Method for realizing high-stereoselectivity synthesis of Toremifene by configuration conversion method

A technology of stereoselectivity and toremifene, applied in the field of medicine and chemical industry, achieves the effects of high stereoselectivity, high reaction yield and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

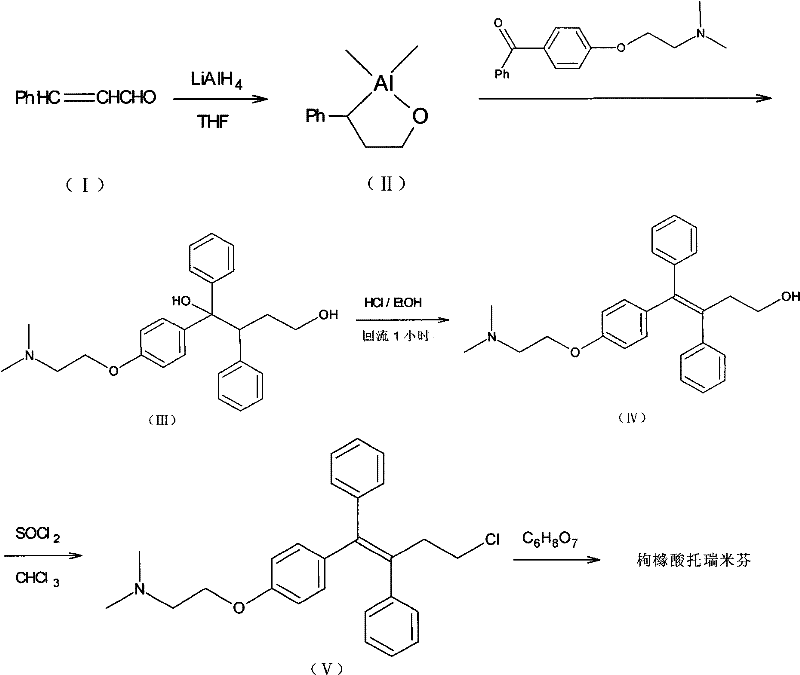

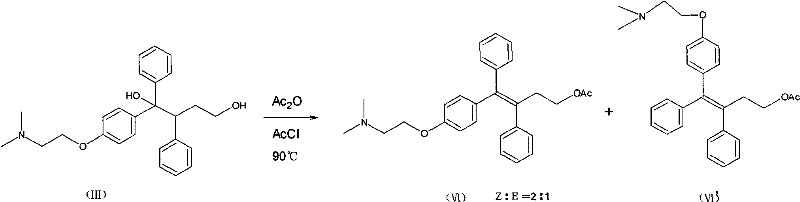

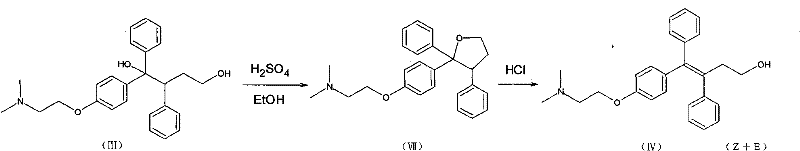

Method used

Image

Examples

example 1

[0034] 8.10 g (20 mmol) of triarylbutanediol was suspended in 80 ml of concentrated hydrochloric acid, heated to 65° C., and the solid was completely dissolved, and stirring was continued for 2 hours. TLC (silica gel plate, CH 2 Cl 2 : CH 3 OH=9:1 development, UV detection) showed that the triarylbutanediol had disappeared and three spots mainly appeared. Rf0.75, accounting for about 5%, is the cyclization product (VII), Rf0.60, accounting for about 10%, is Z-type triarylbutenol; Rf0.50, accounting for about 85%, is E-type triaryl butenol.

[0035] The above mixture was gradually cooled to 40°C, and under vigorous stirring and induced by seed crystals, the reaction mixture began to become mixed and a solid precipitated. After 10 hours a large amount of solid precipitated out. TLC detection of the precipitated solid showed only the point of Rf 0.60, indicating that it was Z-type triarylbutenol hydrochloride. The TLC in the solution shows that there are almost no cyclizati...

example 2

[0038] Suspend 8.10 g (20 mmol) of triaryl butanediol in 80 ml of concentrated hydrochloric acid, stir at room temperature for 1 hour, then stir at 35°C for 15 hours, then cool to 10°C and stir for more than 2 hours, collect the resulting solid by filtration, and Suspend it in 150ml toluene, alkalinize carefully with 100ml 10% aqueous sodium hydroxide solution, separate the water layer and wash with 2×25ml water, dry over anhydrous sodium sulfate, filter and concentrate to a total volume of about 30ml, 0~5℃ After standing overnight, the precipitated white solid was collected and air-dried to obtain 6.8 g of white solid, m.p.119°C, yield 89%. The purity was 99% by HPLC.

example 3

[0040] Suspend 8.10g (20mmol) of triarylbutanediol in 40ml of concentrated hydrochloric acid, stir at room temperature for 1 hour, then stir at 35°C for 3 hours, then stir at 45°C for 7 hours, add 40ml of water to dilute for filtration, and then cool to 10°C Stir for 2 hours. By the same operation as above, 6.5 g of Z-type triaryl butenol was obtained, with a yield of 84%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com