Preparation method of low-carbon light reflecting energy-saving coating

A technology of energy-saving coatings and reflective light, which is applied in the direction of reflection/signal coatings, coatings, fibrous fillers, etc., can solve the problems of few types, affecting the film-forming characteristics and comprehensive mechanical properties of coatings, and achieve low cost and compatibility The effect of increasing and reducing the VOC content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

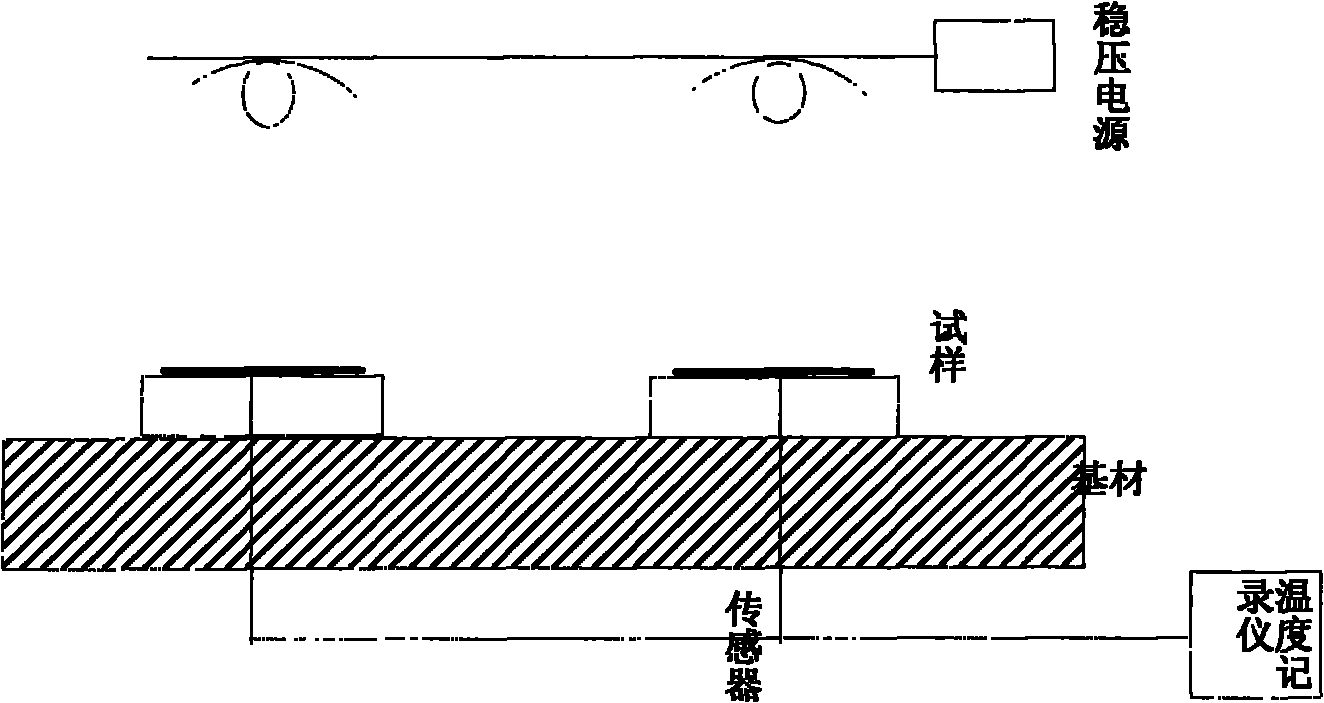

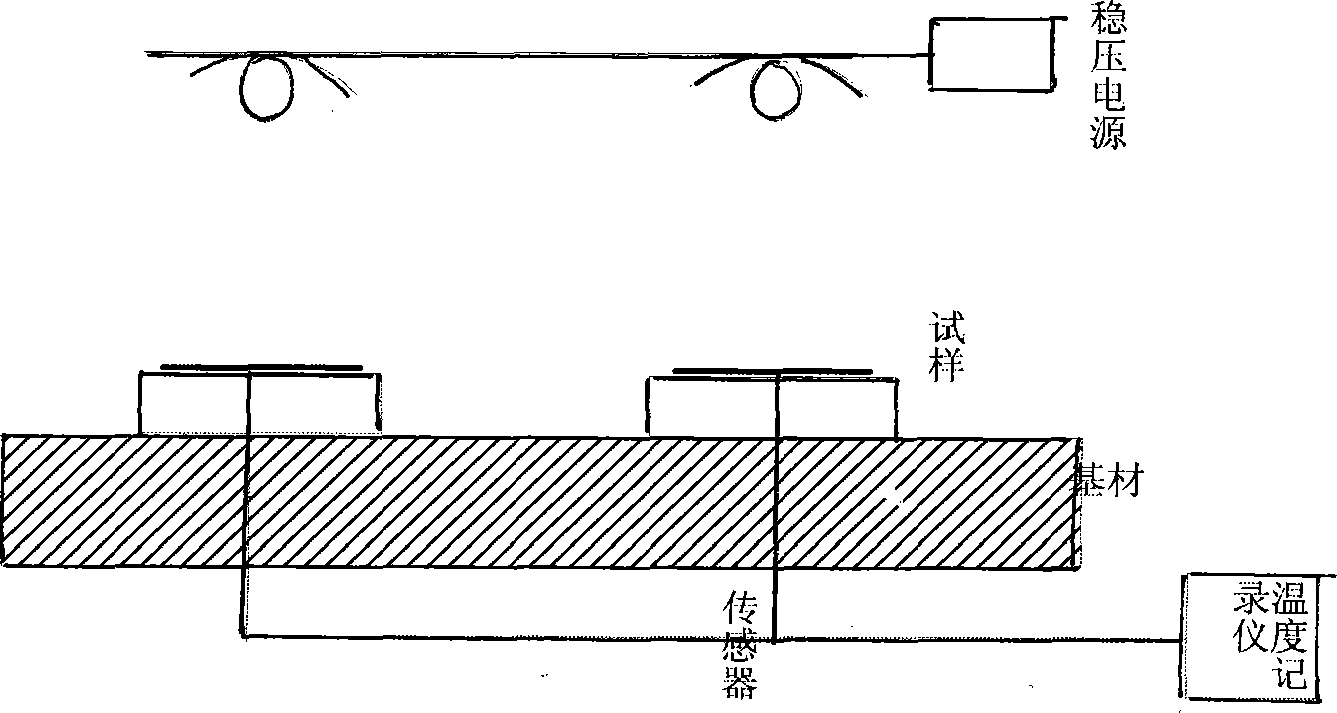

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in detail below through specific examples.

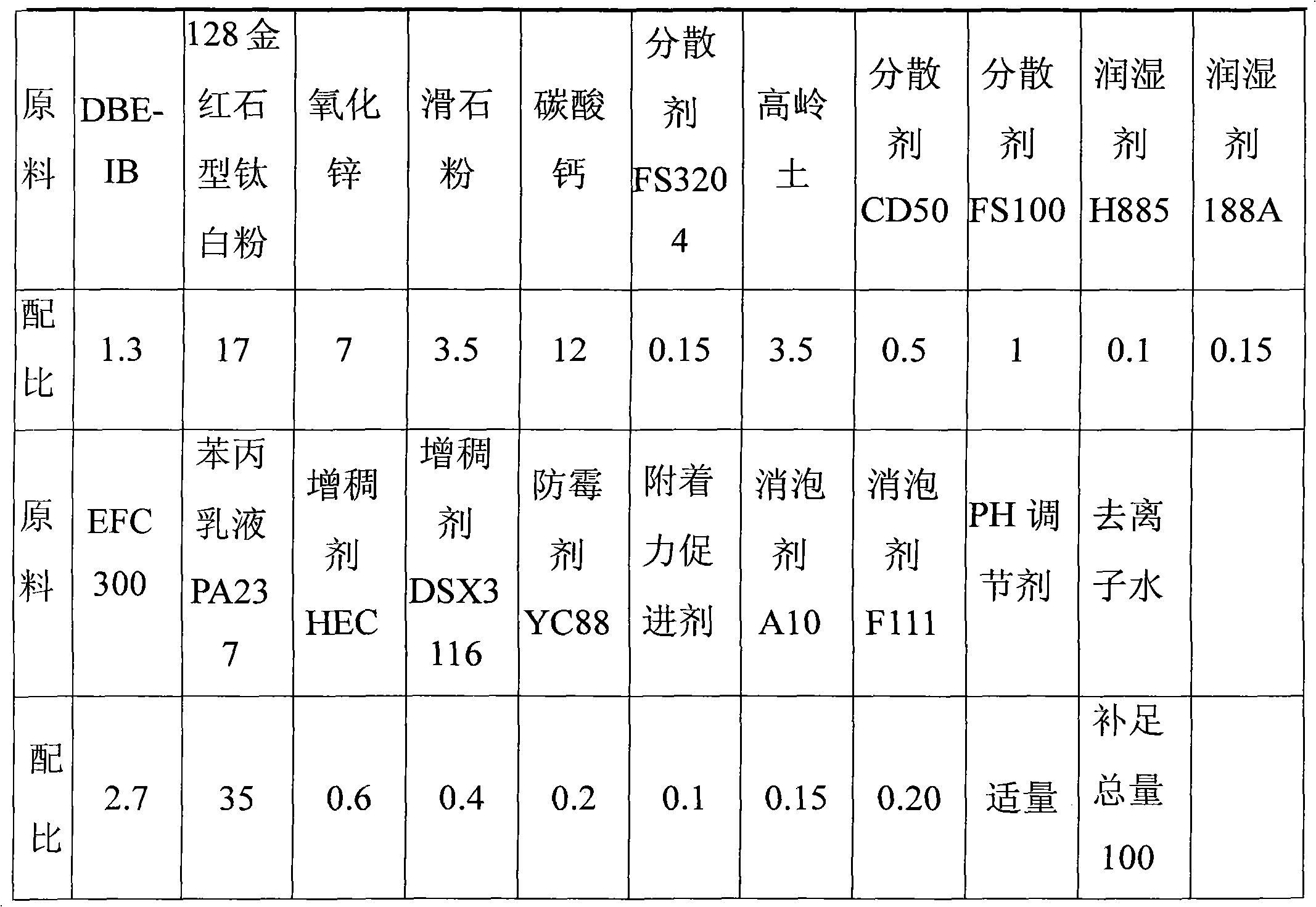

[0030] The paint of the present invention is prepared by adding various additives and water after modification of titanium dioxide, zinc oxide, talcum powder, kaolin and calcium carbonate pigments and fillers, and then adding emulsion. The composition of various pigments, fillers, additives and emulsions The proportioning is shown in Table 1, and according to the proportioning in Table 1, taking the preparation of 76Kg coating as an example (removing loss), the specific preparation steps are as follows:

[0031] The first step: preparation of modified pigments and fillers

[0032] Modification of titanium dioxide: First, stir 0.26Kg of titanate coupling agent KR-201 and 0.52Kg of isopropanol in a beaker at a low speed (250r / min), and then transfer them into a spherical funnel (the bottom end is made of nylon wire Net seal), then put 17Kg of titanium dioxide in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com