Lignite upgrading furnace

A technology for upgrading furnaces and lignite, which is applied in coking ovens, special forms of dry distillation, petroleum industry, etc., and can solve the problems of requiring moving mechanisms, complex structures, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

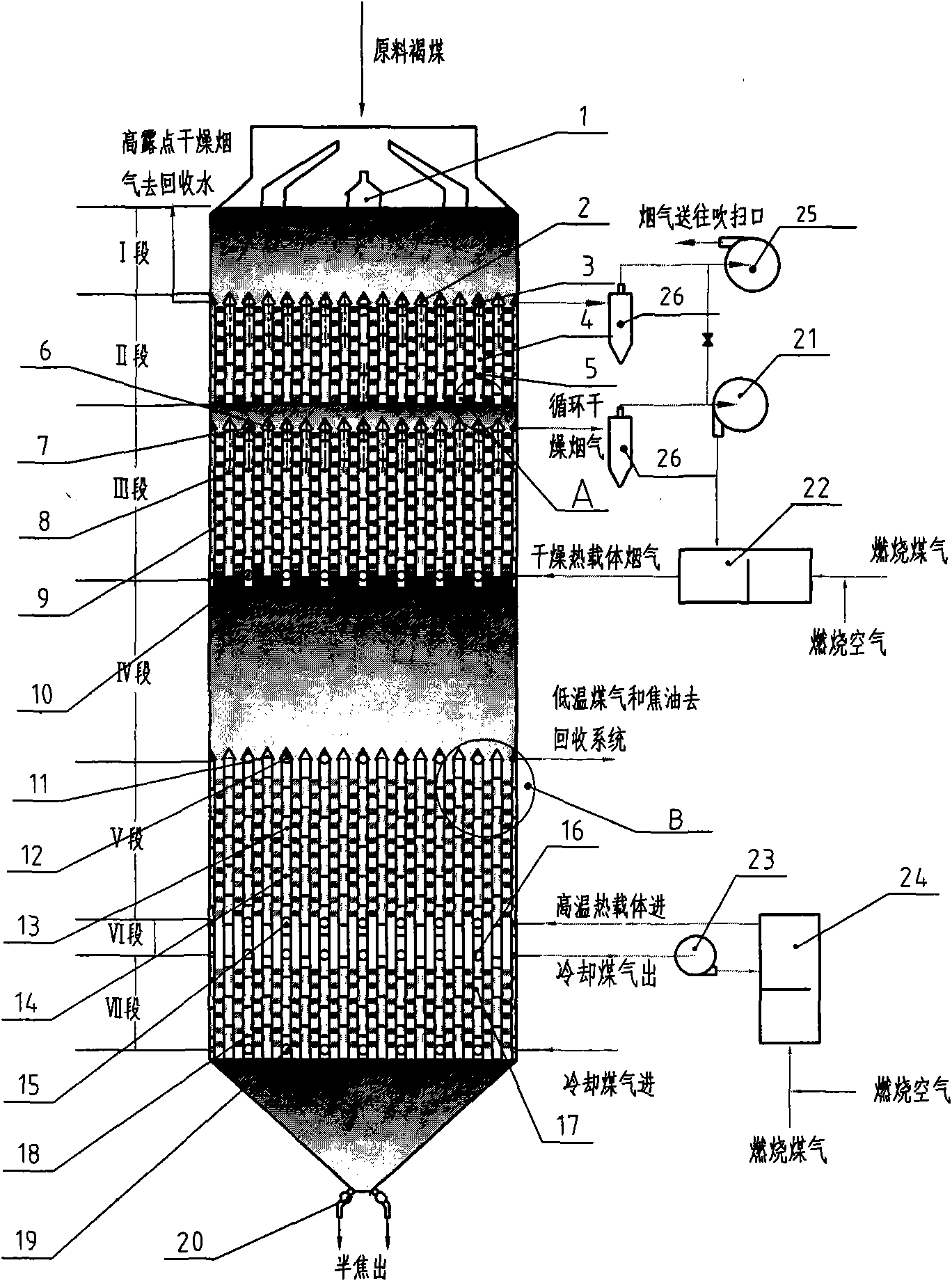

[0035] see figure 1 . Add the sieved raw lignite from the top of the furnace, spread it evenly through the distributor 1, and rely on the coke unloading machine at the bottom of the furnace to continuously discharge the finished product and automatically move downwards under the action of gravity to the coal seal section 1 of section I. The function is to ensure that the air does not flow back into the furnace, which may cause fire or explosion. For this reason, the dry smoke should be under a slight positive pressure on the surface of the coal seam.

