10B boron carbide and preparation method thereof

A technology of boron carbide and boric acid powder, which is applied in the field of 10B boron carbide and its preparation, can solve the problems of wasting raw materials and increasing production costs, and achieves the effects of low secondary ray energy, avoiding oxidation loss and superior high temperature properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

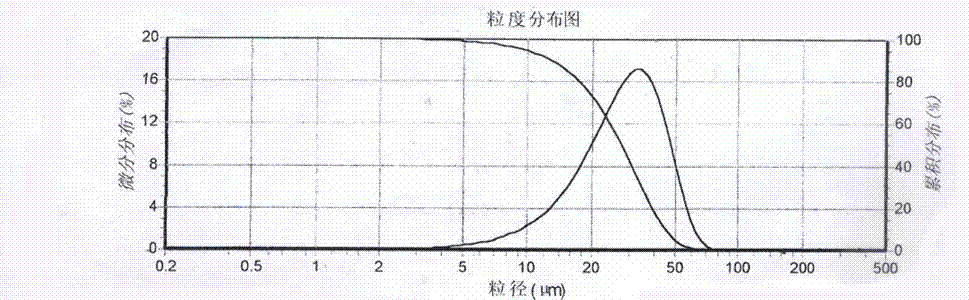

[0024] (1) First by mass parts 10 B abundance is 99% (at.) 75 parts of boric acid powder and 25 parts of graphite powder are mixed in mixer for 5 hours, obtain mixed powder, wherein boric acid powder purity is 99.9wt%, median diameter d 50 50 <4μm;

[0025] (2) Compress the mixed powder into tablet granules with a diameter of 20mm and a thickness of 10mm in a tablet press;

[0026] (3) Put the mixed powder pellets into a ceramic bowl, roast and dehydrate in stages in a muffle furnace, and roast at 100°C for 60 minutes to dehydrate boric acid into metaboric acid and tetraboric acid, and then Roasting at 700°C for 60 minutes to completely dehydrate metaboric acid and tetraboric acid into boric anhydride (B 2 o 3 );

[0027] (4) After the dehydrated mixed powder tableting particles undergo carbonization reaction at a temperature of 2100 ° C, keep warm for 60 minutes, wherein the carbonization reaction is to put the mixed powder tableting particles into an induction heat...

Embodiment 2

[0031] (1) First by mass parts 10 B abundance is 60% (at.) boric acid powder 80 parts and graphite powder 20 parts are mixed in mixer for 8 hours, obtain mixed powder, wherein boric acid powder purity is 99.9wt%, median particle size d 50 50 <4μm;

[0032] (2) Compress the mixed powder into tablet granules with a diameter of 20mm and a thickness of 10mm in a tablet press;

[0033] (3) Put the mixed powder pellets into a ceramic bowl, roast and dehydrate in stages in a muffle furnace, and roast at 150°C for 60 minutes to dehydrate boric acid into metaboric acid and tetraboric acid, then Roasting at 600°C for 60 minutes to completely dehydrate metaboric acid and tetraboric acid into boric anhydride (B 2 o 3 );

[0034] (4) After the dehydrated mixed powder tableting granules are subjected to a carbonization reaction at a temperature of 1855 ° C, they are kept warm for 60 minutes, wherein the carbonization reaction is to put the mixed powder tableting granules into a 20...

Embodiment 3

[0038] (1) First by mass parts 10 B abundance is 25% (at.) boric acid powder 83 parts and graphite powder 17 parts are mixed in mixer for 6 hours, obtain mixed powder, wherein boric acid powder purity is 99.9wt%, median particle size d 50 50 <4μm;

[0039] (2) Compress the mixed powder into tablet granules with a diameter of 20mm and a thickness of 10mm in a tablet press;

[0040] (3) Put the mixed powder tablet granules into a ceramic bowl, roast and dehydrate in stages in a muffle furnace, and roast at 200°C for 60 minutes to dehydrate boric acid into metaboric acid and tetraboric acid, and then Roasting at 500°C for 60 minutes to completely dehydrate metaboric acid and tetraboric acid into boric anhydride (B 2 o 3 );

[0041] (4) Make the dehydrated mixed powder pellets undergo a carbonization reaction at a temperature of 2000°C, wherein the carbonization reaction is to put the mixed powder pellets into a 60 kvA electric arc furnace, and heat and carbonize in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com