Method for preparing AlPO4-9 aluminium phosphate molecular sieve

A technology of aluminum phosphate molecular sieve and synthesis method, applied in the direction of molecular sieve characteristic aluminum phosphate, molecular sieve and alkali-exchanged phosphate, phosphorus compound, etc., can solve problems such as unreported crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Example 1, at first prepare the piperazine solution of 0.434 mol / liter. In a 100ml beaker, mix 2ml of ethylene glycol with 15ml of piperazine solution, stir for 10 minutes, add 1.702g of aluminum isopropoxide, stir for another 30 minutes, then add 1.14ml of 85% H 3 PO 4 , after stirring for 1 hour, a homogeneous mixture was formed, and then transferred to a stainless steel reactor with a polytetrafluoroethylene liner, crystallized at 180 ° C for 5 days to obtain colorless transparent crystals, washed with distilled water and suction filtered, in The target product was obtained after drying at room temperature. The product was characterized using the following instruments and methods:

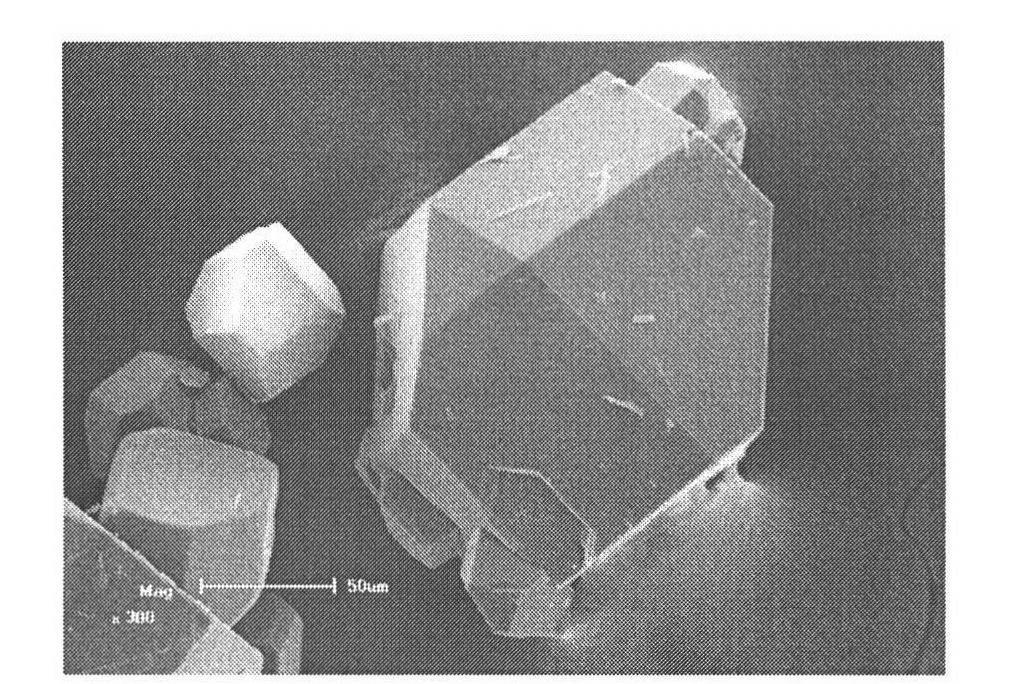

[0016] 1. Use the SHIMADZU SS-550 scanning electron microscope to obtain the morphology of the crystal ( figure 1 )