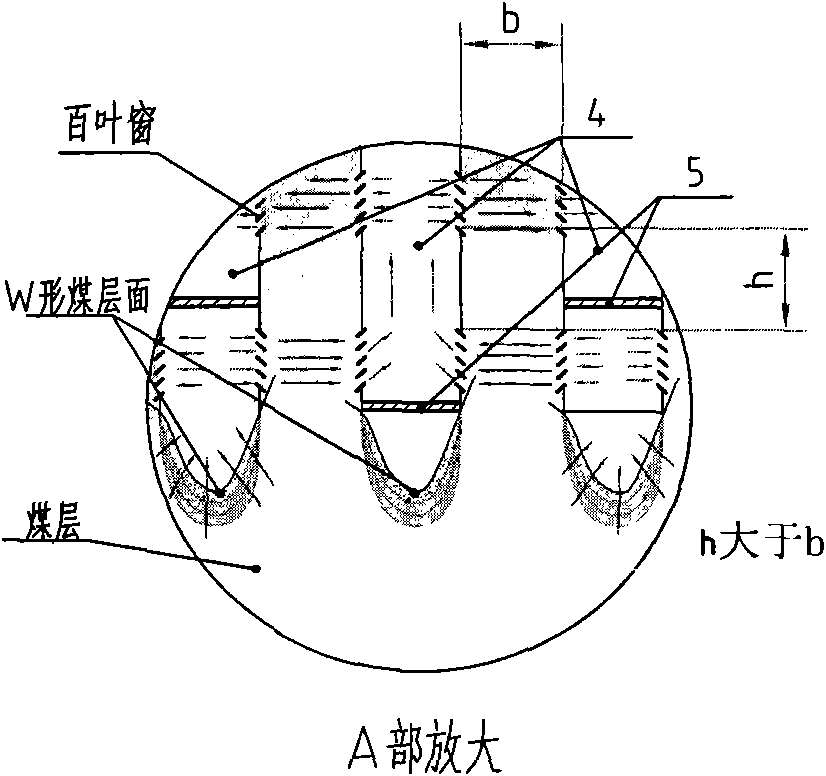

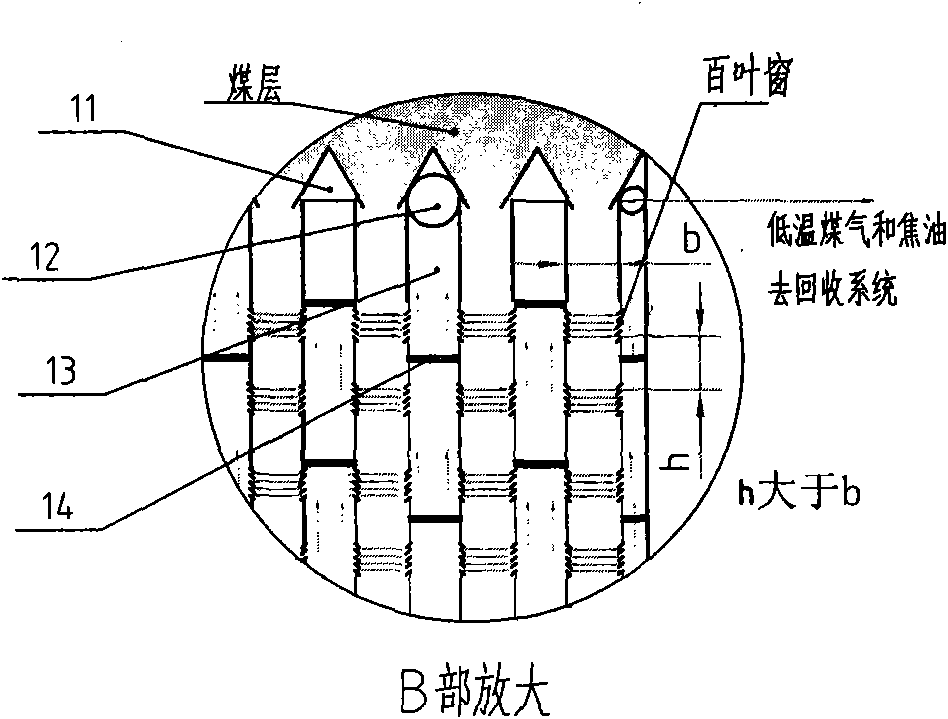

[0036] Section II is the pre-drying section. There is a row of outer row of dry flue gas collectors 2 on the top of this section. Under these cloths, the furnace charge surface is in a multiple W shape. Outer exhaust, the dew point of the outer exhaust flue gas is very high, and it should be recycled in some areas with severe water shortage. The Chinese Patent No. 2010101519277 of "A Method for Recovering Water from High Dew P...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap