Polyvinyl chloride resin composition and method for producing the same

A technology of polyvinyl chloride resin and manufacturing method, which is applied in the field of polyvinyl chloride resin composition, can solve the problems of insufficient thermal stability, coloring, etc., and achieve the effect of less coloring and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] (Manufacture of polyvinyl chloride resin)

[0107] Polyvinyl alcohol with a polymerization degree of 850 and a saponification degree of 72 mol% was dissolved in deionized water in an amount equivalent to 600 ppm with respect to vinyl chloride to produce a dispersion stabilizer. The dispersion stabilizer thus obtained was put into a glass-lined autoclave coated with an antifouling agent NOXOL WSW (manufactured by CIRS Corporation) so that the solid content was 0.3 g / m. 2 . Next, 0.04 parts of a 70% toluene solution of diisopropyl percarbonate was added to a glass-lined autoclave, the pressure in the autoclave was exhausted to 0.0067 MPa, and oxygen was removed, then 30 parts of vinyl chloride were added, and the high-pressure The temperature of the contents in the kettle was raised to 57°C, and polymerization was initiated with stirring. The pressure in the autoclave at the start of polymerization was 0.83 MPa. After starting the polymerization, 7 hours later, the pol...

Embodiment 2

[0118] In Example 1, during polymerization, the monomer having a polyoxyalkylene group was changed to polyoxyethylene methacrylamide (n=10), the added weight of vinyl acetate and methanol was changed, and the molar ratio of alkali was changed during saponification, Other than that, POA-modified PVA shown in Table 1 was obtained by the same method. Evaluation of thermal stability and colorability was carried out in the same manner as in Example 1. The evaluation results are shown in Table 1.

Embodiment 3

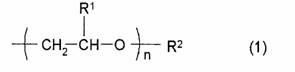

[0120] In Example 1, during polymerization, the monomer having a polyoxyalkylene group was changed to polyoxyethylene polyoxybutylene methacrylamide (corresponding to R in the general formula (3). 1 is an alkyl group with 2 carbon atoms, R 2 is a hydrogen atom, R 3 is a hydrogen atom, R 4 is methyl, R 5 is a hydrogen atom, R 6 is hydrogen atom, X is -CONH-, m=2, n=10), change the added weight of vinyl acetate and methanol, change the alkali molar ratio during saponification, in addition, follow the same method to obtain as shown in Table 1 POA modified PVA. Evaluation of thermal stability and colorability was carried out in the same manner as in Example 1. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com