High-temperature condensed water recycling and purifying system with ceramic membrane filter

A high-temperature condensate, ceramic membrane technology, applied in fixed filter element filters, filtration separation, water/sewage treatment, etc., can solve the problems of ineffective removal of iron ions, increased control points and maintenance points, and complicated processes. Achieve the effect of remarkable anti-pollution impact ability, saving high-temperature water resources, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to the following examples.

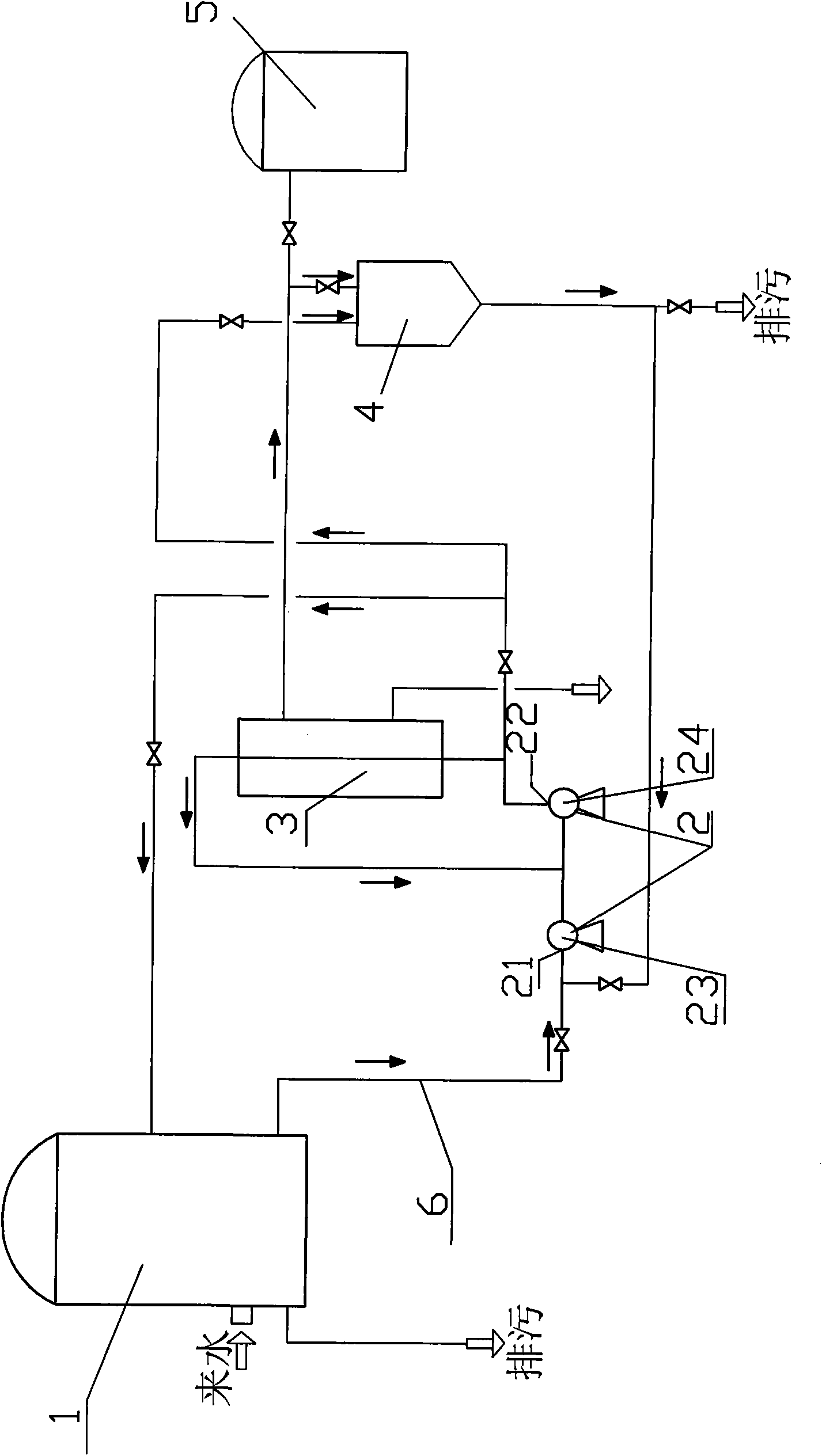

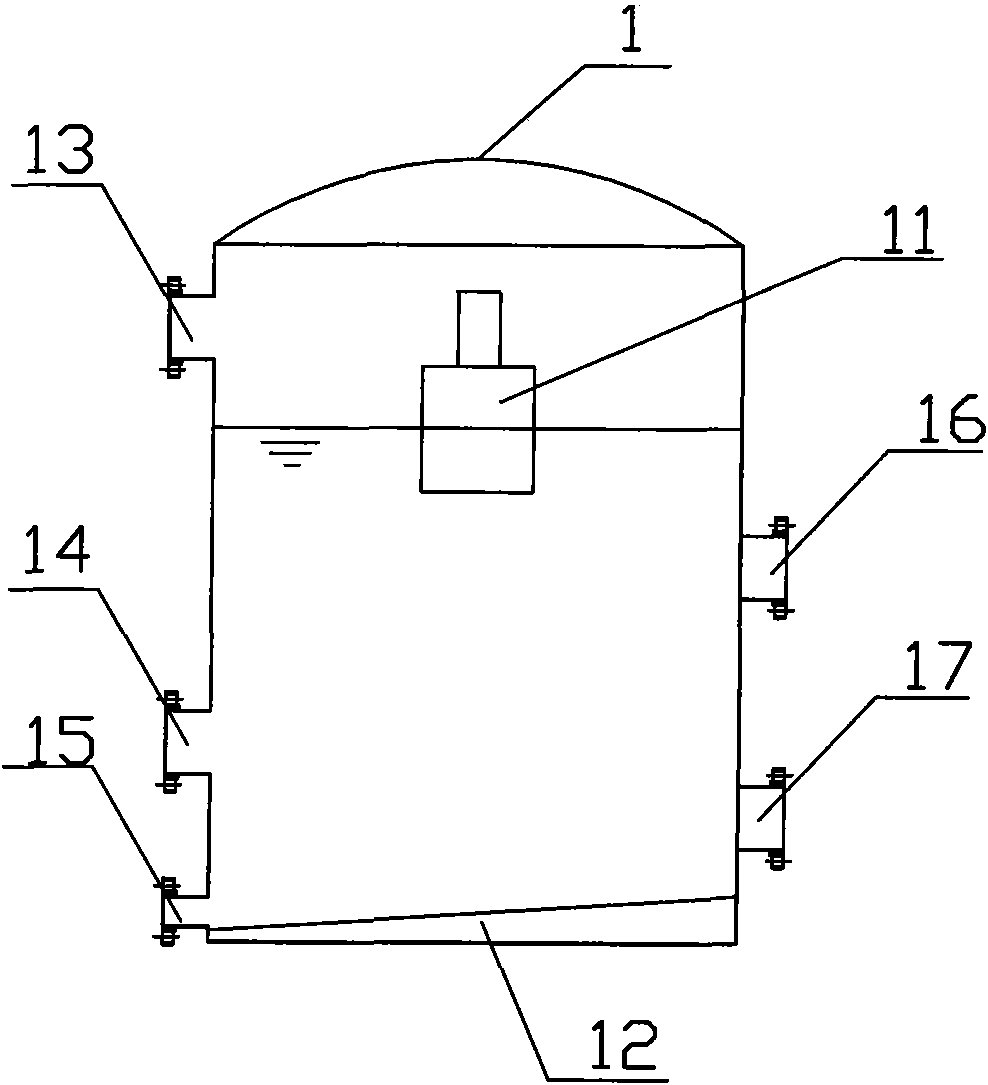

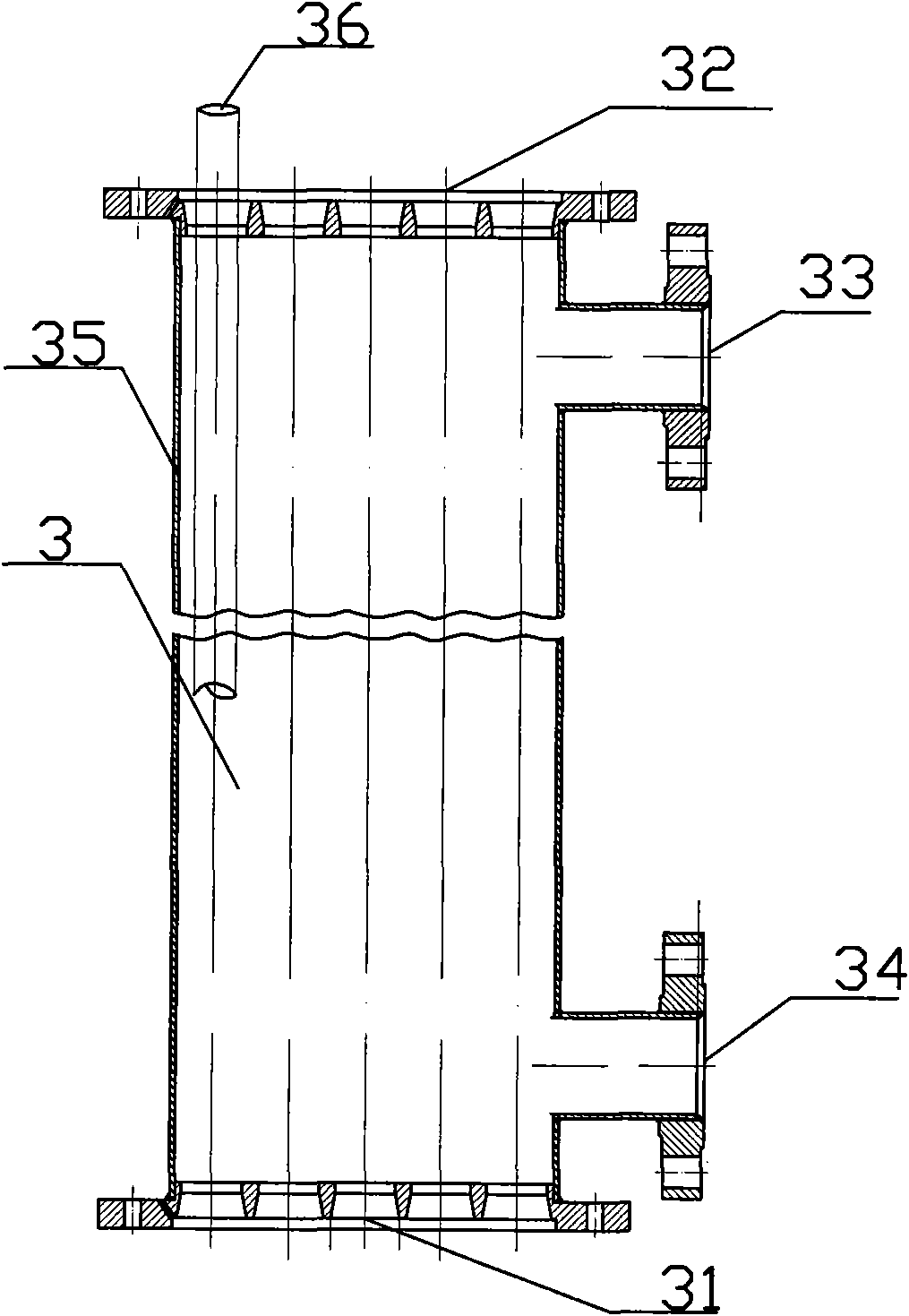

[0029] Such as figure 1 As shown, a ceramic membrane filter recovery and purification high-temperature condensed water system, which includes a concentration tank 1, a double pump structure 2, a ceramic membrane filter 3, a cleaning tank 4 and a water purification tank 5, the water outlet 17 of the concentration tank 1 passes through The pipeline 6 is connected to the water inlet 21 of the double-pump structure 2; the water outlet 22 of the double-pump structure 2 is connected to the circulating water inlet 31 of the ceramic membrane filter 3, and the circulating water outlet 32 of the ceramic membrane filter 3 The connecting pipe of the double-pump structure 2 is connected through the pipeline 6, and the water purification port 33 of the ceramic membrane filter 3 is connected to the water purification tank ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com