Method of artificial construction of root holes in wetland

A wetland and artificial technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult renewal, high soil viscosity, low hydraulic conductivity, etc. Improved hydraulic conductivity, high retention efficiency, and reduced soil bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

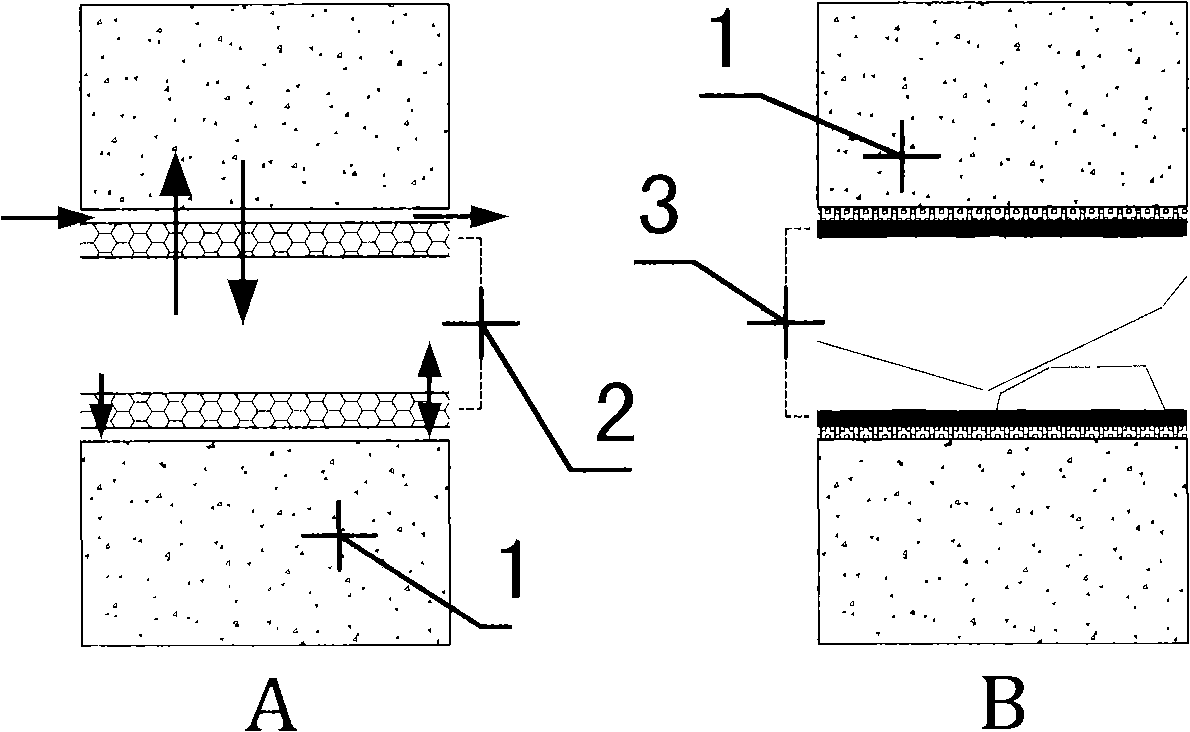

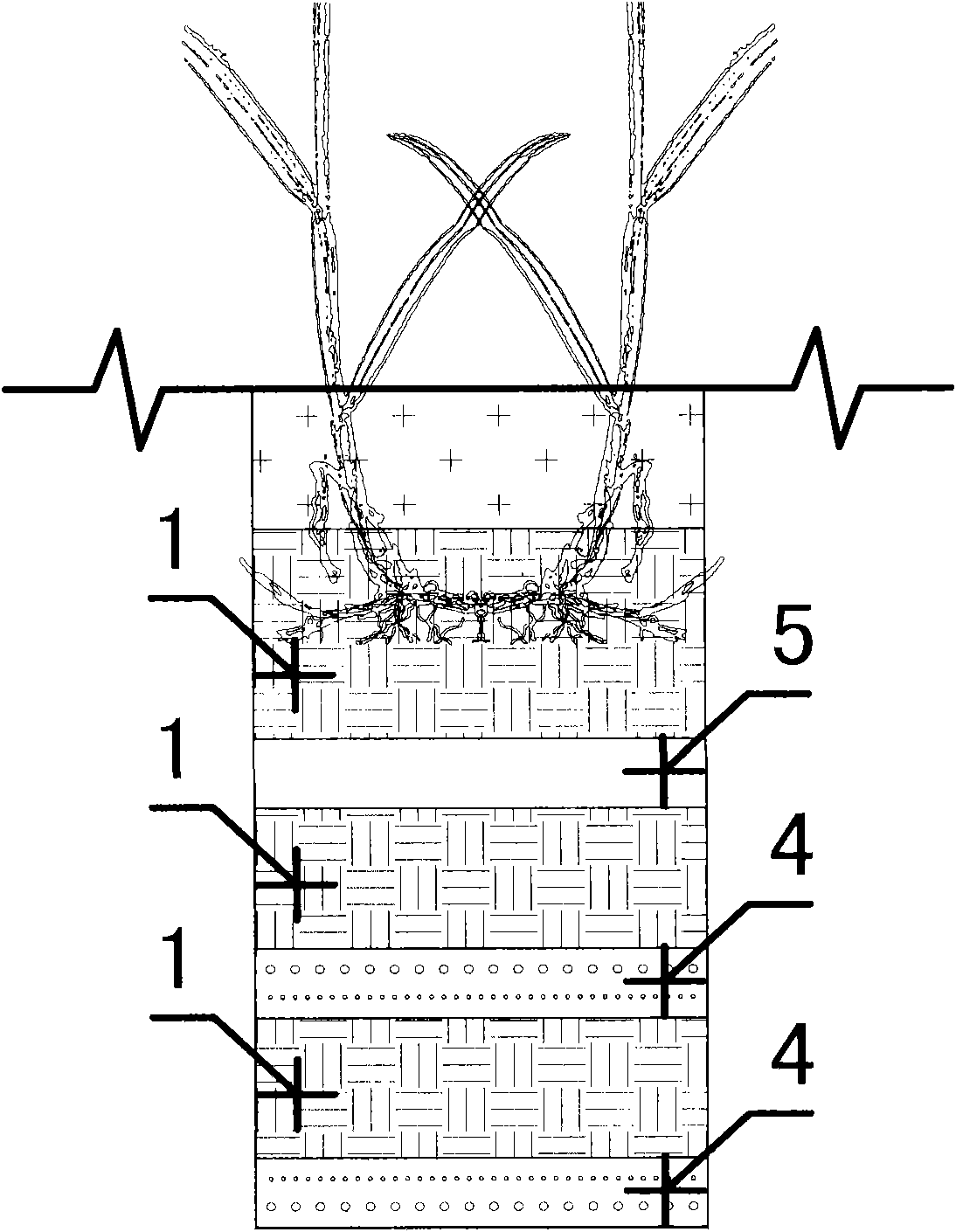

[0037] figure 2 Example 1 of the present invention is shown, wherein the total thickness of the constructed wetland soil layer is about 60 cm. Among them, two layers of dry straw are pre-embedded at the bottom of the wetland. The selected plant straw is composed of corn straw and rape straw, and its water content must be lower than 20%. The volume ratio of the two is 75%:25%. After calculation, the amount of straw per unit area of wetland is: 18 tons / ha of corn straw; 12 tons / ha of rapeseed straw. The corn stalks used are 1.6-2m in length and 2-3cm in diameter, and the leaves are removed. Rapeseed straw has a length of 0.6-1m and a diameter of 2-5mm. The plant straw layer 4 in the wet area is constructed in a thick-thin + thin-thick laying pattern. The specific method is: after the bottom elevation of the wetland plant bed reaches the theoretical digging depth and is leveled, lay the first layer of straw (9 tons / ha of corn straw, covered with 6 tons / ha of rape straw); 1...

