Synchronous dust removing device

A technology of dust removal device and synchronous transmission, applied in laser welding equipment, electrical components, climate sustainability, etc., can solve the problems of shortened life of wiring aging motor, low dust removal efficiency, polluted equipment, etc., and achieve good dust removal effect and dust collection. Small area, high dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

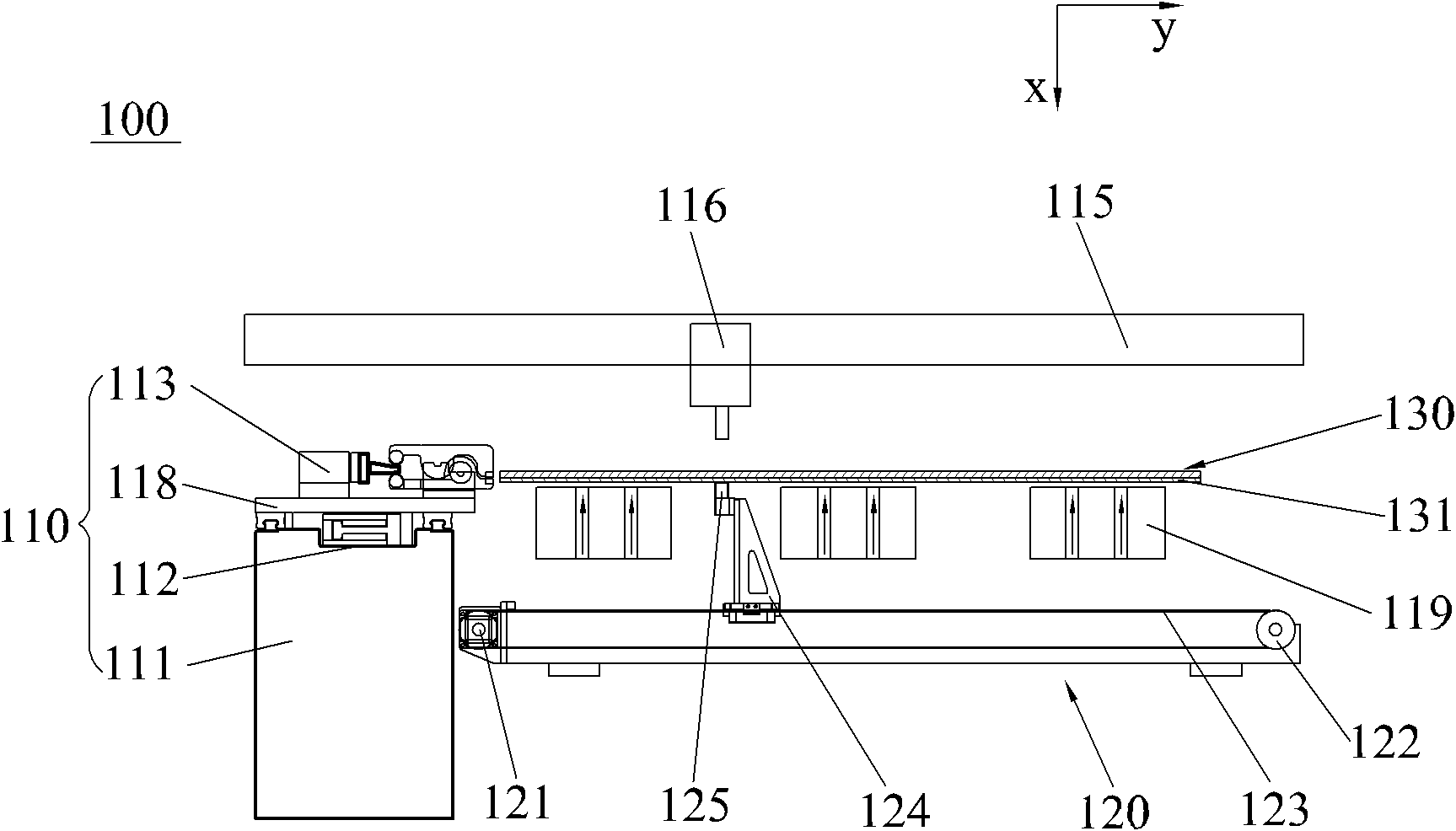

