Step-like groove-grid high electron mobility transistor

A high electron mobility, transistor technology, applied in the field of microelectronics, can solve the problems of complex transistor fabrication process and increase the difficulty of devices, and achieve the effect of reducing source-drain contact resistance, improving device performance, and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

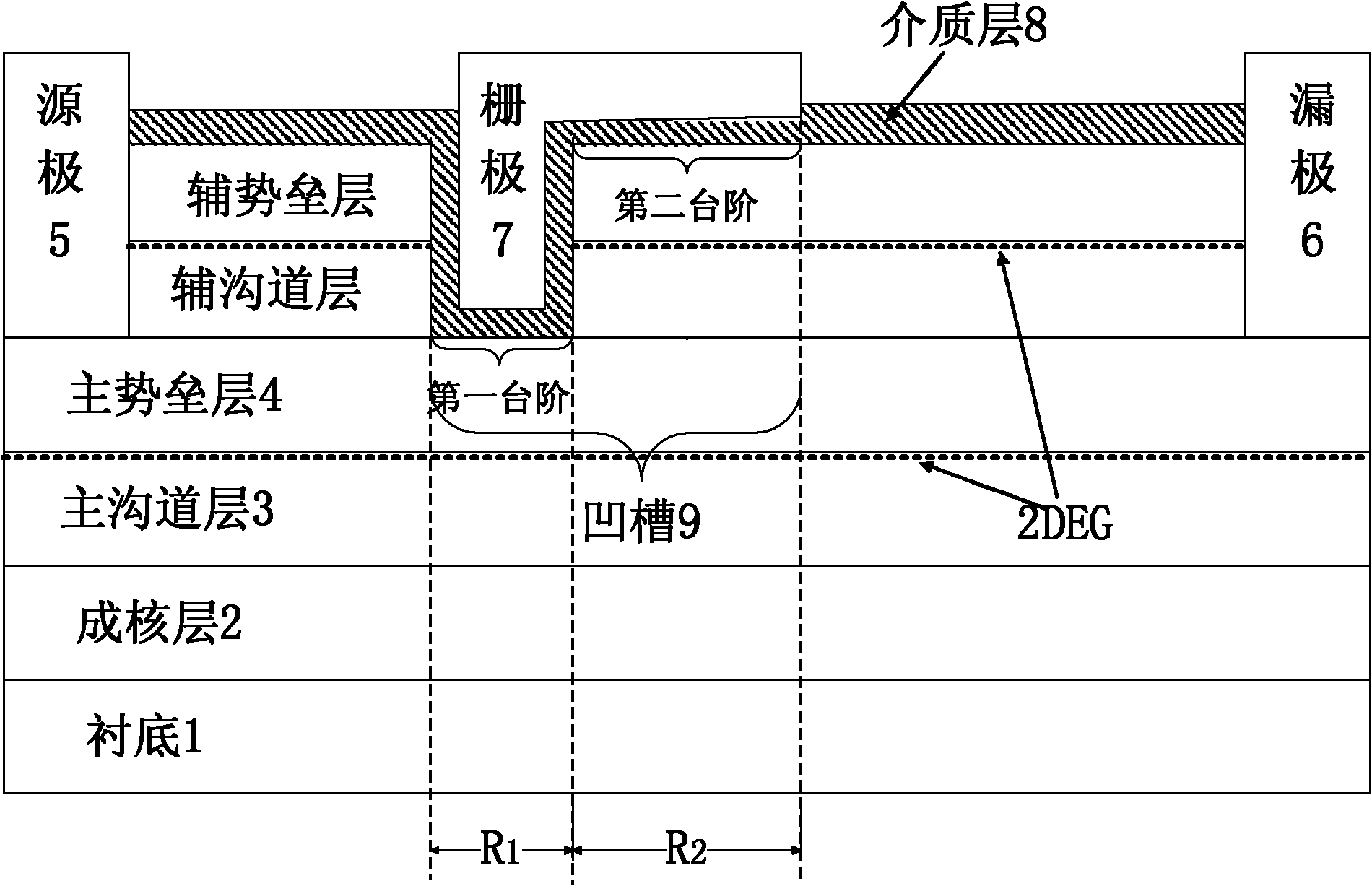

[0041] see figure 1 , the structure of the step type groove gate high electron mobility transistor HEMT of the present invention is: above the substrate 1 is the nucleation layer 2; above the nucleation layer 2 is the main channel layer 3; above the main channel layer 3 is the main potential Barrier layer 4, a two-dimensional electron gas 2DEG is formed on the interface between the main channel layer 3 and the main barrier layer 4; the source electrode 5 and the drain electrode 6 are on both sides of the top of the main barrier layer 4, and the gate 7 is in the middle; An auxiliary channel layer and an auxiliary barrier layer are sequentially added to the barrier layer 4, and 2DEG is formed on the interface between the auxiliary channel layer and the auxiliary barrier layer; a dielectric layer 8 is arranged above the auxiliary barrier layer; the auxiliary barrier layer There is a groove 9 between the main barrier layer 4, the depth of the groove decreases stepwise, the first s...

