Double-fed brushless motor rotor and manufacturing method thereof

A brushless motor and rotor technology, used in the manufacture of stator/rotor bodies, electrical components, electromechanical devices, etc., can solve the problems of poor magnetic coupling performance, low magnetic field modulation ability, increased motor loss, etc., and achieve good rotational dynamic balance , Conducive to heat dissipation, enhance the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

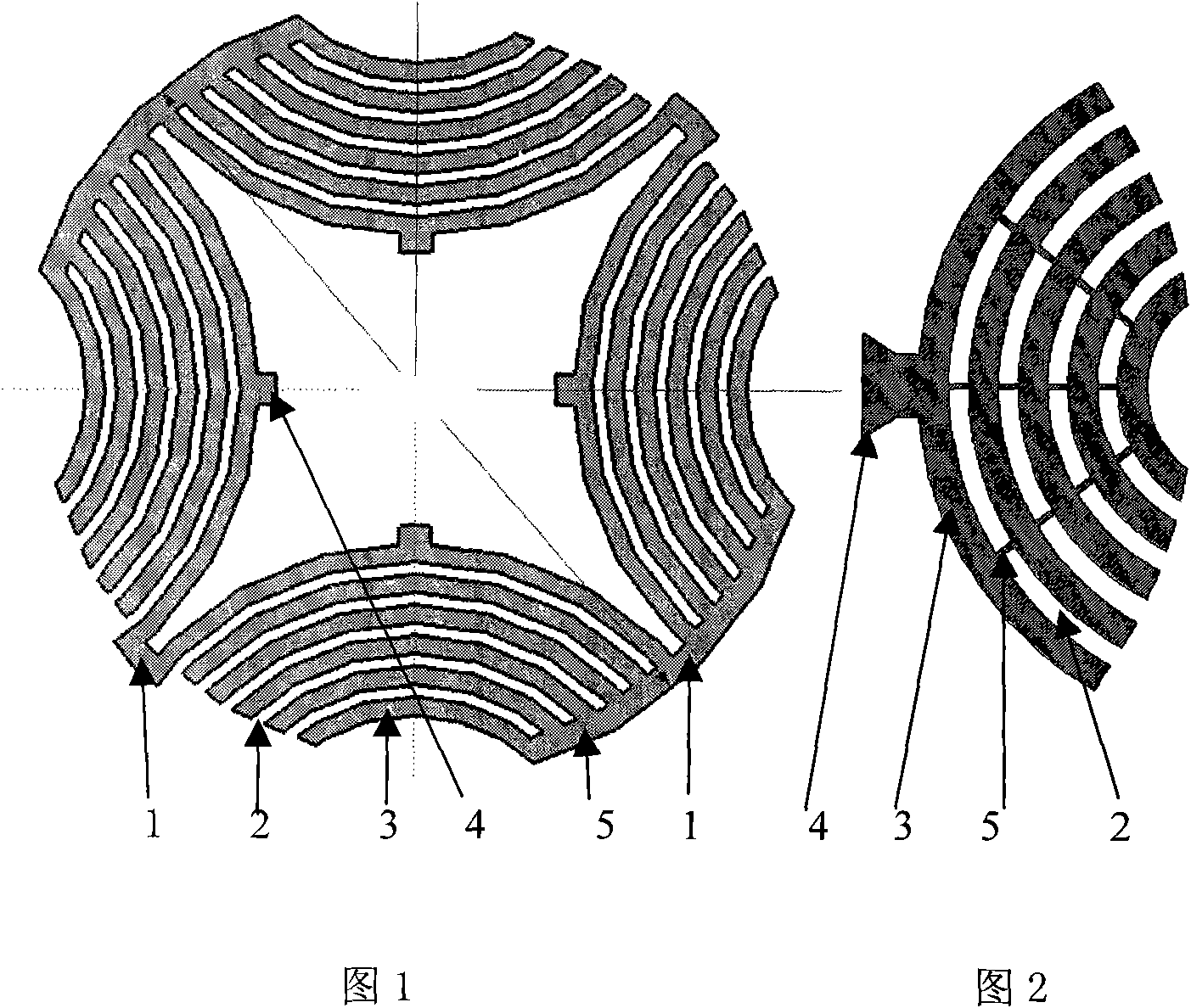

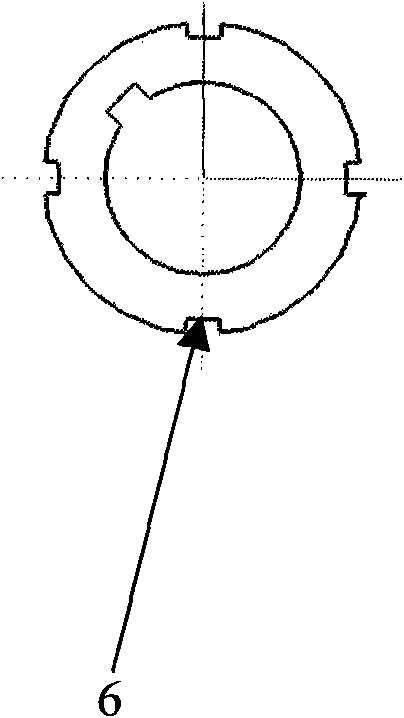

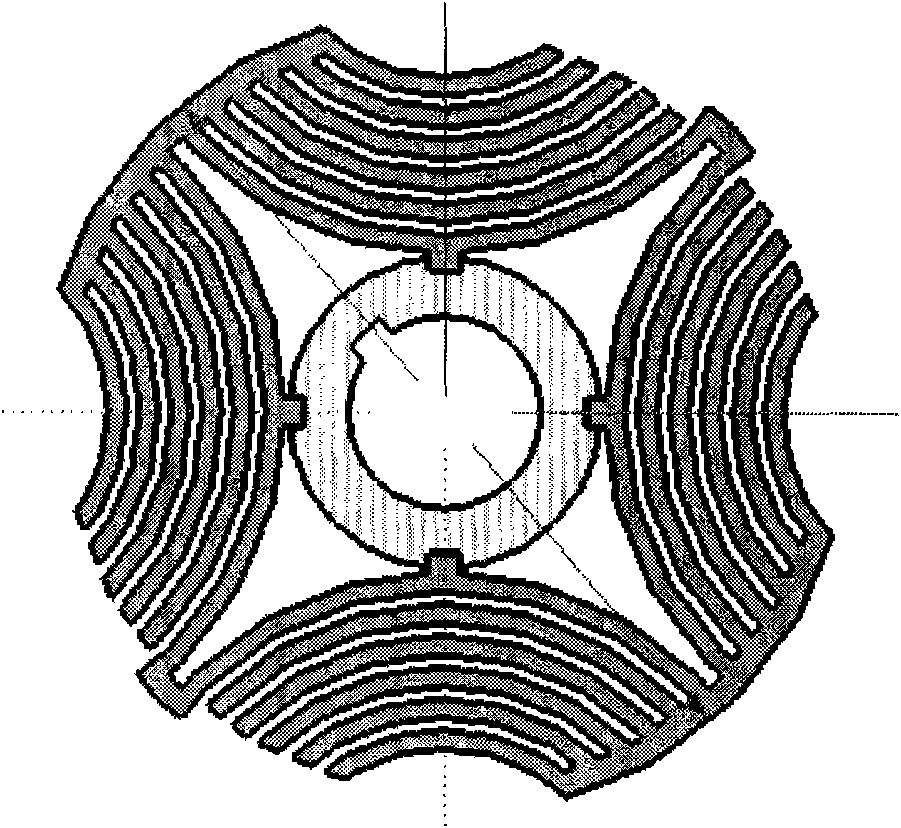

[0038] The present invention relates to the design and manufacture of a double-fed brushless motor rotor structure. For the convenience of explanation, the magnetic, electrical and mechanical characteristics and design requirements of the magnetic permeance module are described here.

[0039] 1 The characteristics and requirements of the magnetic permeability module in the magnetic circuit

[0040] The largest possible magnetic isolation is required between the rotor magnetic permeance modules, and each magnetic permeance module has no distinction between N and S polarities. Each magnetic permeance module is formed by alternately alternating multiple magnetic permeable layers and magnetic barrier layers. The function of adding a magnetic barrier layer is to limit the magnetic flux path in each permeable module, so that the permeance in a specific direction is maximized and the permeance in a perpendicular direction is minimized.

[0041] 2 Mechanical stress characteristics an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com