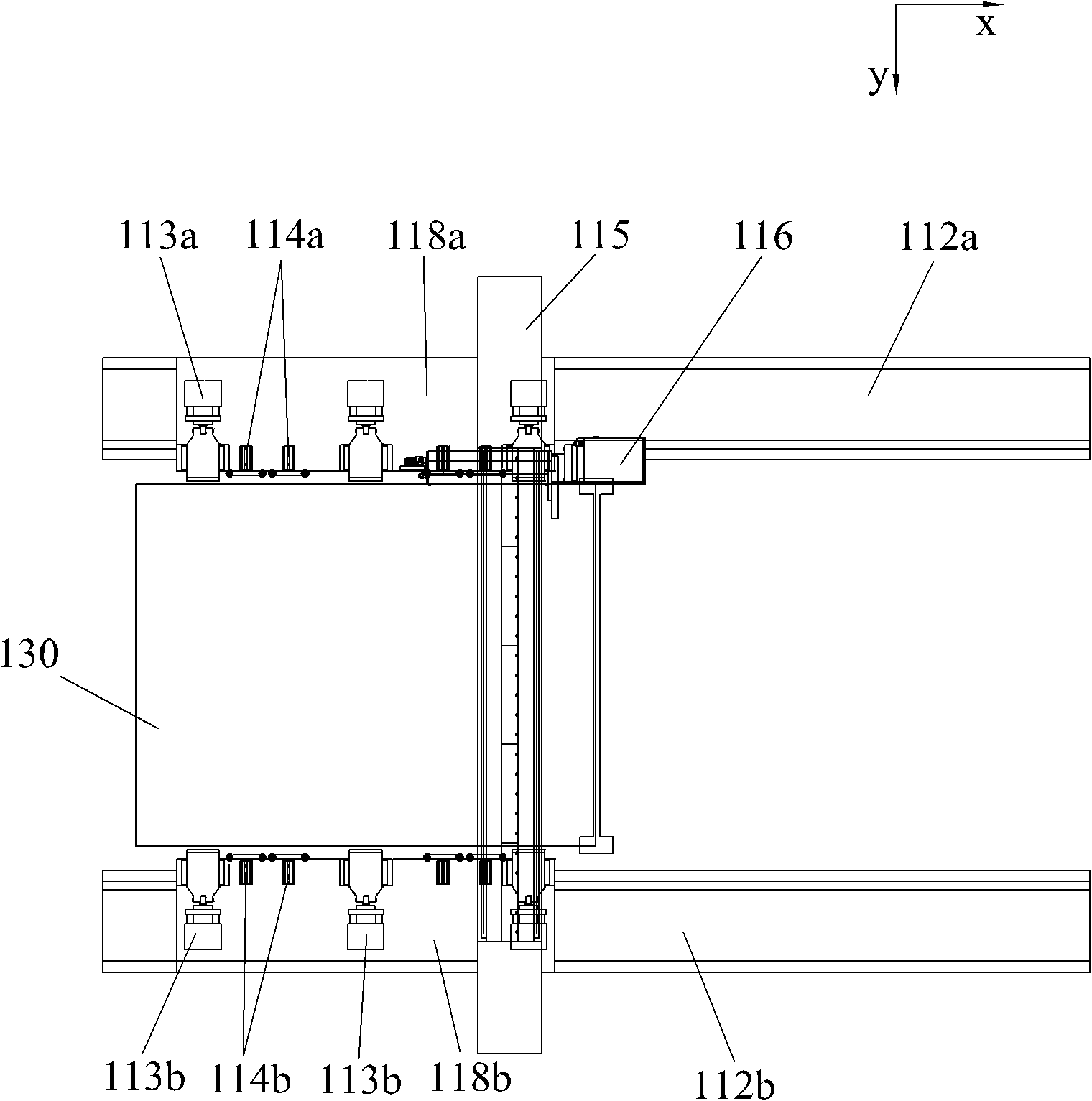

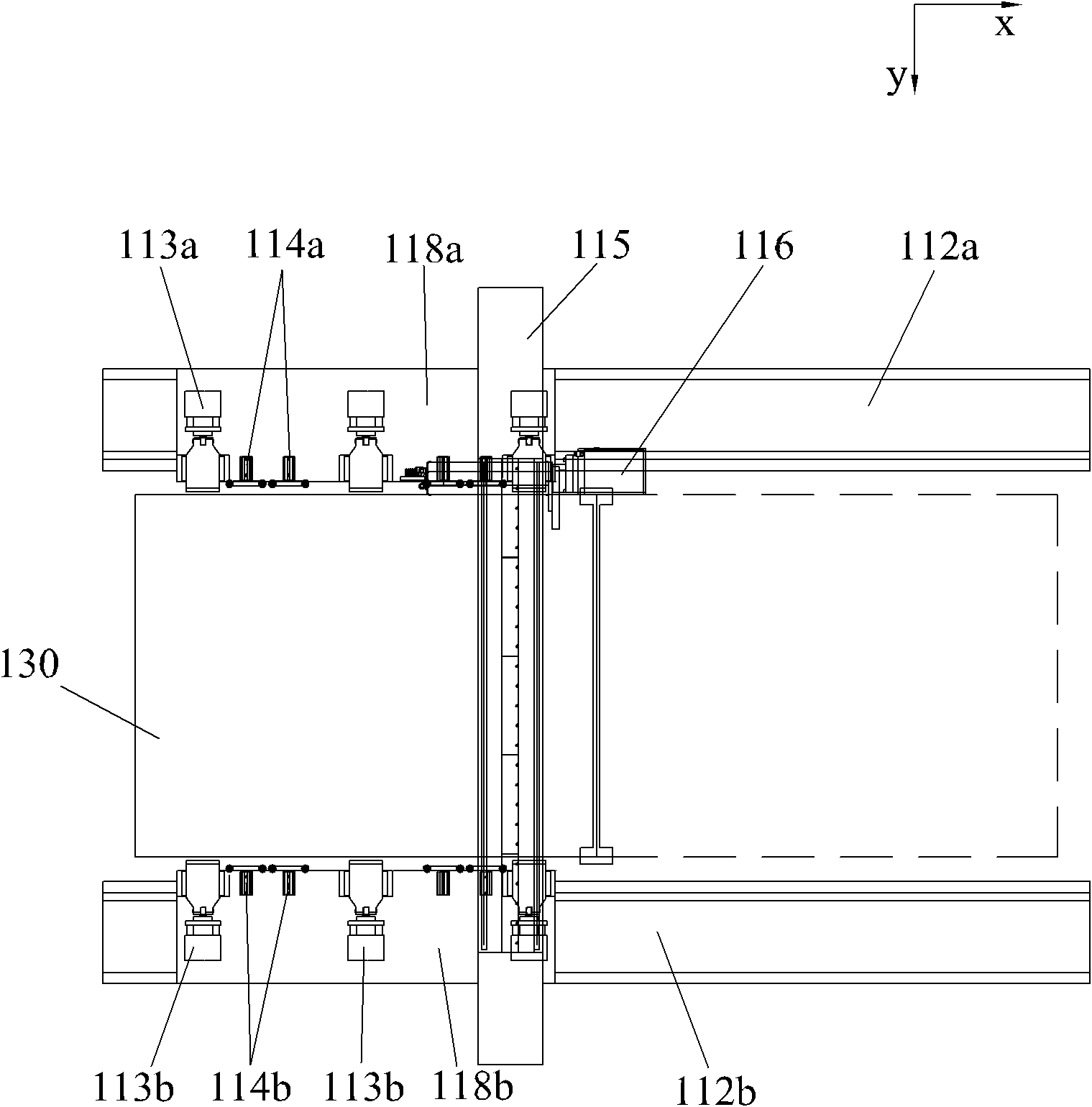

[0018] Such as figure 1 , figure 2 As shown, the synchronous dust removal device 100 of the present invention includes a control unit (not shown), a processing unit 110 and a dust removal unit 120, and the processing unit 110 and the dust removal unit 120 are all connected to the control unit; the processing unit 110 includes an installation platform 111, a laser track 115 , laser moving mechanism (not shown), laser generator 116 and air-floating platform 119, two mutually parallel gripper rails 112a, 112b are arranged on the installation platform 111, and sliding blocks 118a, 112b are slidably connected on the gripper rail 112a The upper sliding block is connected with a sliding block 118b, the handle 113a is connected to the handle track 112a through the sliding block 118a, the handle 113b is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com