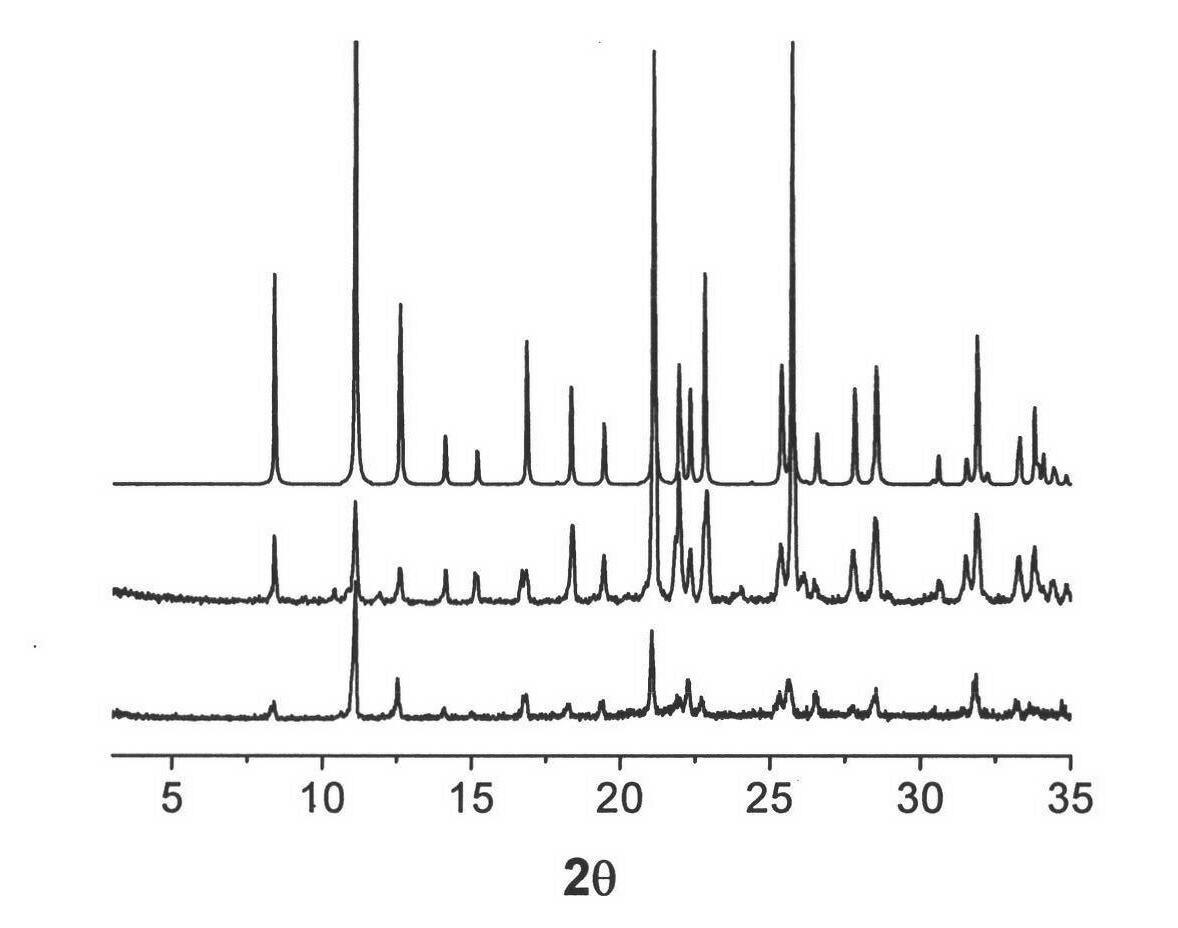

[0017] 2, use Bruker-D8 type X-ray diffractometer to measure the X-ray powder diffraction spectrum of product, obtain the XRD figure of product ( figure 2 ).

