Suction nozzle of sheet adhesive machine

A technology of placement machine and nozzle head is applied in the direction of electrical components, electrical components, and electrical components to assemble printed circuits, which can solve the problems of increasing production costs, easy accumulation of static electricity, and high conductivity of metal materials, and achieves good thermoplastic processing. performance, good dispersibility of pigments, and the effect of not easily accumulating static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

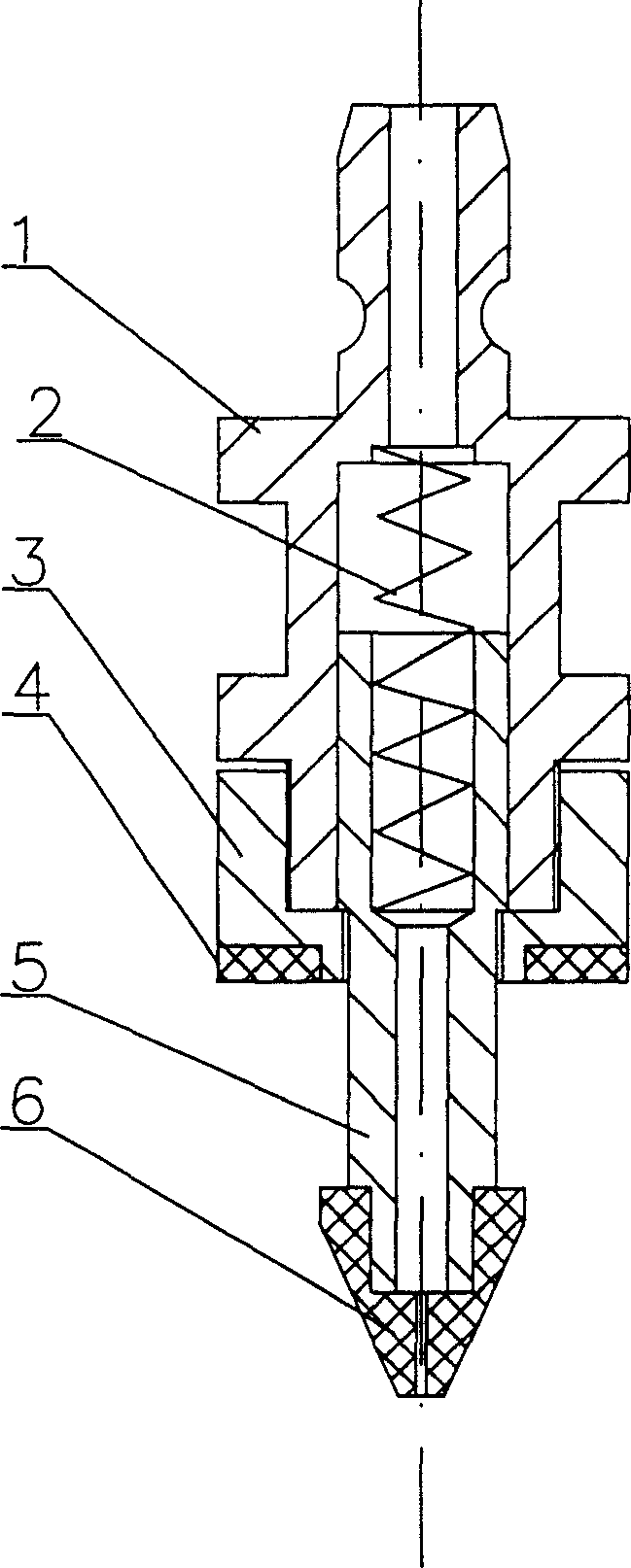

[0023] Such as figure 1 Shown: a suction nozzle of a placement machine of the present invention, the suction nozzle includes a suction nozzle seat 1 and a light-shielding seat 3 threaded therewith, a suction nozzle head 5 and a buffer spring 2, etc., wherein the outer diameter of the suction nozzle head 5 is the same as The inner diameter of the nozzle seat 1 is in an airtight transition fit state; the nozzle head 5 is composed of an upper metal substrate and a lower tapered nozzle mouth 6, and the tapered nozzle mouth 6 is mainly used for pasting It absorbs small parts; the light-shielding seat 3 is composed of the upper metal base and the lower light-shielding layer 4; the tapered suction nozzle 6 and the light-shielding layer 4 are both dark black on the surface and the body Made of Delrin plastic.

