Permanent magnet synchronous draining pump and a water tank water cooling system

A permanent magnet synchronous and water pump technology, which is applied to pump components, variable capacity pump components, and components of pumping devices for elastic fluids, etc. It can solve the problem of water pollution of the external whole machine, residual impurities and scale in the cooling system. and other problems, to achieve the effect of feasible process, good heat dissipation effect and easy structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

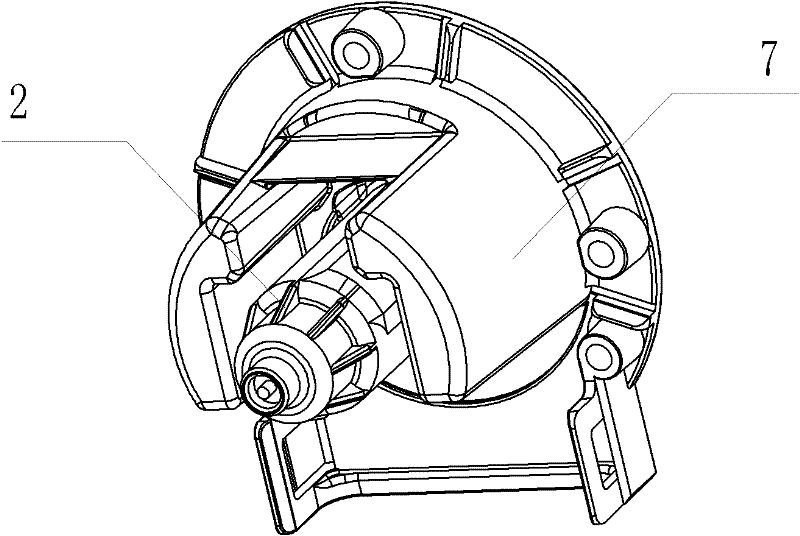

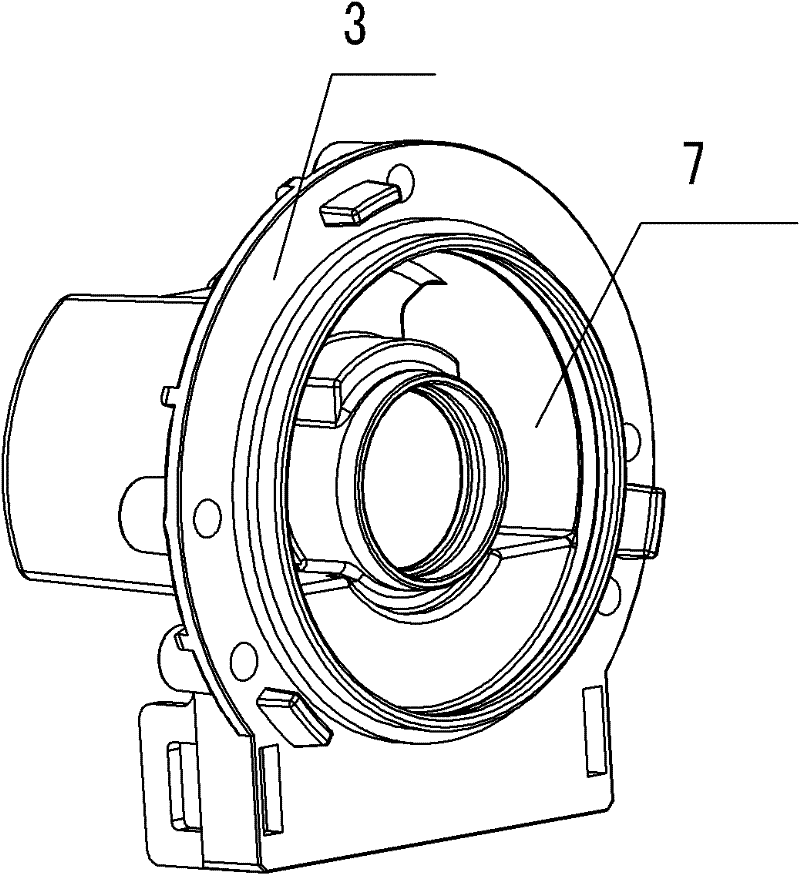

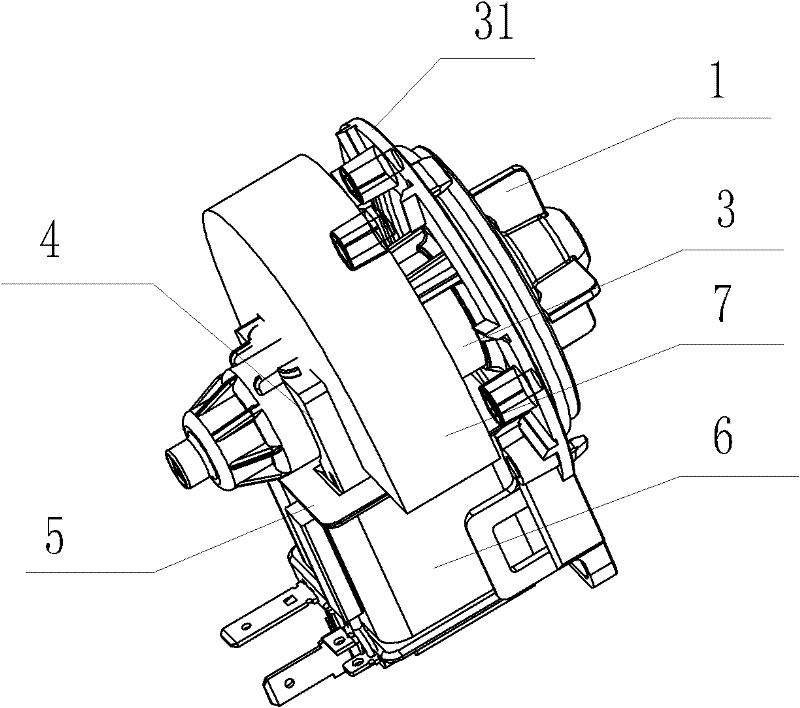

[0026] Such as Figure 2-4 As shown, it is a permanent magnet synchronous water pump, which includes pump structural components, motor components and water cooling components.

[0027] The pump structural components include an impeller 1 and a pump body 3 . The impeller 1 is linked to the motor rotor 2 through the transmission shaft; the pump body 3 accommodates and provides support for the motor assembly. The motor assembly includes a permanent magnet rotor 2 and a U-shaped stator core 4 , and the stator core 4 is wrapped around the permanent magnet rotor 2 . The tail of the stator core 4 is fixed with a plastic frame 5 on which a coil 6 is wound.

[0028] The water-cooling assembly mainly includes a closed water tank 7, which is designed as a C-shaped box according to the U-shaped shape surrounding the stator core 4, and the opening is an accommodating cavity 70 for the stator core 4, such as Figure 5 shown. The two legs of the stator core 4 are inserted into the accomm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com