Cluster jet processing method, semiconductor element, microelectromechanical element, and optical component

A processing method and jet-type technology, applied in semiconductor/solid-state device manufacturing, optics, electrical components, etc., can solve the problems of inapplicable miniaturization and high-density patterns, and achieve the effect of improving progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

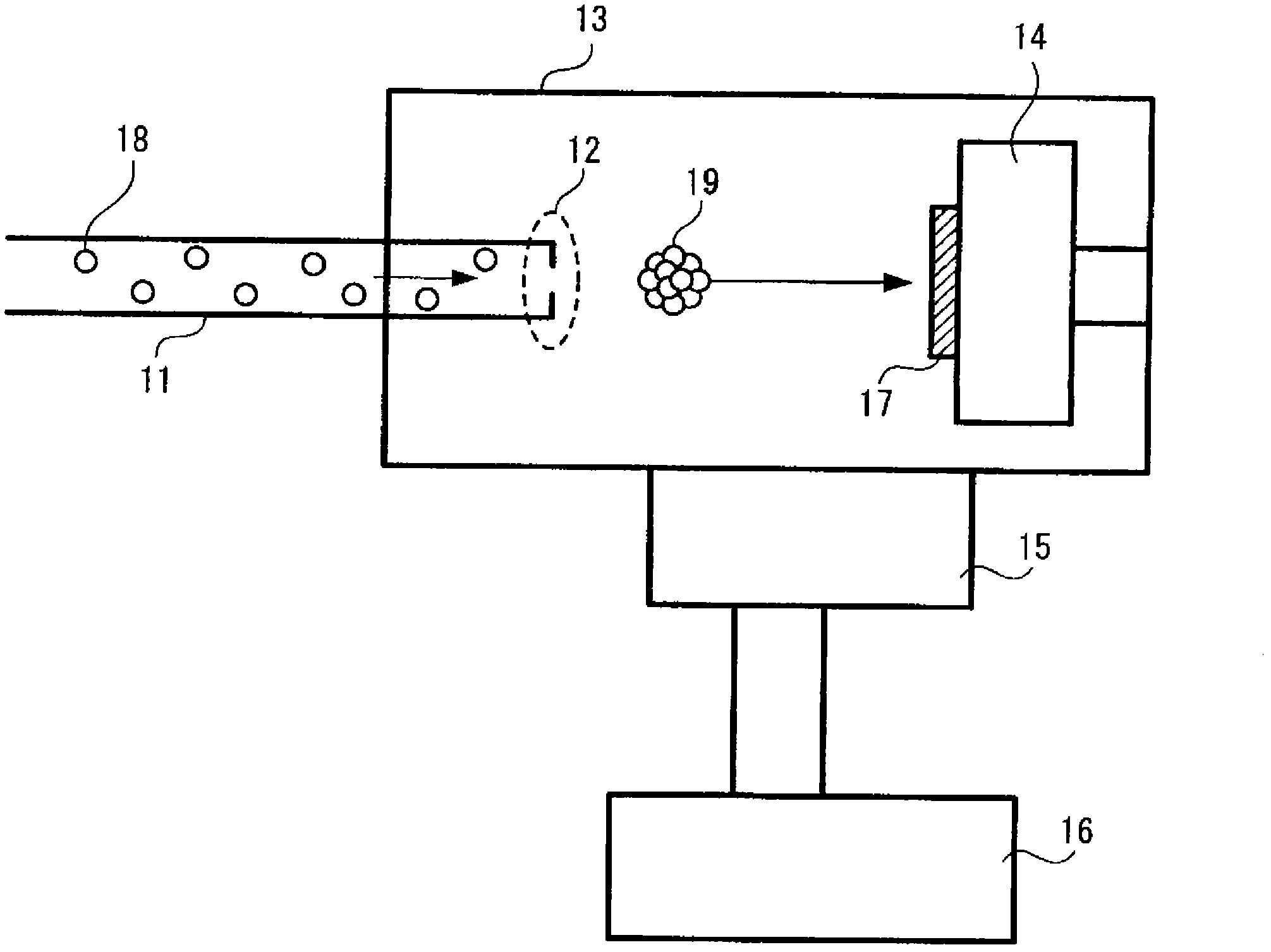

[0127] Next, the results of actually processing the sample using the cluster spraying processing method of the present embodiment are shown as follows:

[0128] First, the injection time of the mixed gas sprayed on the sample and the primary pressure of the mixed gas in the gas supply unit are changed to process the surface of the sample. The relationship between the primary pressure of the process and the injection time of the sample sprayed on the sample and the etching rate of the sample is as follows: figure 2 shown.

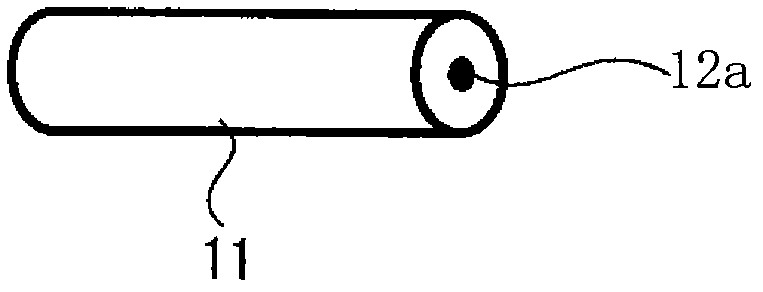

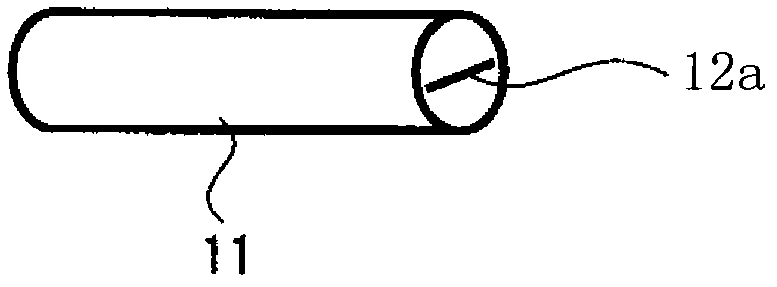

[0129] The processing conditions are as follows: a silicon single crystal having a natural oxide film with a thickness of about 2 nm formed on the surface is used as a sample, and 6 vol% of ClF is used as a reactive gas. 3 Gas and a mixed gas composed of 94 vol % Ar gas which is a gas having a boiling point lower than that of the reactive gas. In addition, the diameter of the discharge part was set to 0.1 mm. Alternatively, make a pressure such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com