Base material for printed circuit board

A technology for printed circuit boards and substrates, which is used in circuit substrate materials, printed circuit components, and secondary processing of printed circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

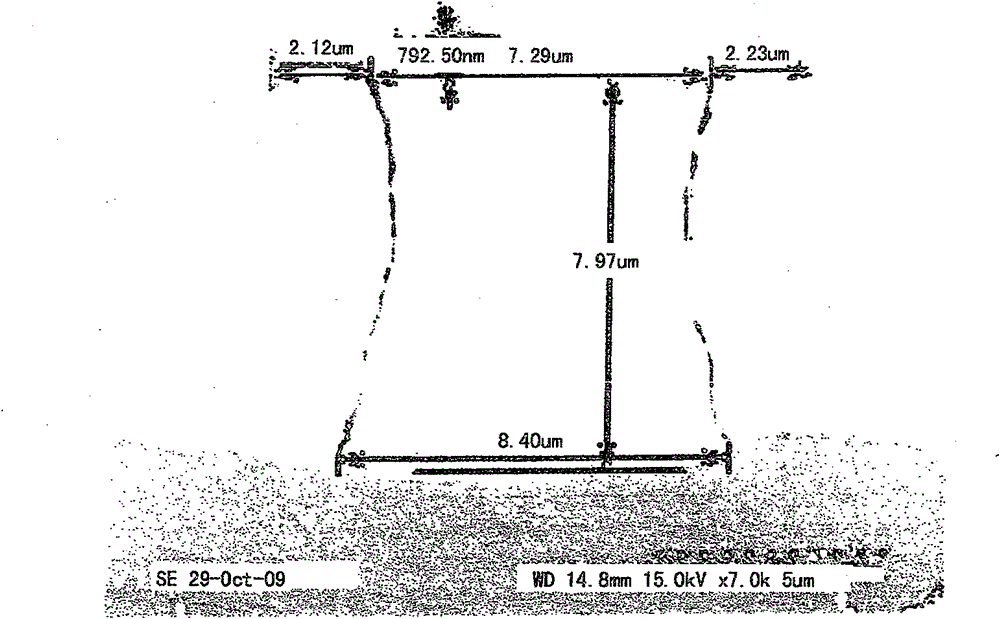

[0018] See first figure 2 , The base material used for printed circuit boards of the present invention is shown in FIG. 10 , which has a main layer 12 and a surface layer 14 . The main layer 12 can be a copper metal layer or a copper alloy layer. In this embodiment, its thickness is about 7.97um. The surface layer 14 is a nickel metal layer. In this embodiment, its thickness is about 0.792um. can be removed.

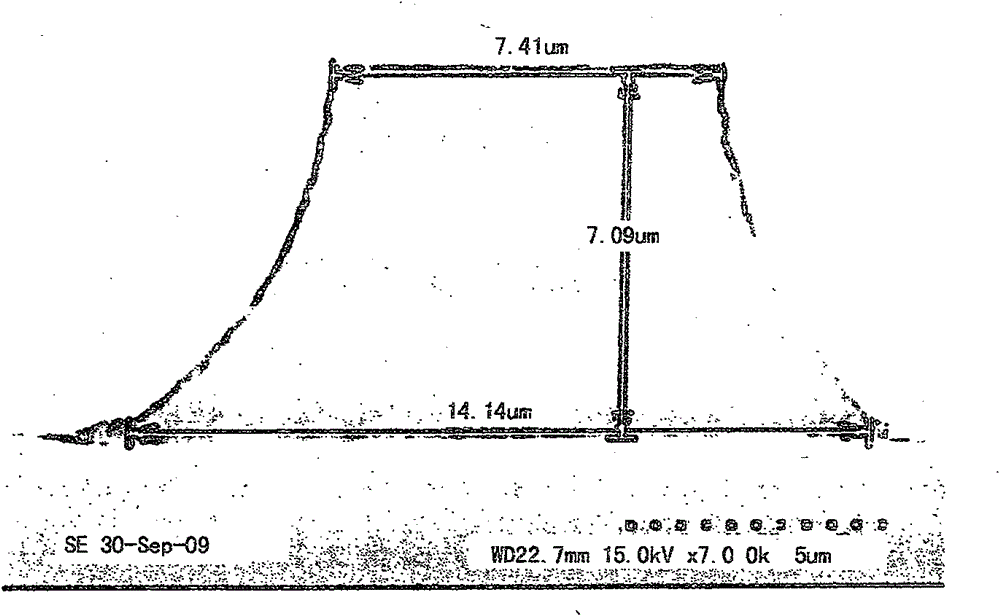

[0019] Such as image 3 As shown, in actual manufacturing, the main layer 12 is first arranged on an insulating substrate 20, and then the surface layer 14 is arranged on the surface of the main layer 12, wherein the arrangement method can be processes such as coating, attachment or electroplating, and then Then perform subsequent etching steps, such as coating the photoresist layer 30 , forming a circuit trace pattern mask layer, etching procedures, and removing the mask layer and the surface layer 14 . Of course, the complete substrate 10 can also be prepared in ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com