[0024] The molecule of the polyoxymethylene is a highly regular oxidized methine (-CH 2 O-) unit groups are polymerized, and the polyoxymethylene molecules have a high degree...

Embodiment 2

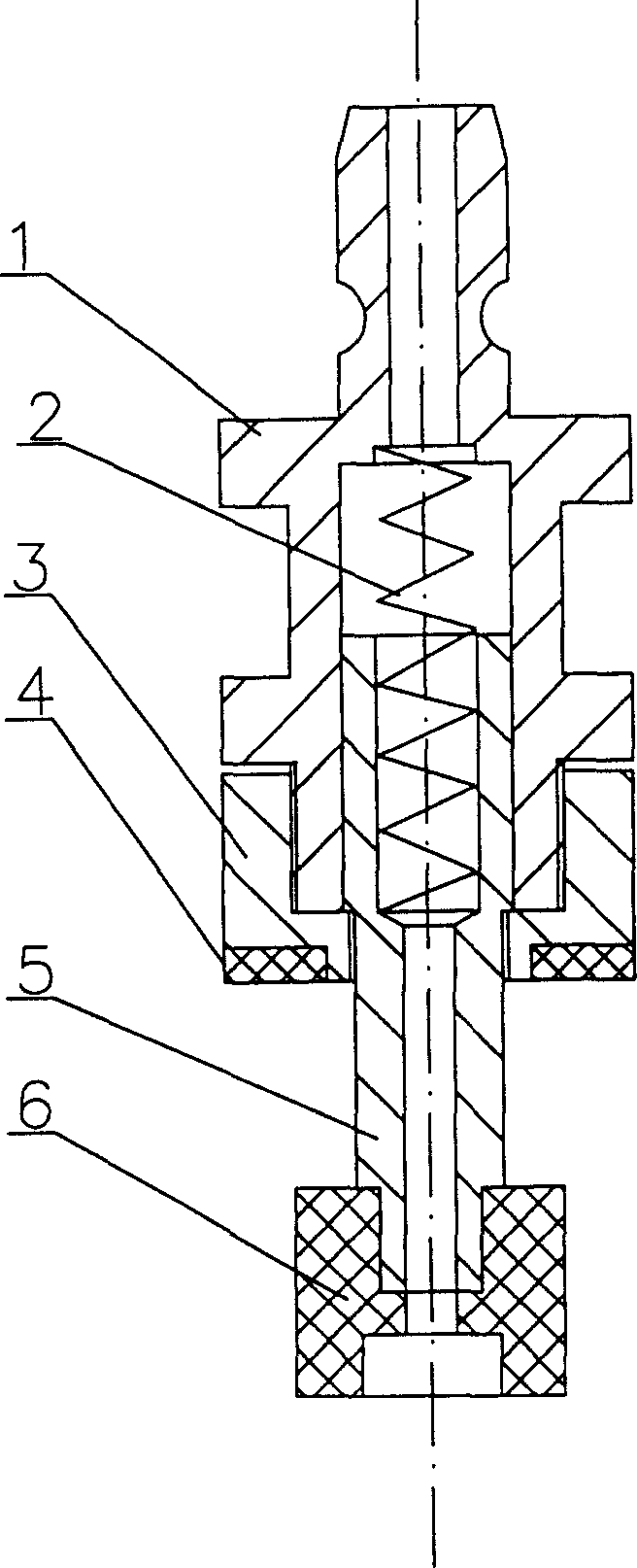

[0028] Such as figure 2 Shown: a suction nozzle of a placement machine of the present invention, the suction nozzle includes a suction nozzle seat 1 and a light-shielding seat 3 threaded therewith, a suction nozzle head 5 and a buffer spring 2, etc., wherein the outer diameter of the suction nozzle head 5 is the same as The inner diameter of the nozzle seat 1 is in an airtight transition fit state; the nozzle head 5 is composed of an upper metal substrate and a lower diameter-expanding nozzle mouth 6, and the diameter-expanding nozzle mouth 6 is mainly used for sticking Suction chips and other large-area spare parts; the shading seat 3 is composed of the upper metal base and the lower shading layer 4; They are all made of dark green polyoxymethylene plastic.

[0029] The molecule of the polyoxymethylene is a highly regular oxidized methine (-CH 2 O-) unit groups are polymerized, and the polyoxymethylene molecules also have a high degree of crystallinity.

[0030] The sucti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com