Preparation process of high volume fraction silicon particle enhanced aluminum based composite material

A composite material and particle-reinforced technology, which is applied in the field of preparation of high-volume silicon particle-reinforced aluminum-based composite materials, can solve the problems of difficulty in controlling the particle size and morphology of composite material interfaces, poor mechanical properties and machinability of materials, and high Bulk Si/Al is not dense, etc., to achieve excellent comprehensive performance, improved fracture toughness, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

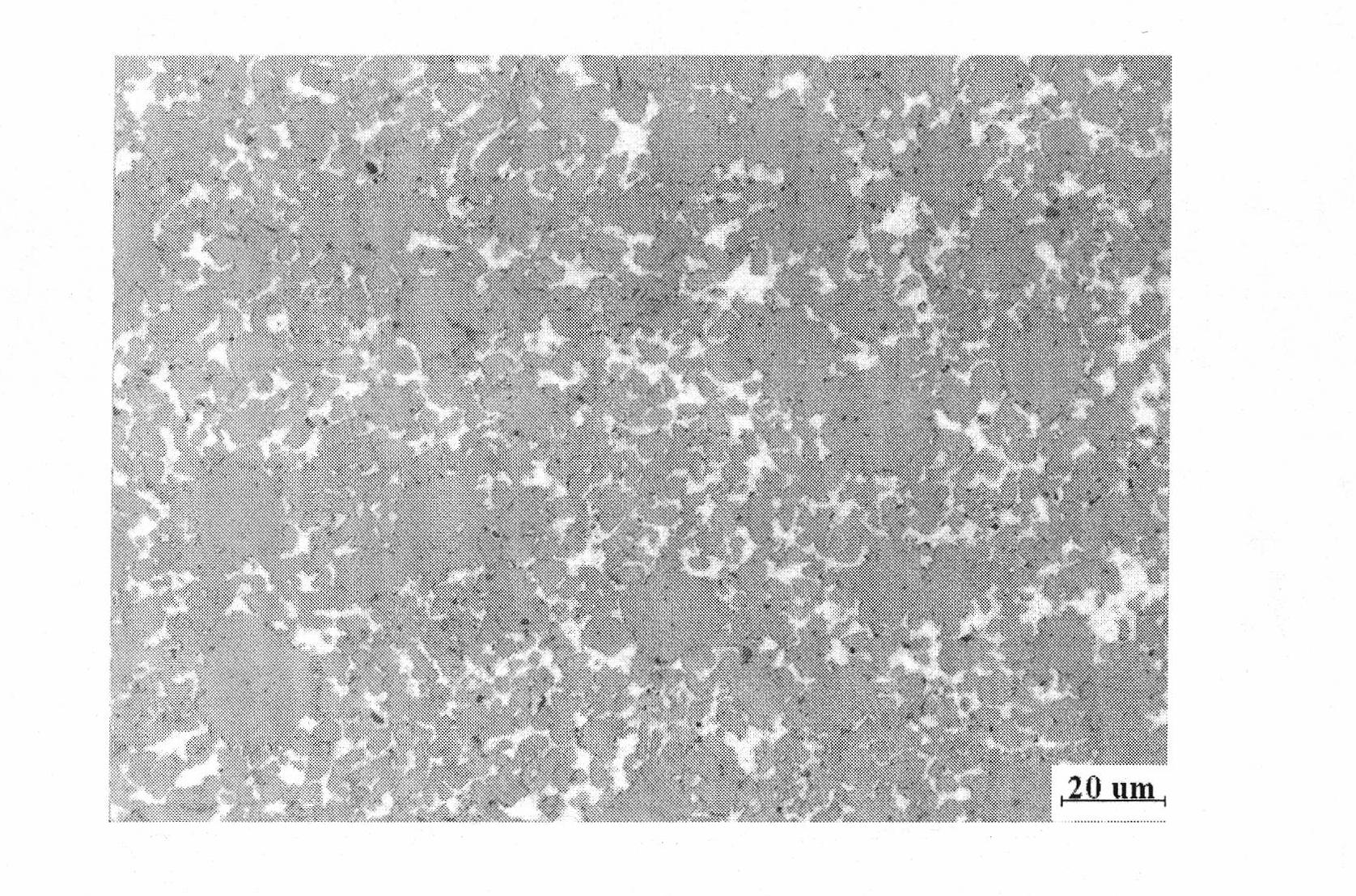

[0031] The composite material prepared in this embodiment is 70vol.% Si / Al (that is, the content of Si is 70vol.%; the content of 2024 alloy is 30vol.%); the preparation method adopts the following technical solutions: (1) The particle size is- The 325 mesh atomized aluminum alloy powder and the surface-treated silicon powder are uniformly mixed according to the mass ratio of 1:2.01. The aluminum alloy powder is 2024 alloy powder, and the aluminum powder is d 0.5 It is 23.647μm, that is, more than 50wt.% of the powder particle size is smaller than this size, the particle size of Si powder is 0.3-18μm, 0.5 It is 4.372μm. The surface treatment method of Si powder is to form a layer of SiO with a thickness of 10 nanometers to 50 nanometers on the surface of Si powder through high temperature oxidation. 2 Thin film, high temperature oxidation temperature is 750℃, average particle size of Si powder after treatment d 0.5 It is 4.397μm; (2) The mixed powder is put into a metal mold with ...

