Magnesium hydrate composition and manufacturing method thereof, and resin composition and molded article thereof

A magnesium hydroxide, manufacturing method technology, applied in the direction of magnesium hydroxide, dyed low-molecular organic compound treatment, fibrous filler, etc., can solve the problem of no improvement in flame retardancy, long-term water resistance of molded products, poor weather resistance, and environmental problems. Hormone pollution and other problems, to achieve the effect of excellent flame retardancy and durability, heat deterioration resistance and color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Add barium chloride corresponding to 90% of the molar number of sulfur remaining in the magnesium chloride solution 1 to the brine solution to precipitate barium sulfate, filter, concentrate or dilute, and adjust to a magnesium chloride solution with a Baume specific gravity of 1.3.

[0128] Add 5 L of the resulting solution into a 10 L autoclave, adjust the liquid temperature to 20° C., and add 5 L of milk of lime with a concentration of 12 wt % to adjust the liquid temperature to 20° C. over 5 minutes under agitation to make the magnesium chloride and calcium hydroxide Magnesium hydroxide particles were generated by the reaction, and the autoclave was heated while maintaining stirring after the addition of the milk of lime, and the temperature of the liquid in the autoclave was raised to 160° C. for 2.5 hours, and then maintained for 4 hours.

[0129] Afterwards, it is cooled by natural heat release, and the reaction suspension of the obtained magnesium hydroxide parti...

Embodiment 2~7

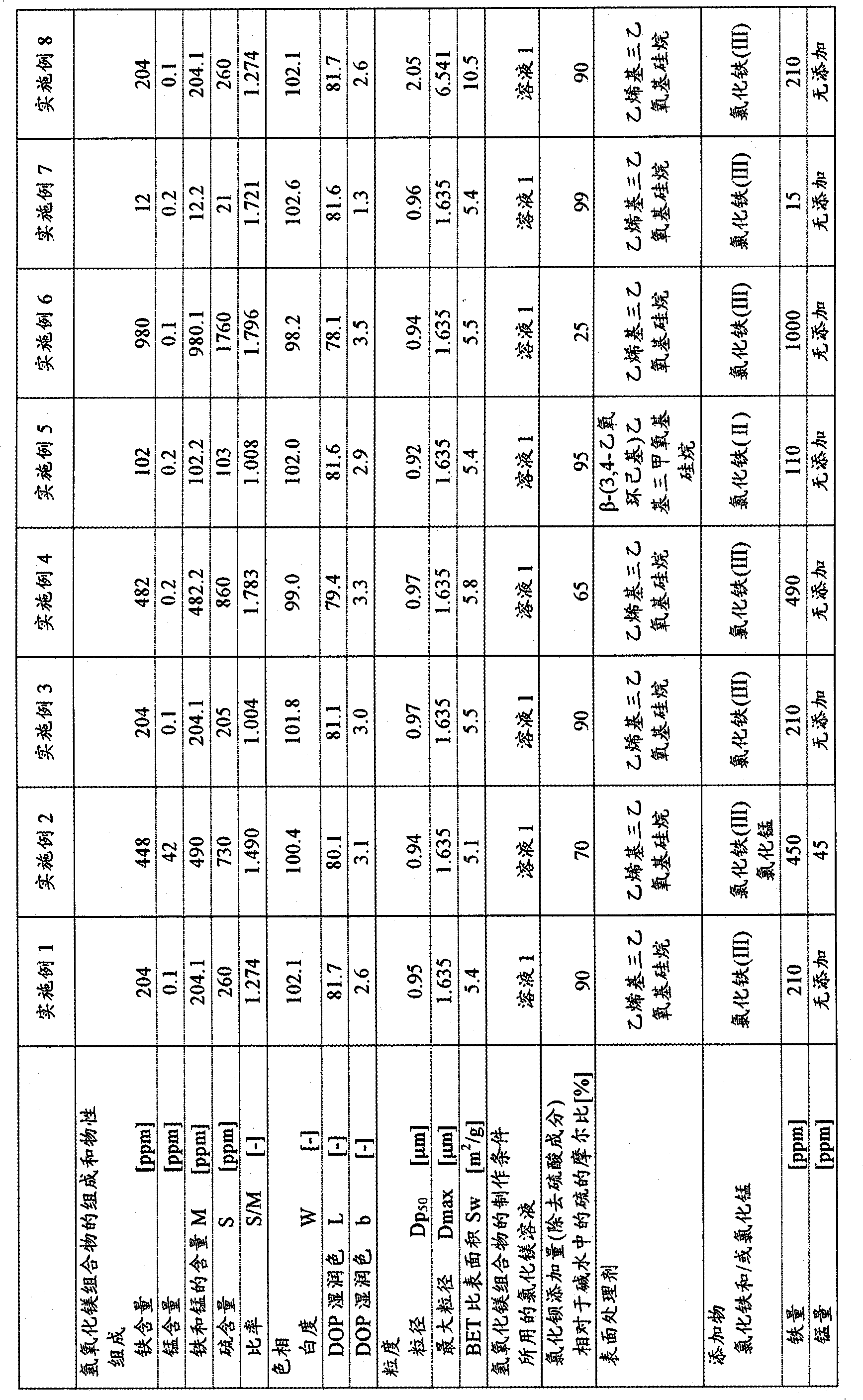

[0134] A magnesium hydroxide composition was prepared in the same manner as in Example 1 except that the conditions described in Table 1 were changed. The preparation conditions and various physical properties of the obtained magnesium hydroxide composition are shown in Table 1.

[0135] In Example 2, iron (III) chloride corresponding to 450 ppm of iron and manganese chloride corresponding to 45 ppm of manganese were added.

Embodiment 8

[0137] A magnesium hydroxide composition was prepared in the same manner as in Example 1, except that the time for putting milk of lime into the magnesium chloride solution in the autoclave was changed to 12 minutes. The preparation conditions and various physical properties of the obtained magnesium hydroxide composition are shown in Table 1.

[0138] [Table 1]

[0139]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com