Non-intrusive flow measuring device for industrial gas pipeline

A flow measurement device and industrial gas technology, applied in the application of thermal effects to detect fluid flow, etc., can solve the problems of difficult gas measurement, lack of mature technology and products, etc., achieve convenient and fast flow monitoring, avoid unnecessary losses, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

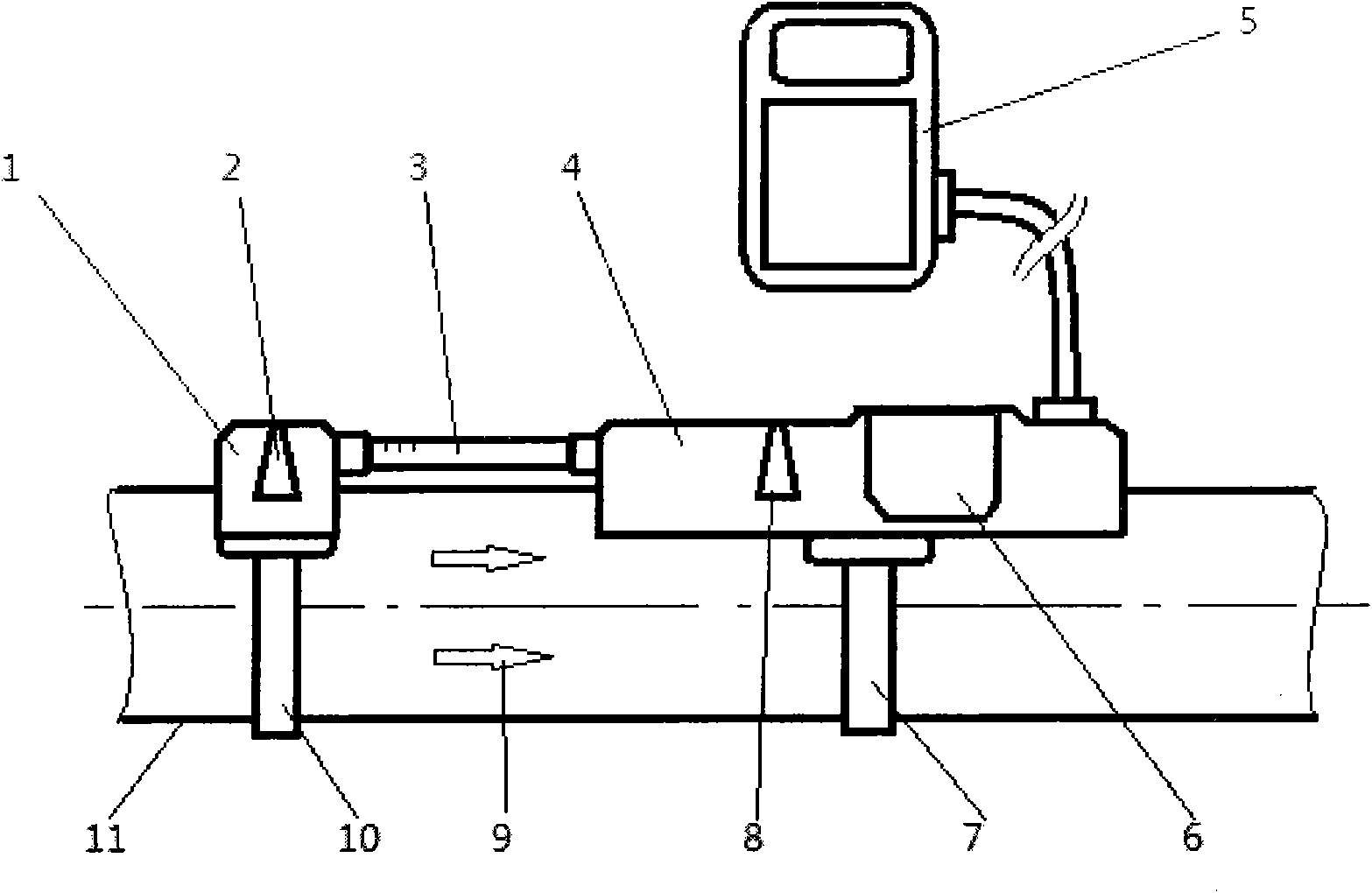

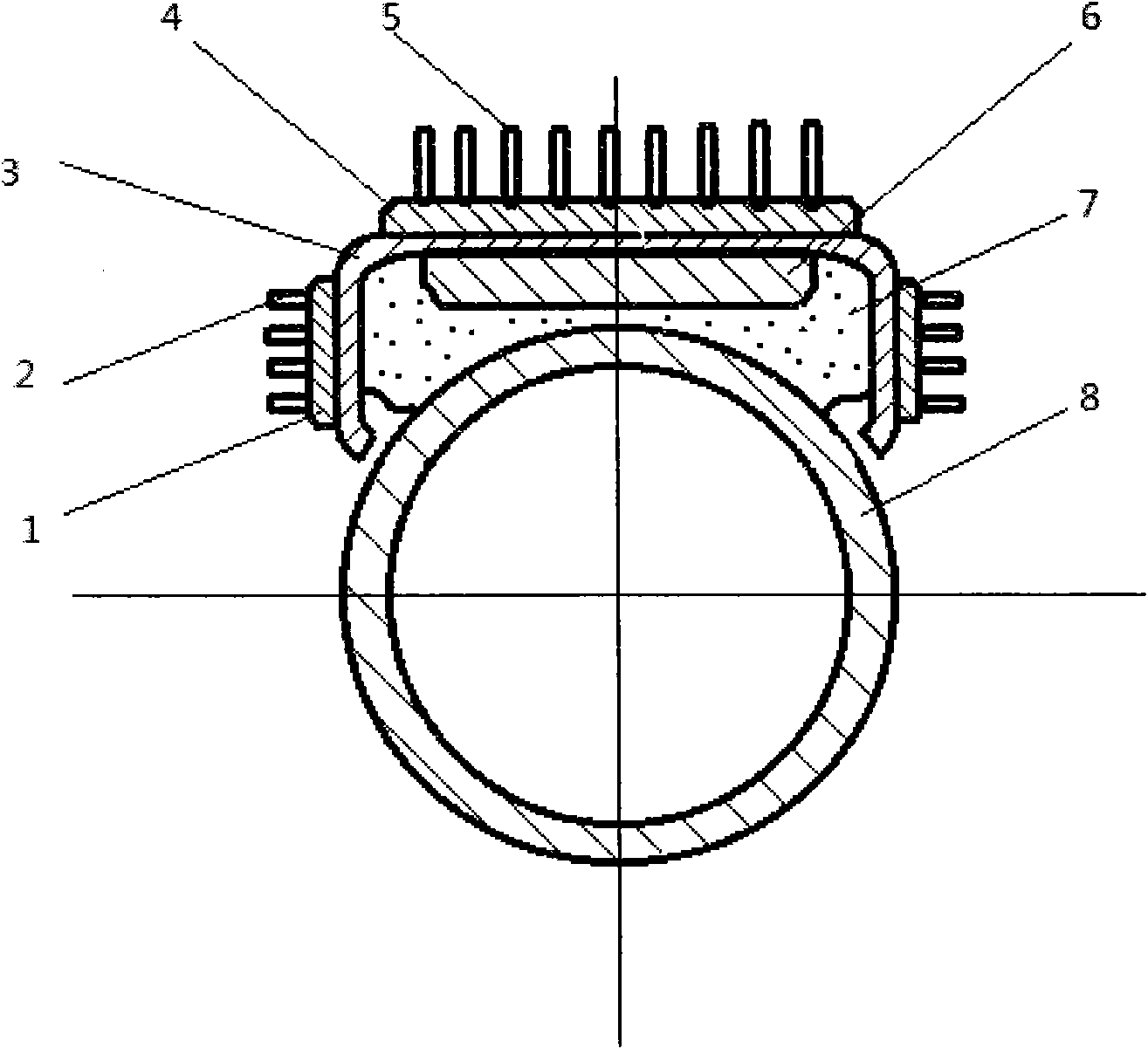

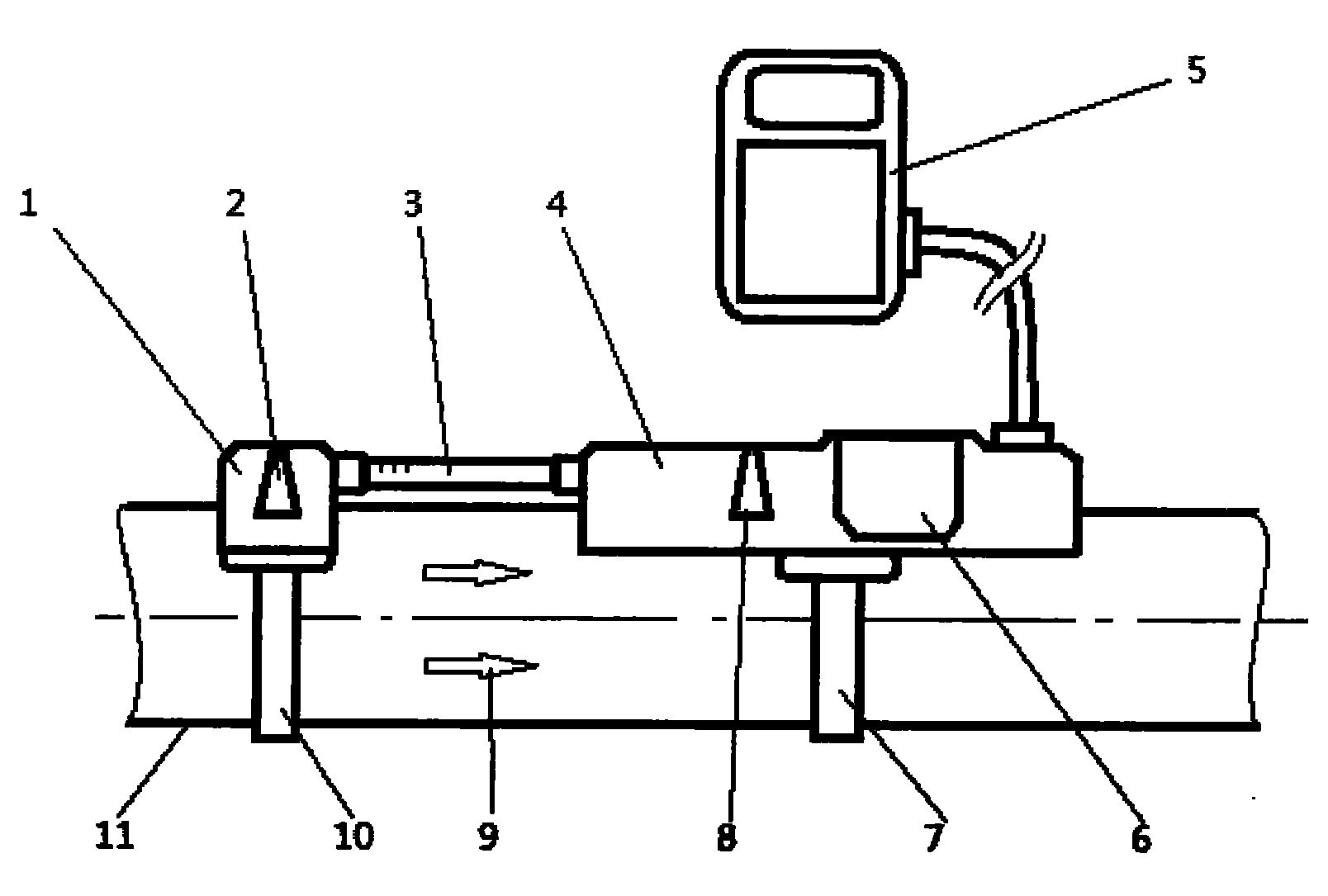

[0022] exist figure 1 Among them, the equipment main body 4 and the equipment auxiliary body 1 have been installed on the pipe 11 as required, the restraint devices 7 and 10 make the equipment close to the pipe wall, and the heat pulse generating device 6 sends out heat pulses as required, and the pulse runs along the pipe wall against The direction of the airflow propagates upstream. The closer downstream temperature sensor 8 first measures the heat pulse, and then the farther upstream temperature sensor 2 measures the pulse. Due to the influence of distance and gas flow heat dissipation, the temperatures measured by the two sensors There is a time difference in the signal, and the host 5 converts the time difference and corrects it with reference to the existing data to obtain the actual gas flow and display it. exist figure 2 Among them, the U-shaped aluminum alloy frame 3 is designed so that the thermal pulse generating device can be attached to the outer wall of the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com