Method for preparing overlarge crystal-cell porous pellumina

A porous alumina and unit cell technology, applied in the field of nano-scale physical material preparation, can solve the problems of low environmental temperature requirements, difficult quality assurance, complicated preparation process, etc., and achieve the effect of high flash fire voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

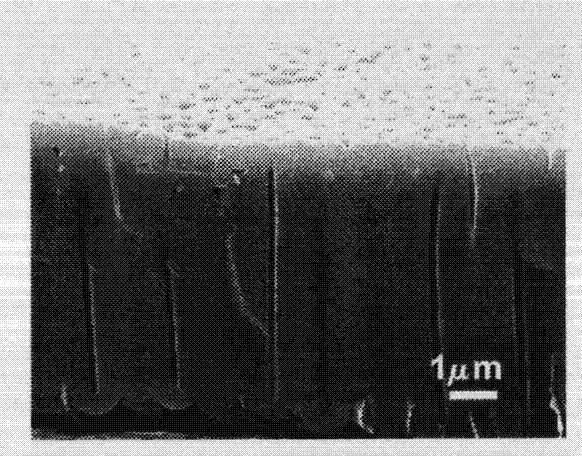

[0013] The electrolyte composition is selected as a volume ratio of citric acid aqueous solution to ethylene glycol of 2:1, wherein the weight percentage concentration of the citric acid aqueous solution is 2%, the temperature is 20°C, the primary anodic oxidation voltage is 390V, and the time is 20 hours; figure 1 The scanning electron micrograph of the porous alumina film prepared for this example shows that the unit cell pores of the porous alumina are about 900 nm.

Embodiment 2

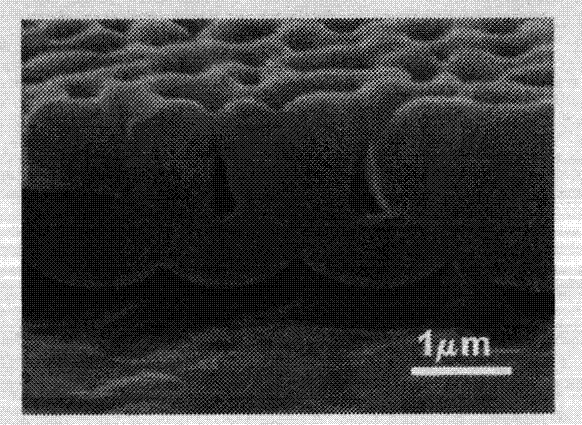

[0015] The electrolytic solution is selected to be composed of citric acid aqueous solution and ethylene glycol volume ratio of 2:1, wherein the weight percent concentration of citric acid aqueous solution is 2%, the temperature is 10°C, the primary anodic oxidation voltage is 600V, and the time is 11.5 hours; in the mixed acid solution After removing the aluminum oxide produced in the first anodization, the conditions of the second anodization are the same as the first time, and the time is 2 hours; figure 2 The scanning electron micrograph of the porous alumina membrane prepared for this example shows that the unit cell of the porous alumina is about 1.5 μm.

Embodiment 3

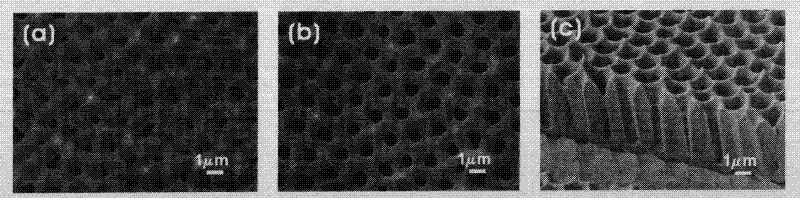

[0017] The electrolytic solution is selected to be composed of citric acid aqueous solution and ethylene glycol volume ratio of 1:2, wherein the weight percent concentration of citric acid aqueous solution is 1%, the temperature is 13°C, the primary anodic oxidation voltage is 700V, and the time is 15.5 hours; the mixed acid solution removes After anodizing the alumina generated in the first anodization, the conditions of the second anodization are the same as the first time, and the time is 2 hours; image 3 The scanning electron micrograph of the porous aluminum oxide membrane prepared for the present embodiment, image 3 a The unit cell of porous alumina is about 1.8 μm, and the pore diameter is about 300nm; in order to obtain a porous membrane with a larger pore size, it can be chemically etched in a phosphoric acid solution with a concentration of 5% by weight at 53°C for 20 minutes, and the pore size is expanded to about 800nm ,Such as image 3 As shown in a and b, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| unit cell | aaaaa | aaaaa |

| unit cell | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com