Method and device for monitoring state of ballastless track structure through fibber bragg grating sensing

A fiber grating and ballastless track technology, applied in track, track maintenance, road, etc., can solve the problems of complex installation, poor stability, complex system, etc., and achieve the effect of strong anti-interference ability, good stability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

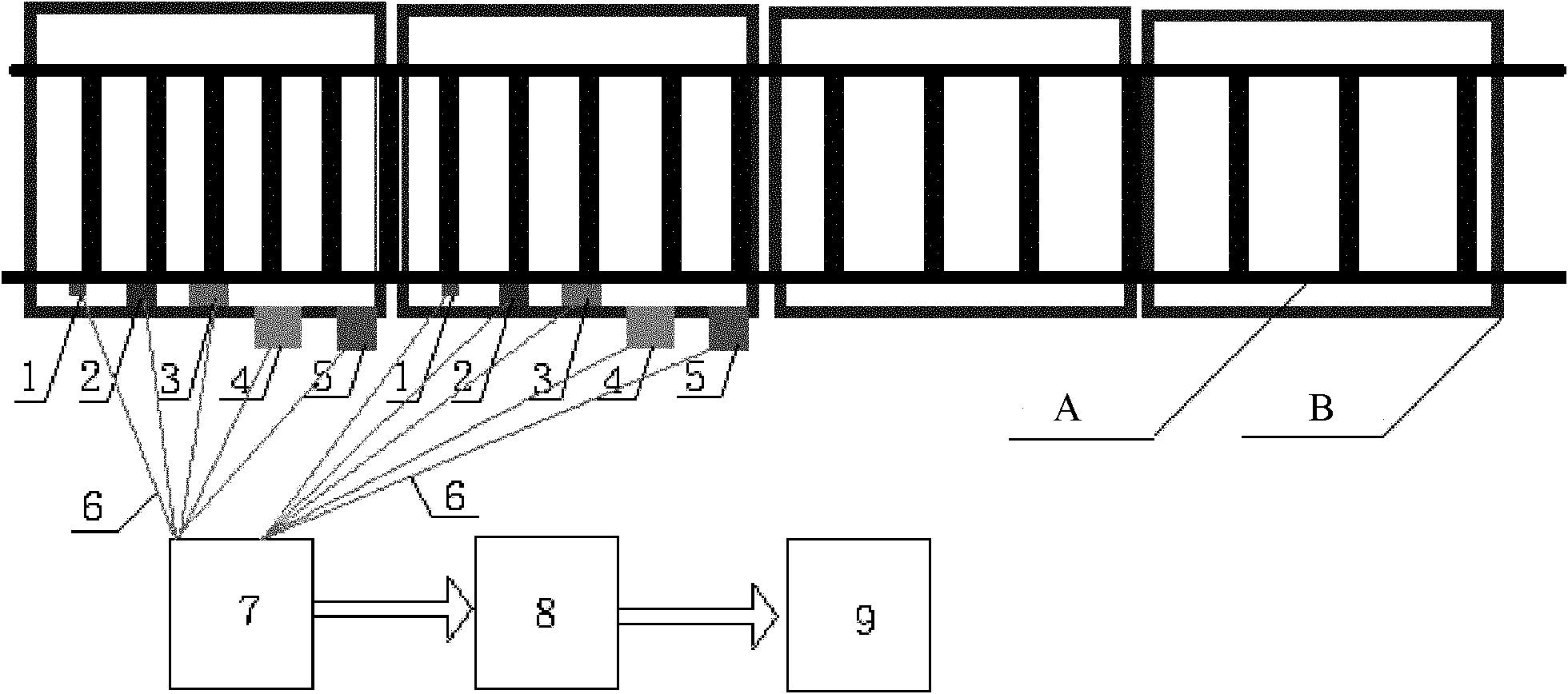

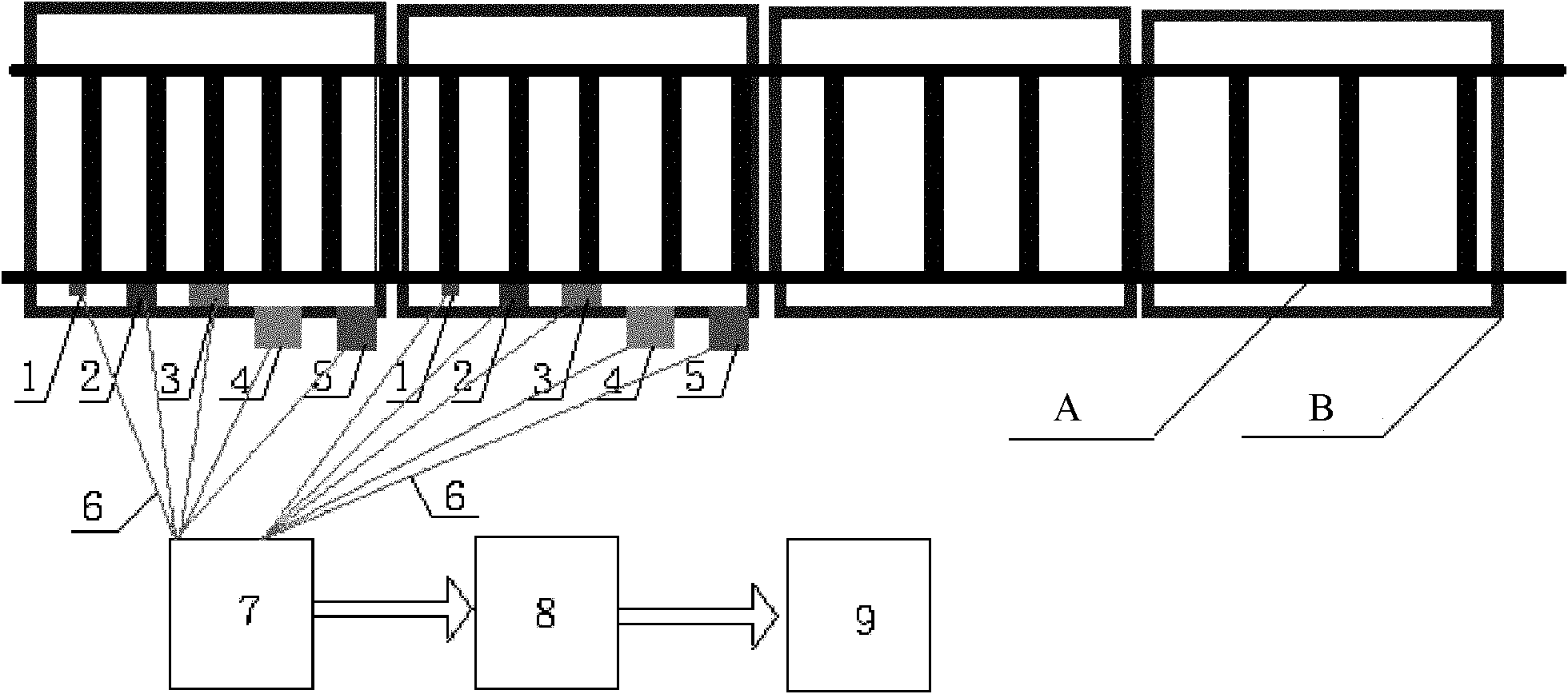

[0020] 1: The system device includes M optical fiber grating rail temperature and strain combined sensors 1, N optical fiber grating rail lateral displacement, longitudinal displacement and vertical displacement combined sensors 2, P optical fiber grating rail lateral acceleration, longitudinal acceleration and vertical acceleration combination Sensor 3, Q fiber grating plate ballast bed lateral displacement, longitudinal displacement and vertical displacement combined sensor 4, R fiber grating plate ballast bed lateral acceleration, longitudinal acceleration and vertical acceleration combined sensor 5, sensor shell, fixing device, auxiliary device, Transmission optical fiber 6, multi-channel fiber grating wavelength demodulator 7, data processing terminal 8, and alarm device 9.

[0021] 2: Fiber Bragg grating rail temperature and strain combined sensor 1. Fiber Bragg grating rail lateral displacement, longitudinal displacement and vertical displacement combined sensor 2. Fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com