Embodiment 2

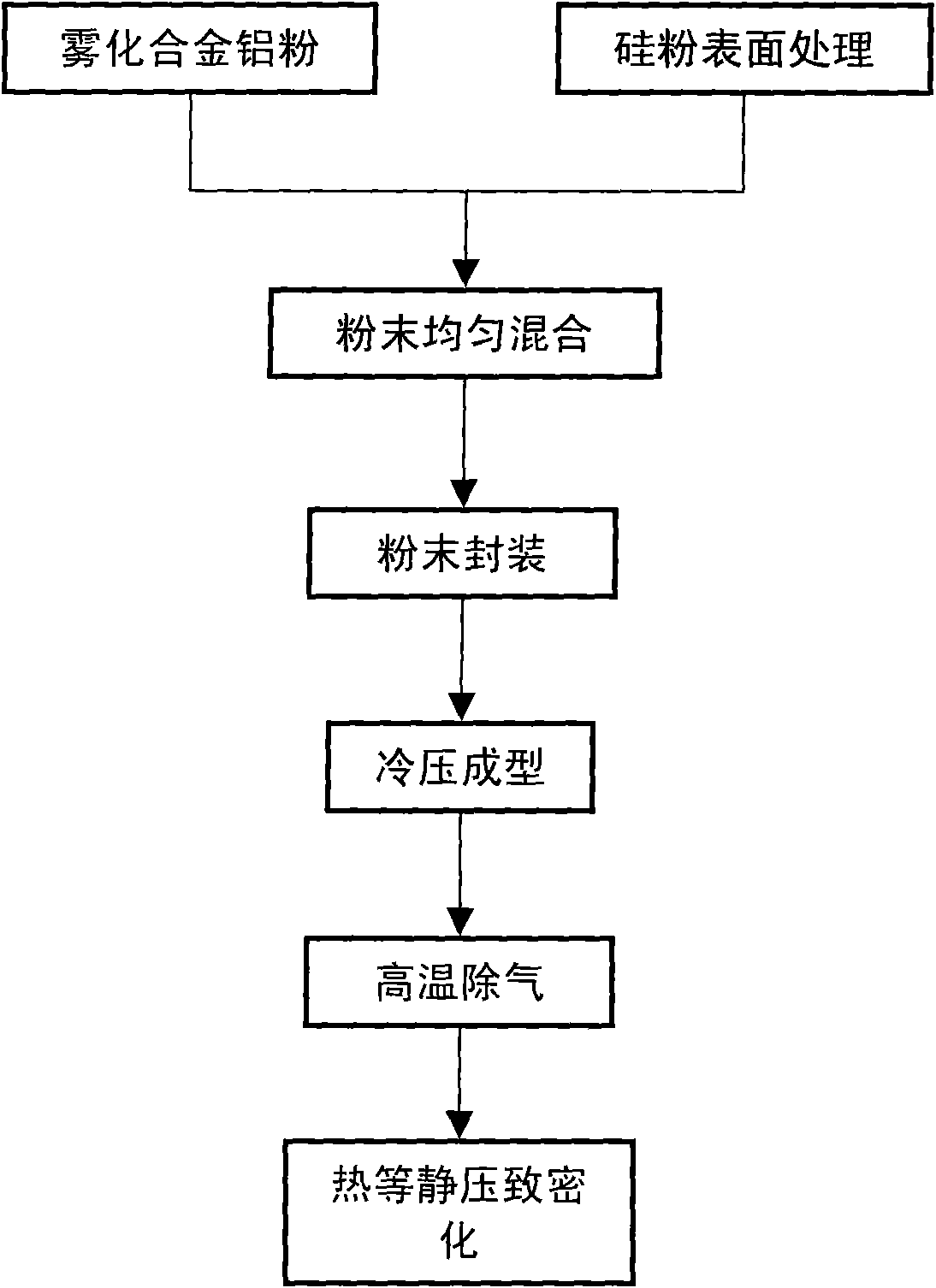

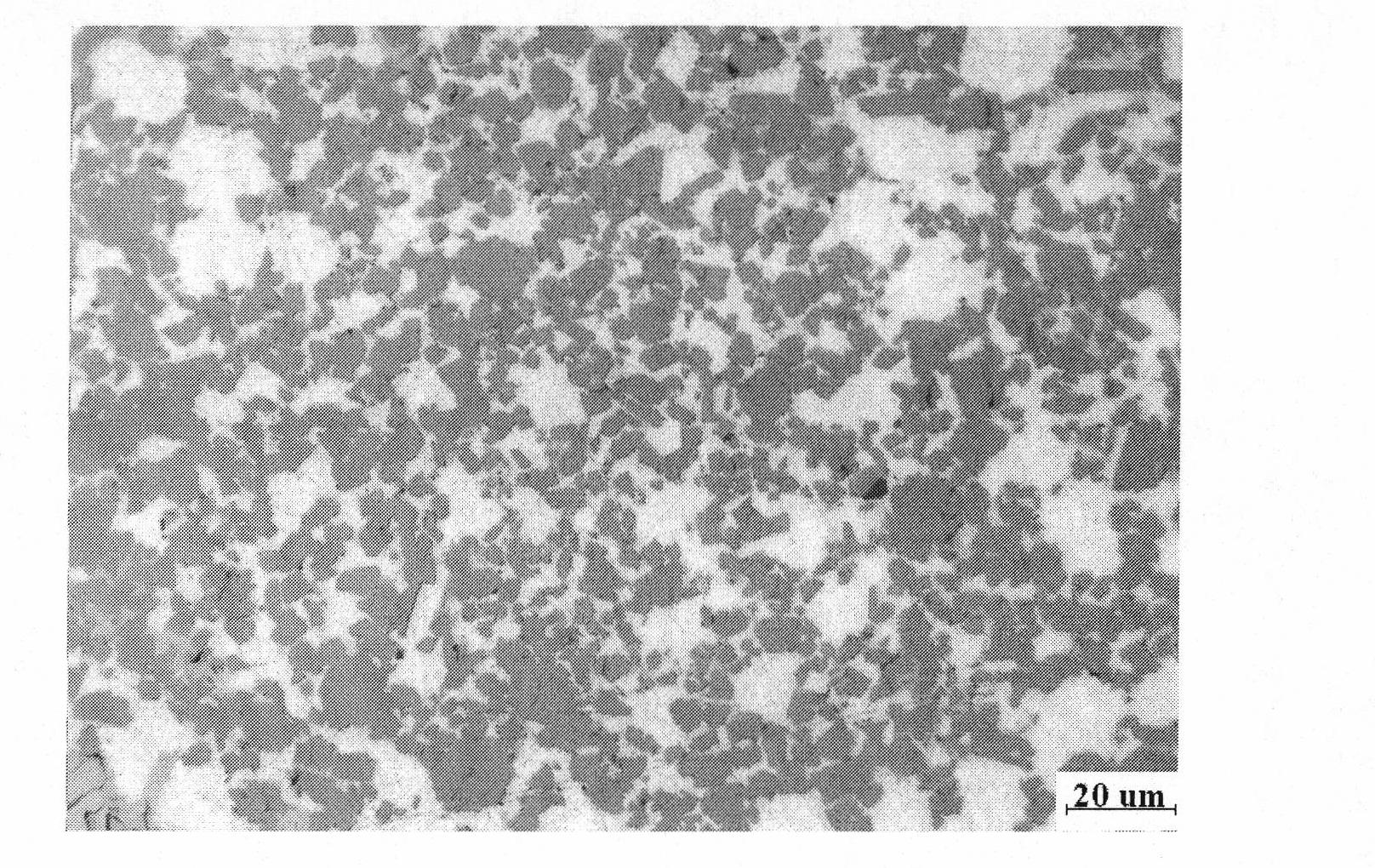

[0037] The composite material prepared in this embodiment is 50vol.% Si / Al (that is, the content of Si is 50vol.%; the content of 2024 alloy is 50vol.%). The preparation process flow chart is as figure 2 Shown; such as figure 2 As shown, the atomized aluminum alloy powder is mixed with the silicon powder after surface treatment. After the powder is uniformly mixed, the powder is packaged and cold isostatic pressing is performed, and then the high temperature degassing and hot isostatic pressing are densified to produce High-volume Si / Al particle reinforced composite material. The technical scheme is detailed as follows: (1) The prefabricated aluminum alloy powder and the surface-treated silicon powder are uniformly mixed in a mass ratio of 1:0.86. The aluminum alloy powder is 2024 alloy powder, which is atomized alloy aluminum with a particle size of -325 mesh. Powder, aluminum powder d 0.5 It is 23.647μm, that is, more than 50wt.% of the powder particle size is smaller than ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com