Embodiment 2

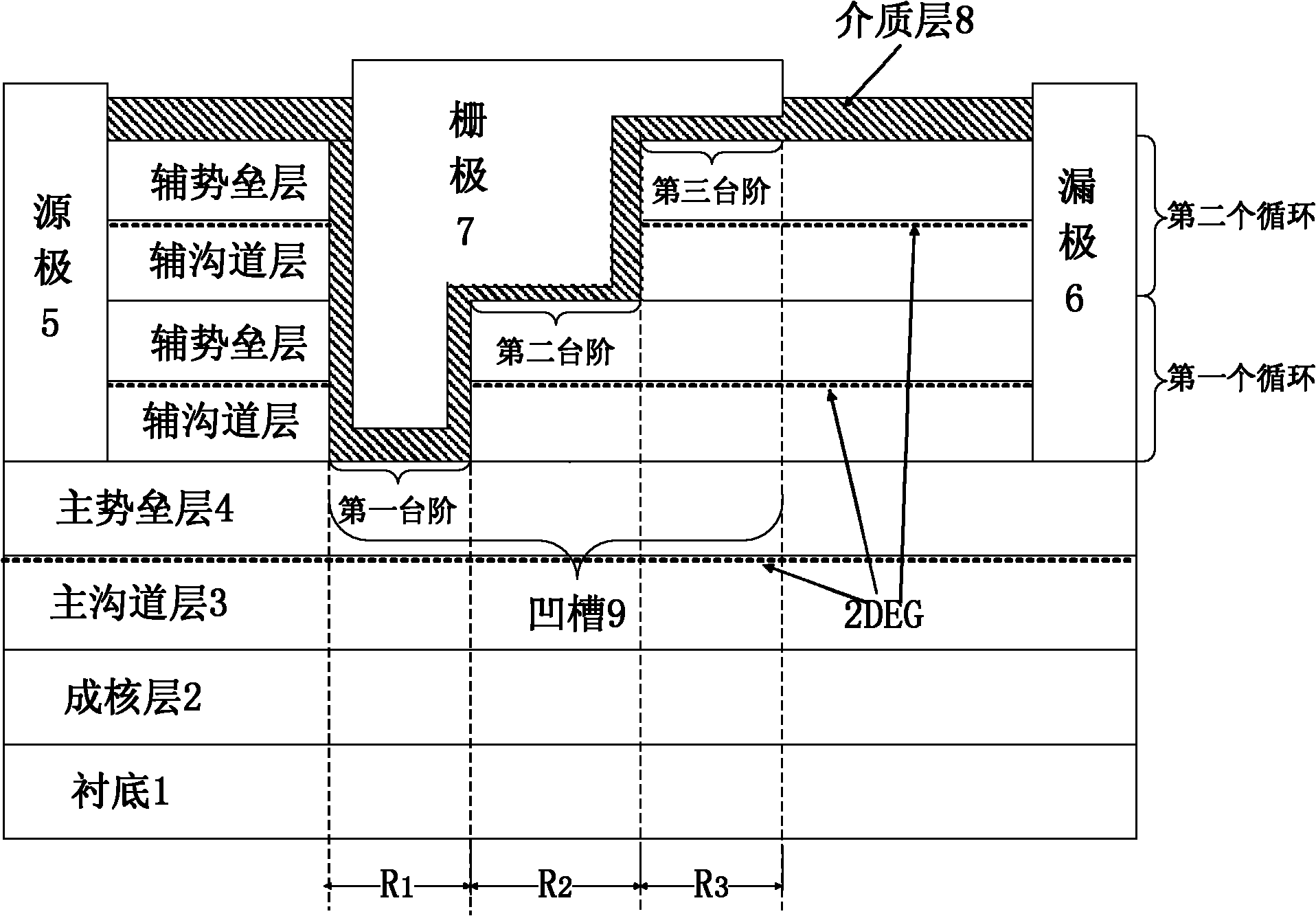

[0043] see figure 2 , the structure of the step type groove gate high electron mobility transistor HEMT of the present invention is: above the substrate 1 is the nucleation layer 2; above the nucleation layer 2 is the main channel layer 3; above the main channel layer 3 is the main potential Barrier layer 4, a two-dimensional electron gas 2DEG is formed on the interface between the main channel layer 3 and the main barrier layer 4; the source electrode 5 and the drain electrode 6 are on both sides of the top of the main barrier layer 4, and the gate 7 is in the middle; The barrier layer 4 is sequentially increased with an alternating cycle heterostructure composed of two auxiliary channel layers and auxiliary barrier layers, wherein a 2DEG is formed on the interface between each auxiliary channel layer and the auxiliary barrier layer immediately above it. ; There is a dielectric layer 8 above the top auxiliary barrier layer; a groove 9 is provided between the auxiliary barrie...

