Nozzle structure used in internal-combustion motor tail gas treatment device

A technology for exhaust gas treatment and internal combustion engine, which is applied to exhaust devices, mufflers, mechanical equipment, etc., can solve the problems of uncommon application of diesel engine post-processors, expensive manufacturing and use costs, and complex hardware structures, achieving superior performance and reducing manufacturing costs. The effect of using cost and simple hardware structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

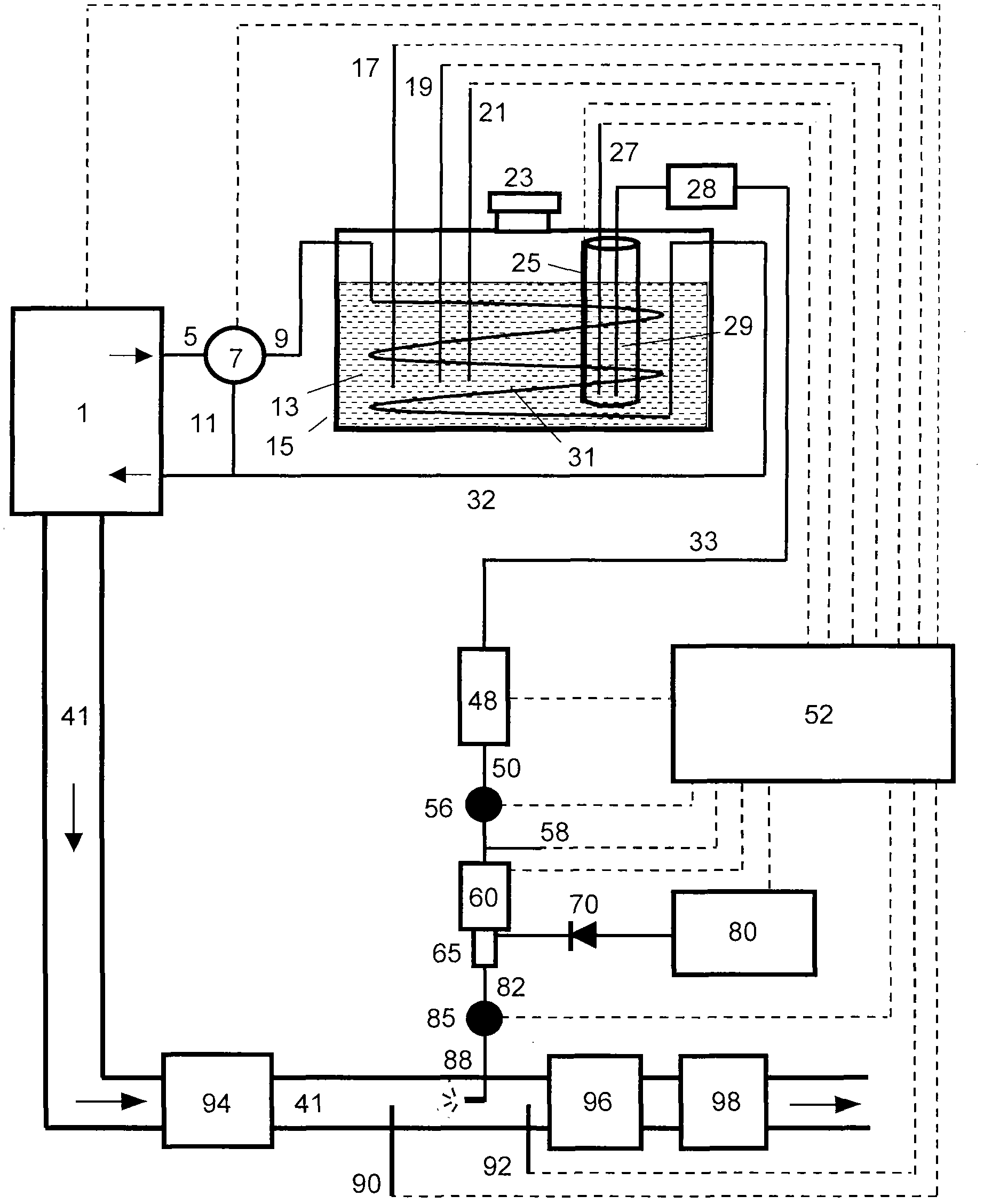

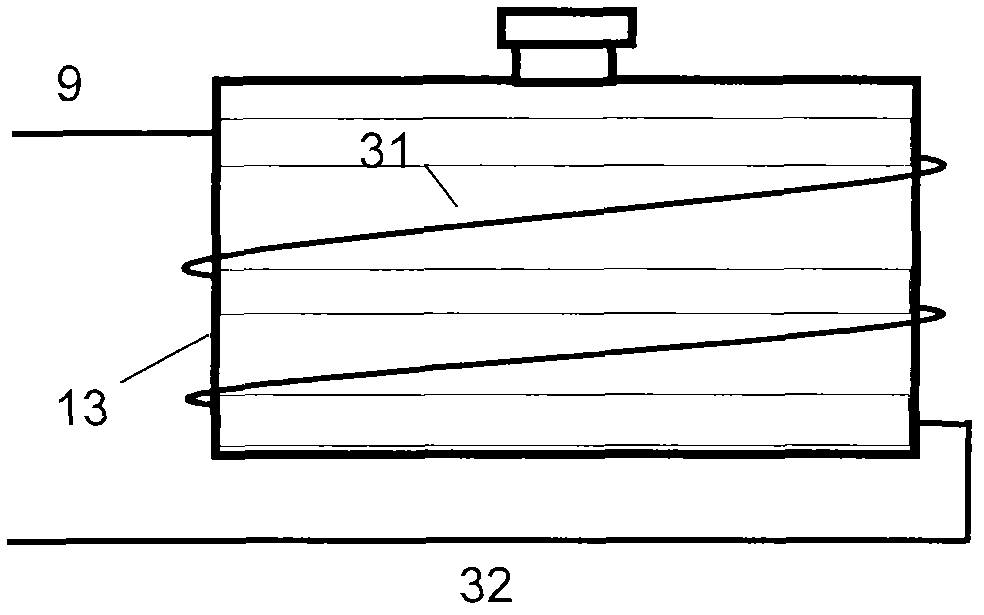

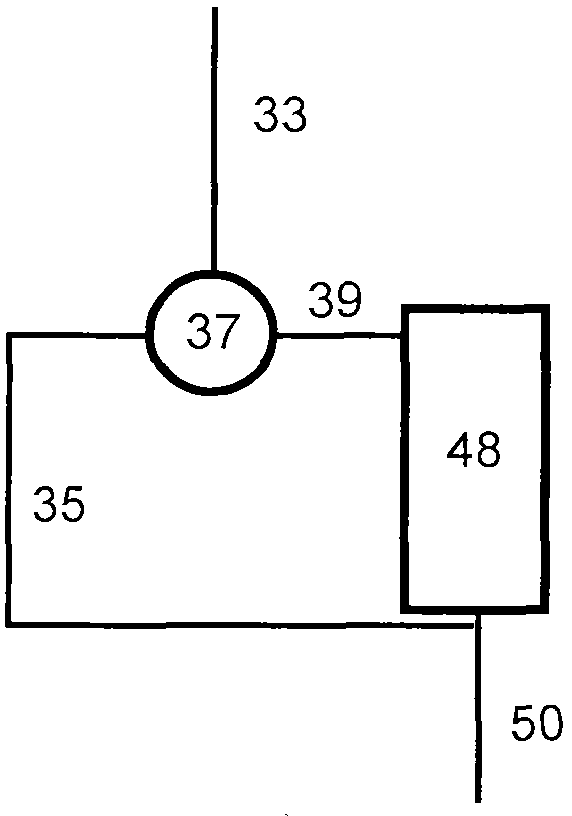

[0112] figure 1 It shows a form of the main structure of the aftertreatment device for purifying engine exhaust according to the present invention. The device includes additive 13, additive supply system, catalyst system 94, 96, 98 and electronic control unit (ECU) 52. The additive supply system includes a liquid tank 15, an additive solution supply line composed of a liquid path and a gas path, an air supply system, a system cleaning function, and a heating system. The electronic controller 52 includes on-vehicle monitoring and diagnosis (OBD) and communication functions.

[0113] (1) The engine 1 can be a diesel engine or a leanburn gasoline engine. The engine 1 establishes contact with the electronic controller 52 through various interfaces and transmits various information data about the engine to the electronic controller, including speed, load, coolant temperature, exhaust temperature, pressure and so on. The electronic controller 52 will rely on these information data to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com