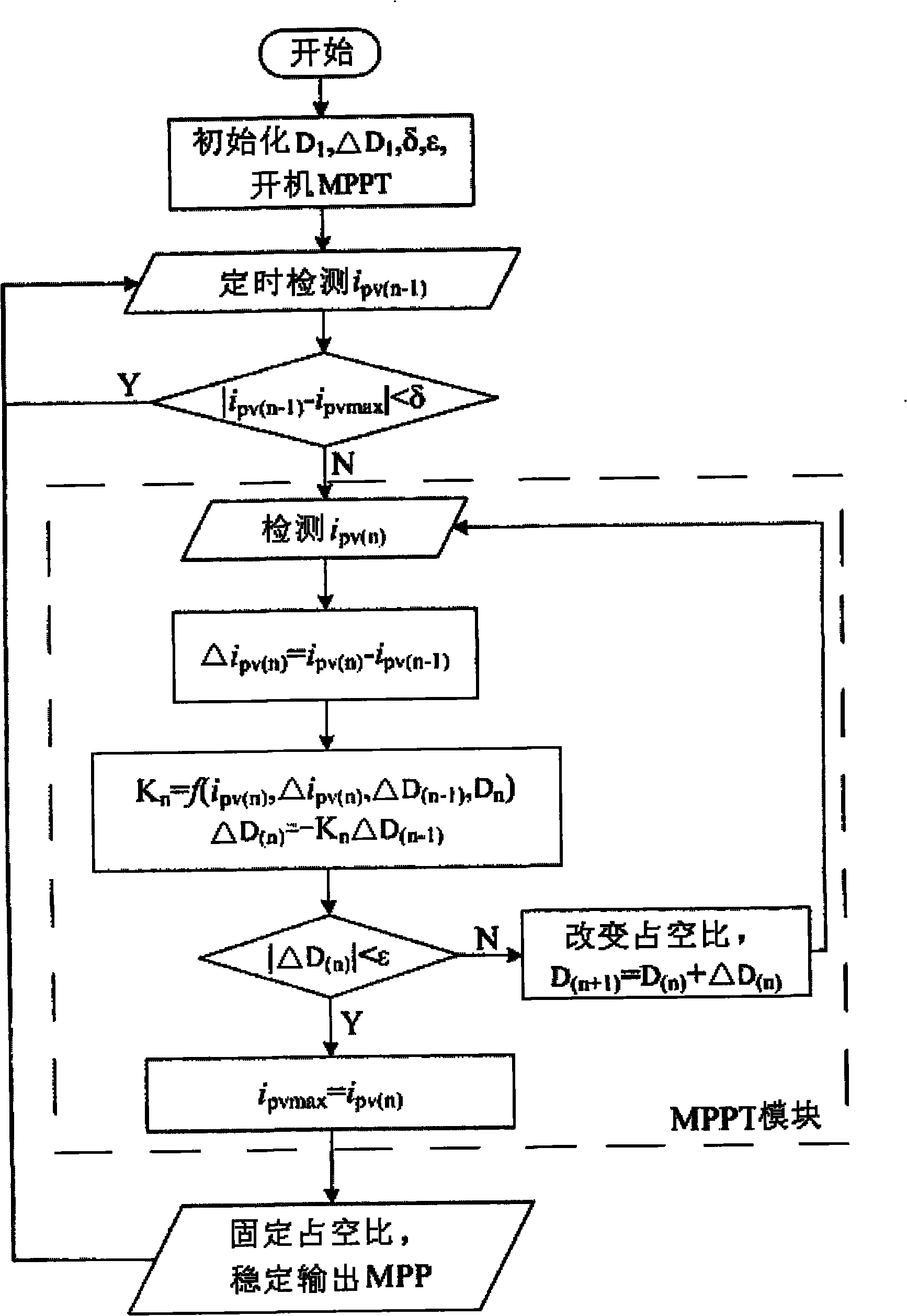

[0057] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

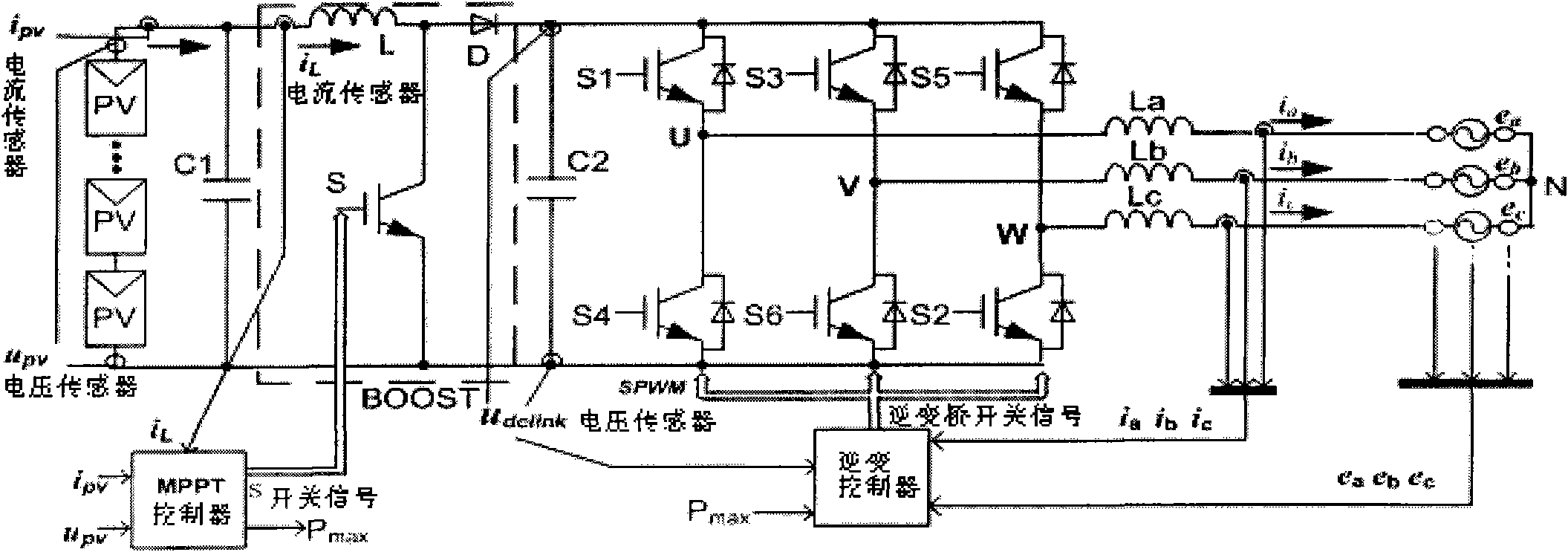

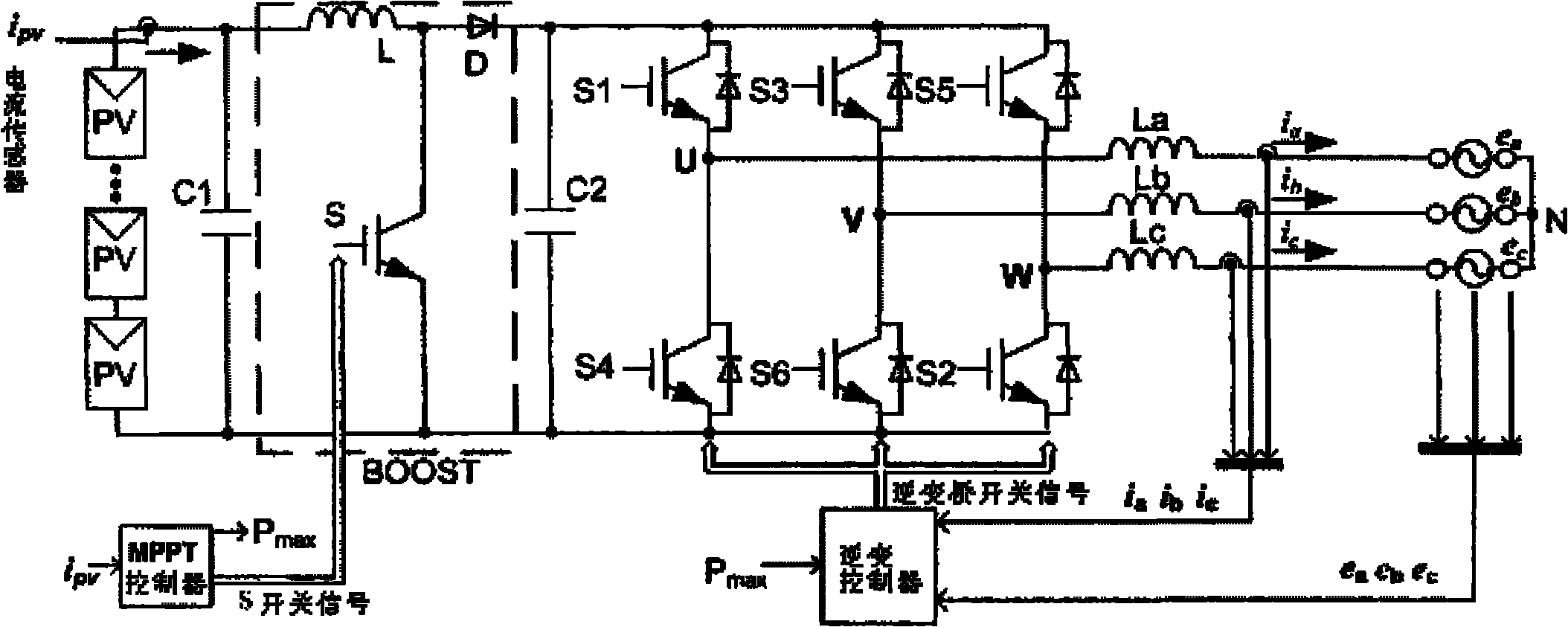

[0058] figure 2 The meaning of each symbol in is: e a 、e b 、e c is the phase voltage of the three-phase grid where the inverter is connected to the grid; i a i b i c is the three-phase grid-connected current of the photovoltaic system inverter; L a , L b , L c L is the filter inductor on the DC side; S1, S2, S3, S4, S5, and S6 are the switches of the three-phase inverter bridge, and the insulated gate transistor (IGBT) which can be turned off by parallel reverse diodes ); U, V, W are the three-phase output terminals of the grid-connected inverter; D is the Boost circuit diode; S is the Boost circuit switch tube; C 1 is the DC voltage stabilizing capacitor; C 2 is the DC link voltage stabilizing capacitor; PV is the photovoltaic panel array; i pv Output current for the photovoltaic panel array; P max The maximum power provided for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com