Method for preparing compound liquoric root tables

A technology of compound licorice tablets and licorice extract powder, applied to medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc., can solve the problems of cumbersome steps, low production capacity, and low efficiency, and achieve simplified process steps and high production efficiency Improve the effect of good efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

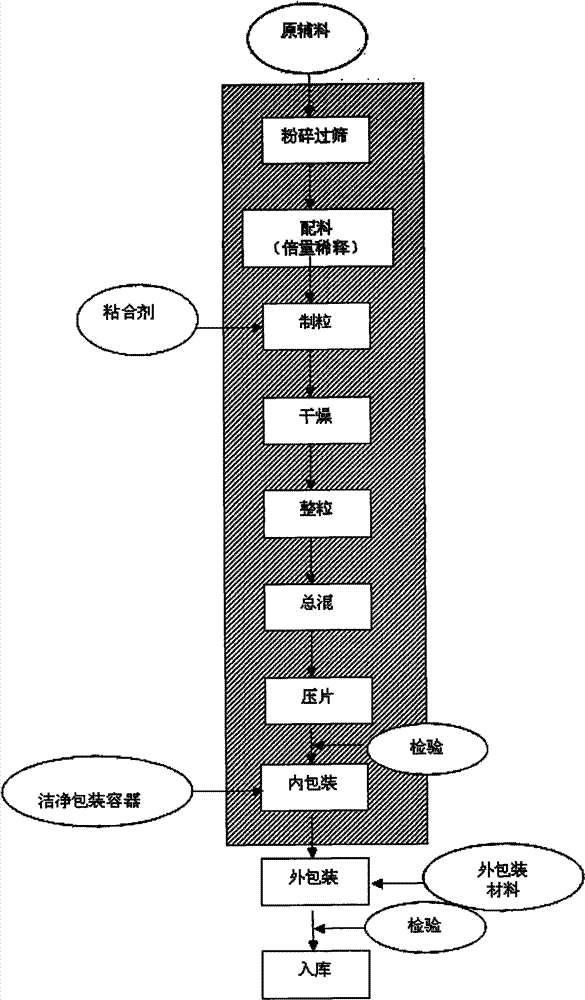

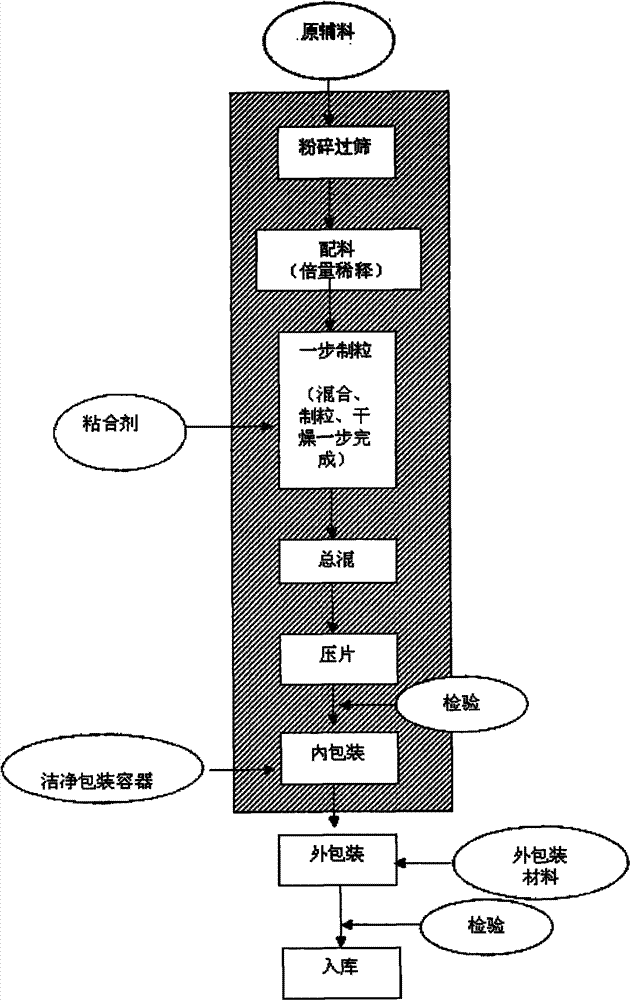

Method used

Image

Examples

Embodiment 1

[0016] Glycyrrhizae extract powder and sodium benzoate are passed through an 80-mesh sieve, and there is no foreign matter in the appearance after the sieve. 14kg poppy fruit extract powder was mixed with 10kg talcum powder, 20kg licorice extract powder, and 7kg sodium benzoate in a three-dimensional motion mixer with a motor speed of 800 rpm for 10 minutes to obtain mixture A. 51kg of mixture A was mixed with 100kg of licorice extract powder and 10kg of talcum powder in a three-dimensional motion mixer with a motor speed of 800 rpm for 10 minutes to obtain mixture B. 161 kg of mixture B was mixed with 273.75 kg of licorice extract powder and 23.75 kg of talcum powder in a three-dimensional motion mixer with a motor speed of 600 rpm for 40 minutes to obtain mixture C. Dissolve 7kg star anise oil and 7kg camphor in 42.217kg 95% ethanol to make adhesive.

[0017] Put the mixture C in a spray drying granulator, spray the binder into the tank under the pressure of 0.5MPa, set the...

Embodiment 2

[0019] Glycyrrhizae extract powder and sodium benzoate are passed through an 80-mesh sieve, and there is no foreign matter in the appearance after the sieve. 14kg poppy fruit extract powder was mixed with 10kg talcum powder, 20kg licorice extract powder, and 7kg sodium benzoate in a three-dimensional motion mixer with a motor speed of 800 rpm for 10 minutes to obtain mixture A. 51kg of mixture A was mixed with 100kg of licorice extract powder and 10kg of talcum powder in a three-dimensional motion mixer with a motor speed of 800 rpm for 10 minutes to obtain mixture B. 161 kg of mixture B was mixed with 273.75 kg of licorice extract powder and 23.75 kg of talcum powder in a three-dimensional motion mixer with a motor speed of 600 rpm for 40 minutes to obtain mixture C. Dissolve 7kg star anise oil and 7kg camphor in 42.217kg 95% ethanol to make adhesive.

[0020] Put the mixture C in a spray drying granulator, spray the binder into the tank under the pressure of 0.5MPa, set the...

Embodiment 3

[0022] Glycyrrhizae extract powder and sodium benzoate are passed through an 80-mesh sieve, and there is no foreign matter in the appearance after the sieve. 14kg poppy fruit extract powder was mixed with 10kg talcum powder, 20kg licorice extract powder, and 7kg sodium benzoate in a three-dimensional motion mixer with a motor speed of 800 rpm for 10 minutes to obtain mixture A. 51kg of mixture A was mixed with 100kg of licorice extract powder and 10kg of talcum powder in a three-dimensional motion mixer with a motor speed of 800 rpm for 10 minutes to obtain mixture B. 161 kg of mixture B was mixed with 273.75 kg of licorice extract powder and 23.75 kg of talcum powder in a three-dimensional motion mixer with a motor speed of 600 rpm for 40 minutes to obtain mixture C. Dissolve 7kg star anise oil and 7kg camphor in 42.217kg 95% ethanol to make adhesive.

[0023] Put the mixture C in a spray drying granulator, spray the binder into the tank under the pressure of 0.5MPa, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com