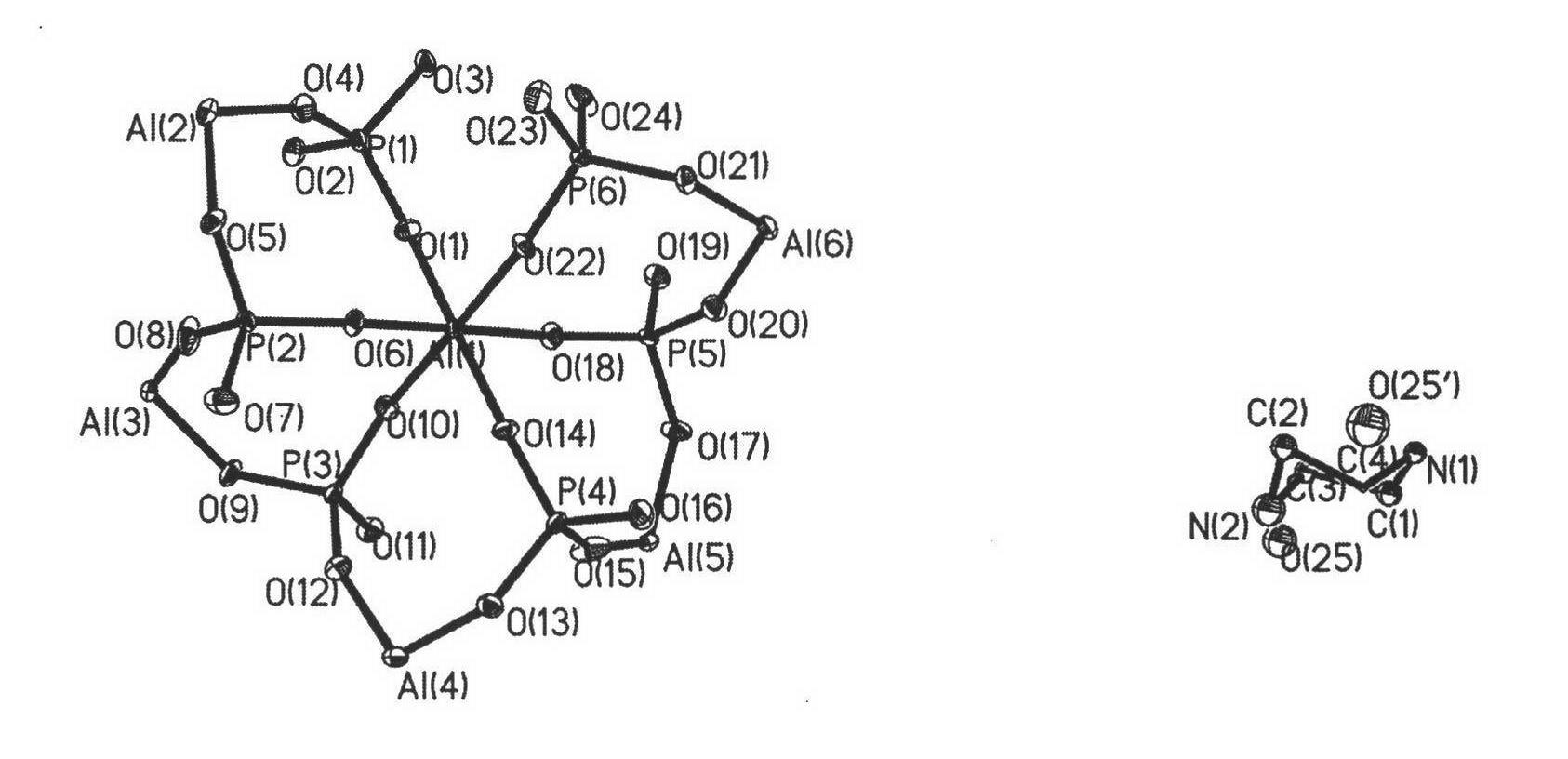

[001...

example 2

[0027] Example 2, at first prepare the piperazine solution of 0.434 mol / liter. In a 100ml beaker, mix 2ml of ethylene glycol with 15ml of piperazine solution, stir for 10 minutes, add 1.702g of aluminum isopropoxide, stir for another 30 minutes, then add 1.14ml of 85% H 3 PO 4 , after stirring for 1 hour, a homogeneous mixture was formed, and then transferred to a stainless steel reactor with a polytetrafluoroethylene liner, crystallized at 170 ° C for 5 days to obtain colorless transparent crystals, washed with distilled water and suction filtered, in The target product was obtained after drying at room temperature. Every characterization and result are identical with example 1.

example 3

[0028] Example 3, at first prepare the piperazine solution of 0.451 mol / liter. In a 100ml beaker, mix 2ml of ethylene glycol with 15ml of piperazine solution, stir for 10 minutes, add 1.702g of aluminum isopropoxide, stir for another 30 minutes, then add 1.14ml of 85% H 3 PO 4 After stirring for 1 hour, a homogeneous mixture was formed, and then transferred to a stainless steel reactor with a polytetrafluoroethylene liner, and crystallized at 180°C for 9 days to obtain colorless transparent crystals, which were washed with distilled water and suction filtered. The target product was obtained after drying at room temperature. Every characterization and result are identical with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com