Optical film with adhesive and optical laminate using same

A technology of optical laminates and adhesive layers, which is applied in the field of optical films, can solve problems such as poor compatibility, and achieve the effects of excellent reworkability, suppression of electrification, and suppression of whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

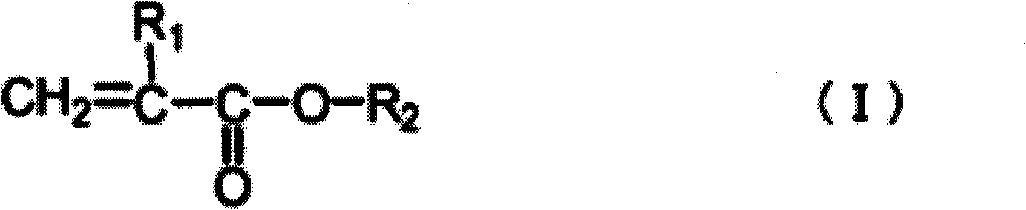

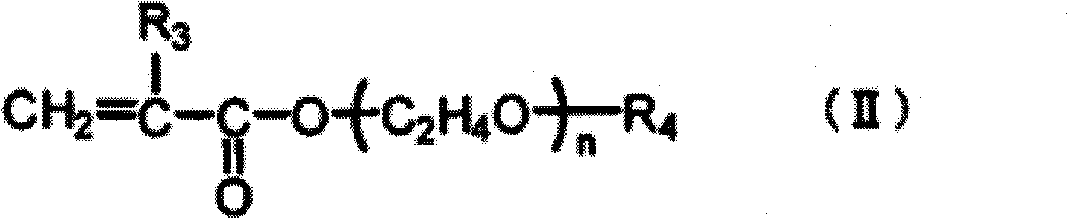

Method used

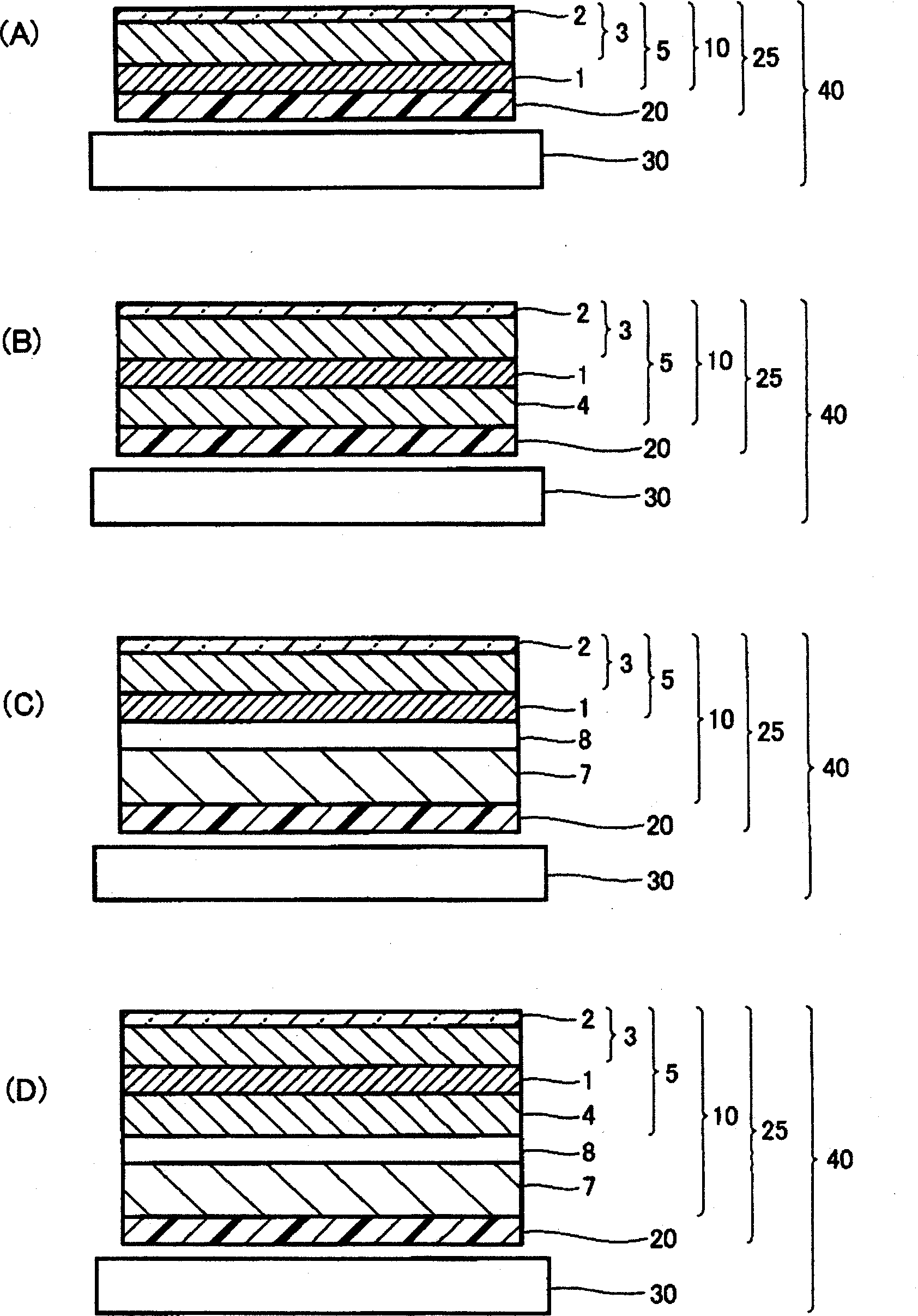

Image

Examples

Embodiment 1~4 and comparative example 1~2

[0216] (a) Manufacture of adhesive composition

[0217] With respect to 100 parts each of the solid content of the acrylic resins A to E obtained in Polymerization Examples 1 to 5, 3 parts each of the ionic compounds shown in Table 2, and 0.5 parts of the crosslinking agent "CORONATE L ", and 0.5 parts of silane-based compound "KBM-403", and ethyl acetate was added so that the solid content concentration was 13%, and an adhesive composition was prepared. In the column of ionic compounds in Table 2, the serial numbers of the above-mentioned ionic compounds 1 to 3 and whether they are solid or liquid at room temperature are shown.

[0218] (b) Preparation of optical film with adhesive

[0219] Each of the above-mentioned adhesive compositions was coated on a release-treated polyethylene terephthalate film (trade name "PET 3811", obtained from lintec (KK) using a coater, called a release layer ( separator)) to a thickness of 20 μm after drying, and dried at 90° C. for 1 minute to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com