Method for creating expert knowledge base for automatically training lower artificial limbs

An expert knowledge base, prosthetic technology, applied in the direction of muscle training equipment, prosthesis, sports accessories, etc., can solve the problems of complex methods and equipment, and achieve the effect of short time, good portability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

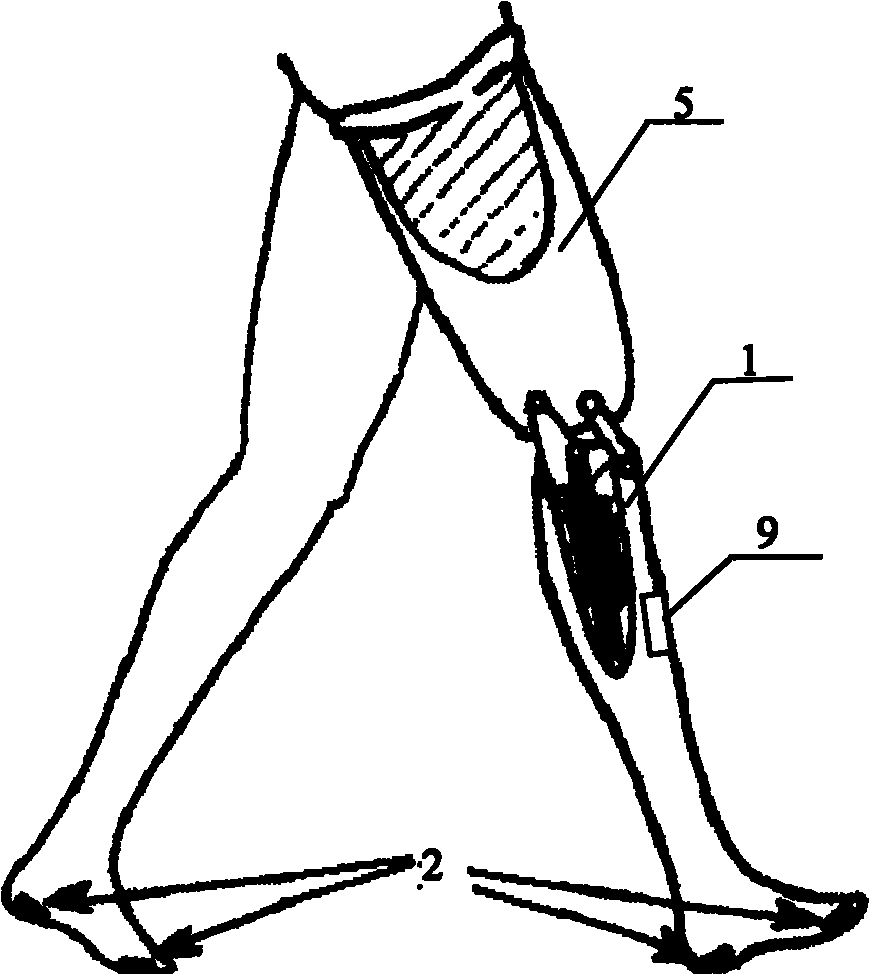

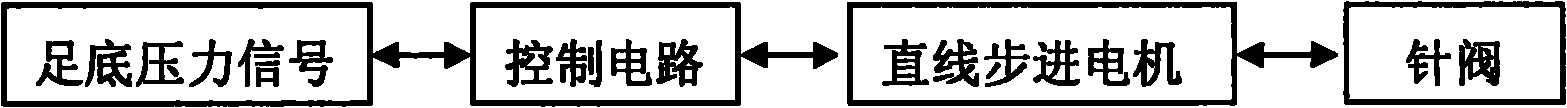

[0066] The installation of the used hardware part of the method for establishing the automatic training expert knowledge base of lower limb prosthesis:

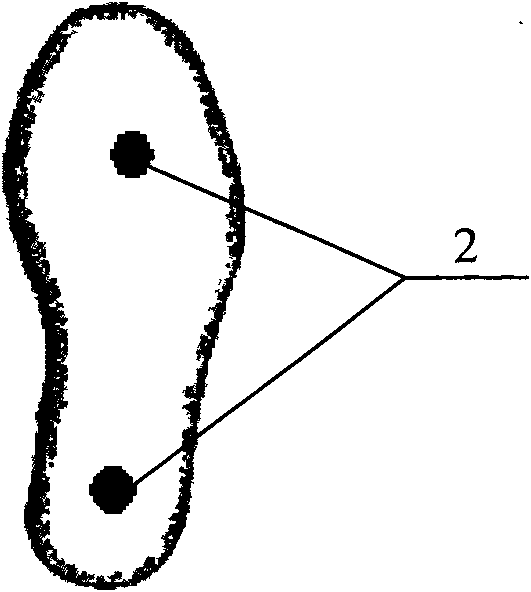

[0067] The hardware used includes a prosthetic knee joint 1, a socket 5, a plantar pressure sensor 2, a control device and a control circuit 9; the prosthetic knee joint 1 is a pneumatic lower limb prosthetic knee joint that can adjust bending and extension damping in a non-artificial manner, and is Installed in the lower part of the receiving cavity 5 worn by the thigh amputee; the control device is composed of a cylinder 6, a piston 7, a gas passage 8, a needle valve 3 and a linear stepper motor 4, and the piston 7 is installed in the cylinder 6, and the The cylinder 6 is divided into two chambers, and the two chambers are connected through the gas channel 8, the gas channel 8 is located outside the cylinder 6, the linear stepper motor 4 is installed at the bottom of the cylinder 6, and the needle valve 3 is installed on the...

Embodiment 2

[0070] The working process of the above-mentioned hardware part is: after installing all the above-mentioned hardware, let the subject walk normally. During the walking process, first detect the walking speed, and then determine the value of the angle of the knee joint from the ground at the current walking speed. When the knee joint angle When the angle of the knee joint is lifted off the ground, it is considered to have reached the swing period. The needle valve 3 in the above control device moves according to the corresponding opening value under the walking speed. When the knee joint is fully extended, it is considered to enter the support period. The needle valve 3 Keep it fully closed to maximize damping and increase stability during stances.

Embodiment 3

[0072] On the basis of embodiment 1 and embodiment 2, the collection and calculation of plantar pressure signal are carried out:

[0073] The analog-to-digital conversion module of the single-chip microcomputer in the control circuit 9, that is, the self-contained AD converter on the single-chip microcomputer, is collected and installed on the prosthesis side and the healthy limb side sole with a frequency of 500 times per second through the processing method of moving average filtering. The plantar voltage signal of the plantar pressure sensor 2, that is, the plantar pressure signal.

[0074] The calculation of the plantar pressure signal is completed by the single-chip microcomputer contained in the control circuit 9, and its calculation program can be divided into three parts according to the function:

[0075] The first part is the main program, which completes the initialization work after the system is powered on

[0076] Power on the system→turn off the watchdog→clock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com