Embodiment 3

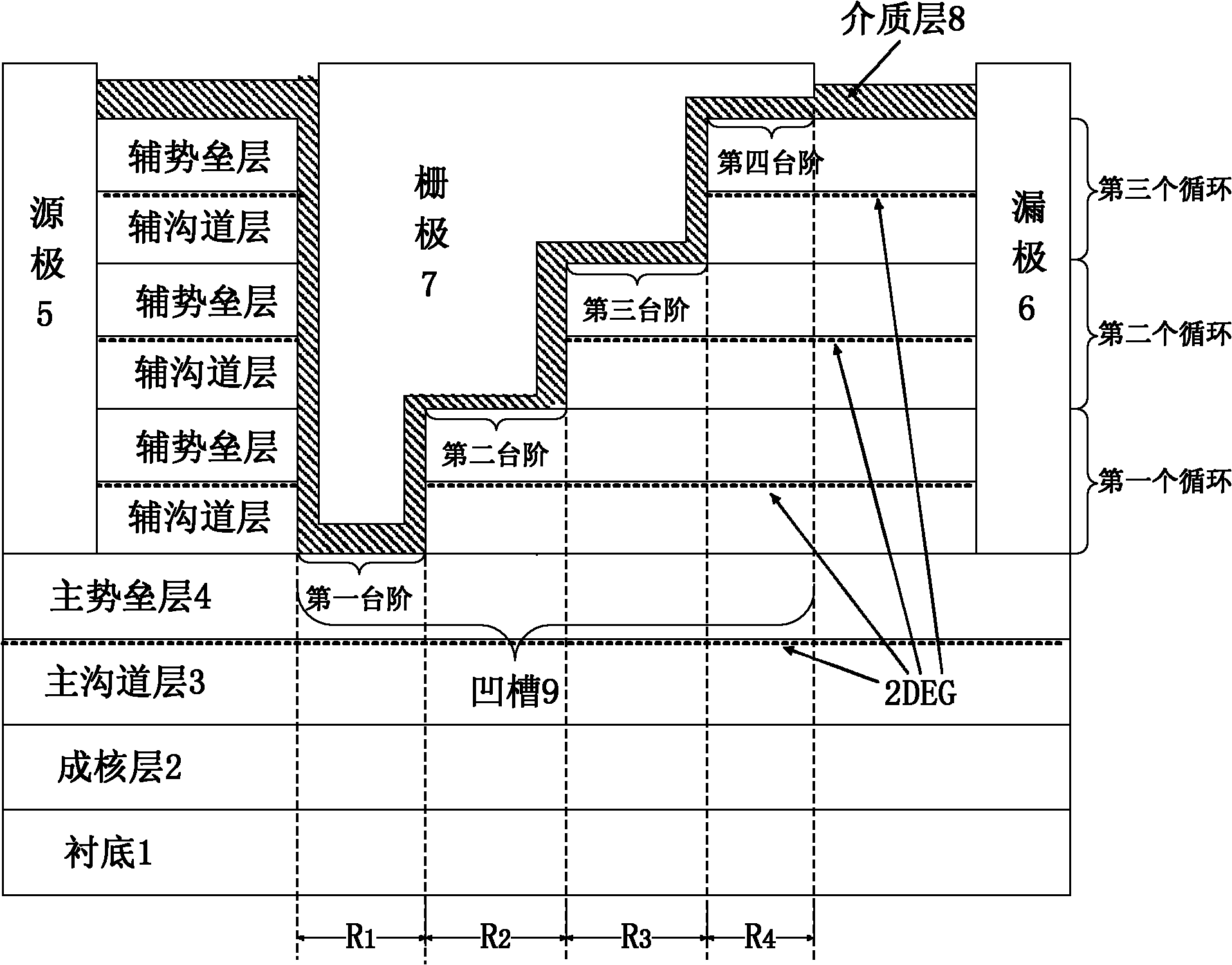

[0045] see image 3 , the structure of the step type groove gate high electron mobility transistor HEMT of the present invention is: above the substrate 1 is the nucleation layer 2; above the nucleation layer 2 is the main channel layer 3; above the main channel layer 3 is the main potential Barrier layer 4, a two-dimensional electron gas 2DEG is formed on the interface between the main channel layer 3 and the main barrier layer 4; the source electrode 5 and the drain electrode 6 are on both sides of the top of the main barrier layer 4, and the gate 7 is in the middle; An alternating cycle heterostructure composed of three auxiliary channel layers and auxiliary barrier layers is sequentially added to the barrier layer 4, wherein 2DEG is formed on the interface between each auxiliary channel layer and the auxiliary barrier layer immediately above it; There is a dielectric layer 8 above the top auxiliary barrier layer; a groove 9 is provided between the auxiliary barrier layer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com