Hydrotalcite flame-retardant polypropylene (PP) composite material and preparation method thereof.

A technology of flame retardant polypropylene and composite materials, applied in the field of polypropylene modification, can solve the problems affecting the application of flame retardant polypropylene, unstable flame retardant performance, reduced gloss of products, etc., achieving low specific gravity, good gloss, improved gloss, The effect of maintaining gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0027] The polypropylene is homopolypropylene imported from South Korea; the compatibilizer is commercially available maleic anhydride grafted polypropylene, the flame retardant is commercially available decabromodiphenylethane and antimony trioxide, and the antioxidant is CIBA The company's 168 and 1010 use calcium stearate as a lubricating and dispersing agent.

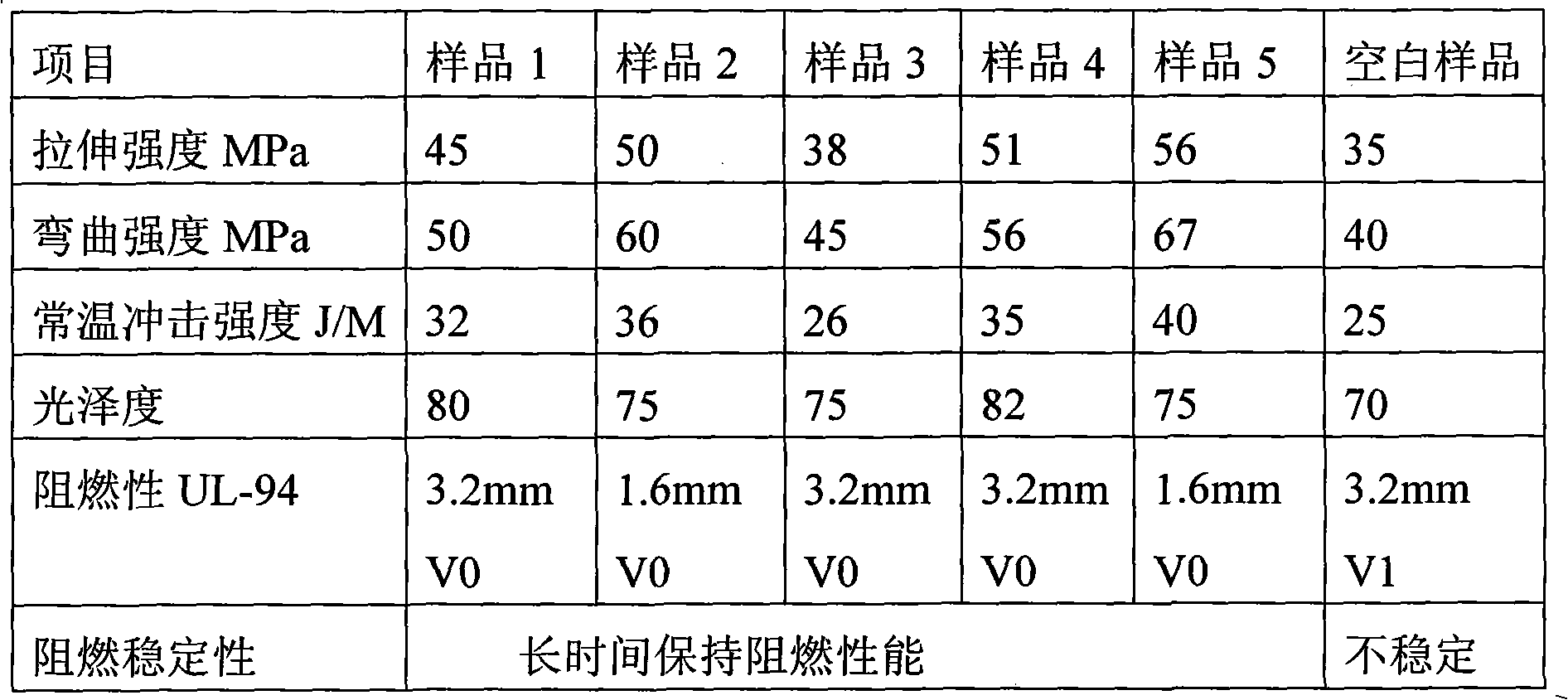

[0028] Product ratio 1-5 Table 1

[0029] raw material name

Example

1(wt%)

Example

2(wt%)

Example

3(wt%)

Example

4(wt%)

Example

5(wt%)

blank test

test

Homopolypropylene

65

64

66

63

60

69

Compatibilizer

3

3

3

6

6

3

Decabromodiphenylethane

16

18

18

16

18

18

8

9

9

8

9

9

7

5

3

6

6

0

1010 / 168(1∶1)

0.5

0.5

0.5

0.5

0.5

0.5

Calcium steara...

Embodiment 6

[0036] A preparation method of a hydrotalcite flame-retardant polypropylene composite material, the method comprising the following steps:

[0037] (1) Taking raw materials by weight percentage: polypropylene (PP) 74kg, melt index is 100g / 10min, grafting ratio is 1% maleic anhydride grafted polypropylene 5kg, weight ratio is 2: 1 decabromo 10kg of the mixture of diphenylethane and antimony trioxide, 10kg of hydrotalcite, 0.25kg of antioxidant (1010), 0.25kg of antioxidant (168), 0.5kg of barium stearate;

[0038] Described hydrotalcite is the flame retardant stabilizer of composite material, and its chemical composition is [MII 1-xMIIIx(OH) 2 ]x+(An - ) x / n mH 2 O, where MII is the divalent metal cation Mg 2+ ; MIII is a trivalent metal cation Al 3+ ; An- is the anion CO 3 2- , x is 0.22, n is 4, and m is 4.

[0039] (2) Put polypropylene, compatibilizer, flame retardant, hydrotalcite, antioxidant, lubricating dispersant into the high mixer and mix for 5 minutes;

[0...

Embodiment 7

[0043]A preparation method of a hydrotalcite flame-retardant polypropylene composite material, the method comprising the following steps:

[0044] (1) Taking raw materials by weight percentage: polypropylene (PP) 85%, melt index is 150g / 10min, grafting ratio is 2% maleic anhydride grafted polypropylene 1kg, weight ratio is 2: 1 ten 12.8kg of the mixture of brominated diphenylethane and antimony trioxide, 1kg of hydrotalcite, 0.05kg of antioxidant (1010), 0.05kg of antioxidant (168), 0.1kg of zinc stearate;

[0045] Described hydrotalcite is the flame retardant stabilizer of composite material, and its chemical composition is [M II 1-xMIIIx (OH) 2 ]x+(An - ) x / n mH 2 O, where M II is a divalent metal cation Ni 2+ ; MIII is a trivalent metal cation Cr 3+ ; An- is the anion OH - , x is 0.3, n is 3, and m is 8.

[0046] (2) Put polypropylene, compatibilizer, flame retardant, hydrotalcite, antioxidant, lubricating dispersant into the high mixer in sequence and mix for 7 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com