Embodiment 2

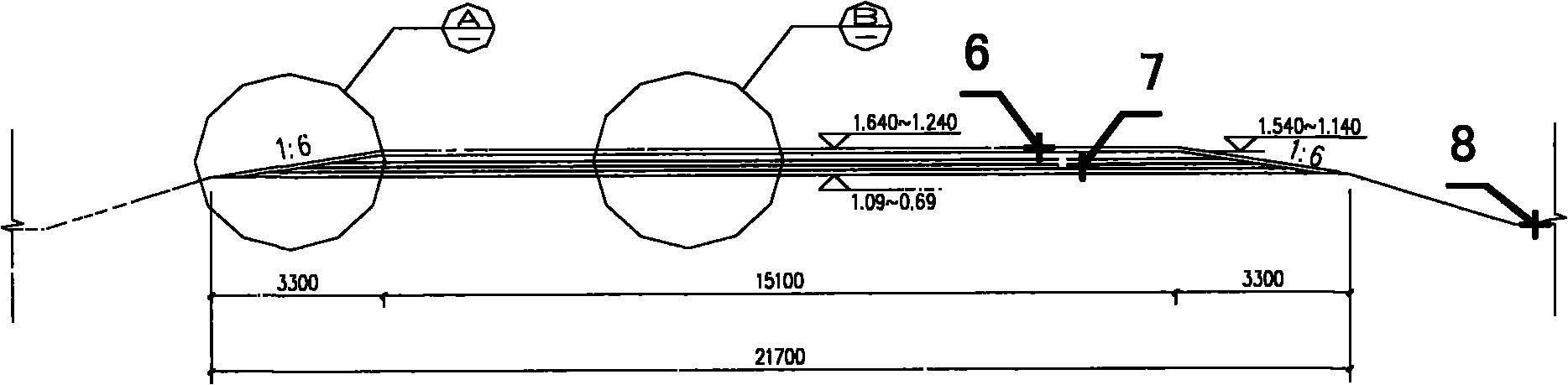

[0040] Figure 3 to Figure 6 Example 2 of the present invention is shown, wherein the slope ratio of the wetland plant bed slope is 1:6, the slope ratio of the wetland ditch slope is 1:3, and the depth of the wetland plant bed construction soil layer is 55cm. The range of plant straw laying is inside the wetland plant bed, and the outer distance of the edge laying is 0.5m inward from the edge of the plant bed slope. The width of the wetland plant bed is 21.7m, and the length varies in different areas of the wetland, ranging from 22m to 220m. When constructing large-scale artificially constructed root hole wetlands, there is a 40cm difference in elevation between the wetland plant bed surface 6 and the ditch bottom 8 in different areas of the wetland. The higher side flows to the lower side of the wetland, and the total slope ratio of the whole wetland is about 1:1750. In this embodiment, 4 layers of plant stalks are laid in the soil layer of the wetland plant bed. Figure 6...

Embodiment 3

[0042] Figure 7Embodiment 3 of the present invention is shown, in which the laying manner of plant straws in the wetland plant bed is coarse-fine-fine-coarse. This embodiment differs from Embodiments 1 and 2 in that each individual straw layer is laid in a coarse-fine-fine-coarse (4 sub-layer) mode, and the plant straw is in the corresponding layer Evenly distributed in the soil; the coarse-fine and fine-coarse arrangement of the plant stalks in Example 1 is symmetrically distributed, but there is a layer of 10cm natural soil layer in the middle; the plant stalks are alternately fine-coarse in Example 2 Arranged in a pattern, there is also a natural soil layer about 10cm thick in the middle. The laying mode of Embodiment 3 will be described in detail below. The total depth of the wetland plant bed construction soil layer is about 65cm, in which two layers of plant straw are laid, and the thickness of each layer is 15cm. These two straw layers are respectively laid in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com