Method for improving osmotic dehydration rate by changing carrot osmotic dehydration balance through ultrasonic field

A technology of osmotic dehydration and carrots, applied in the direction of preservation of fruits/vegetables through dehydration, etc., can solve problems such as lack of experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

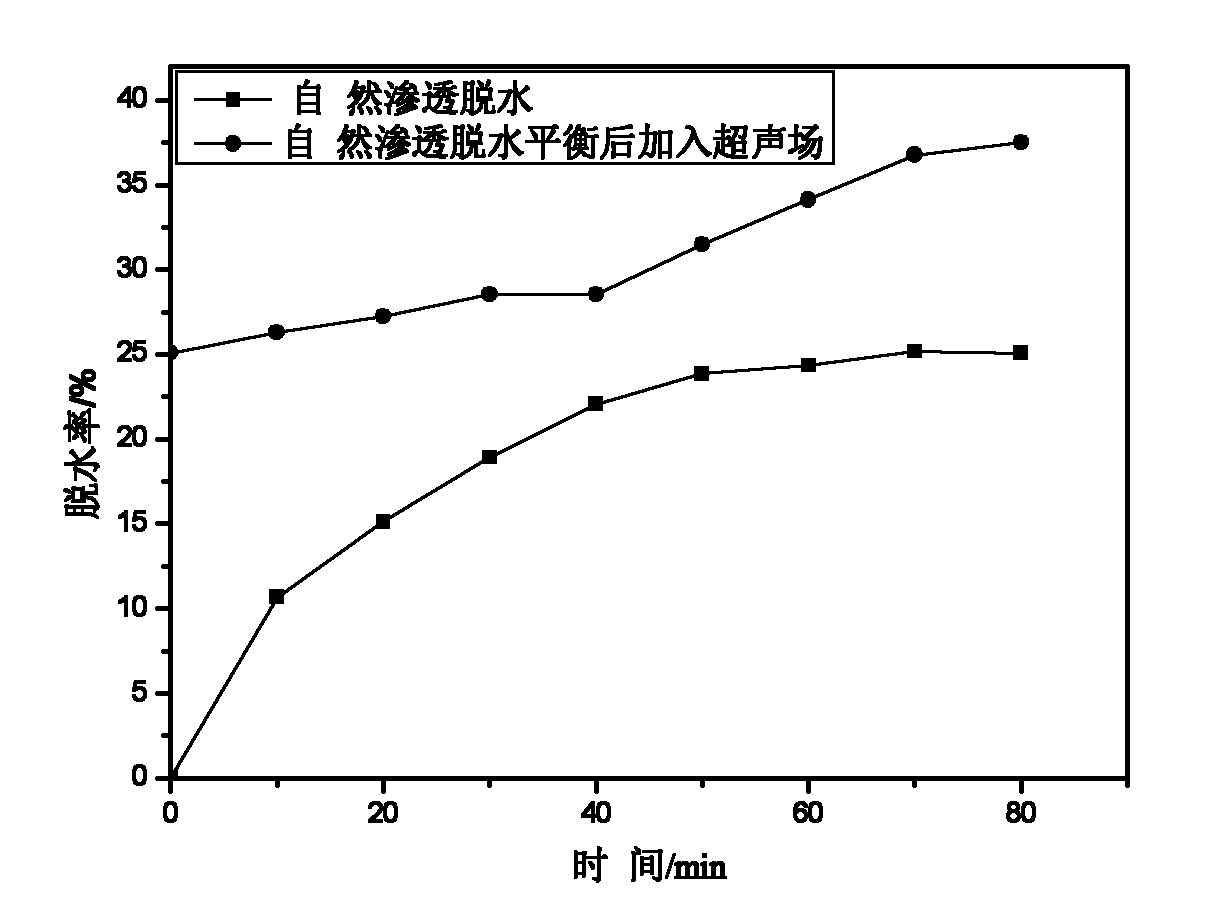

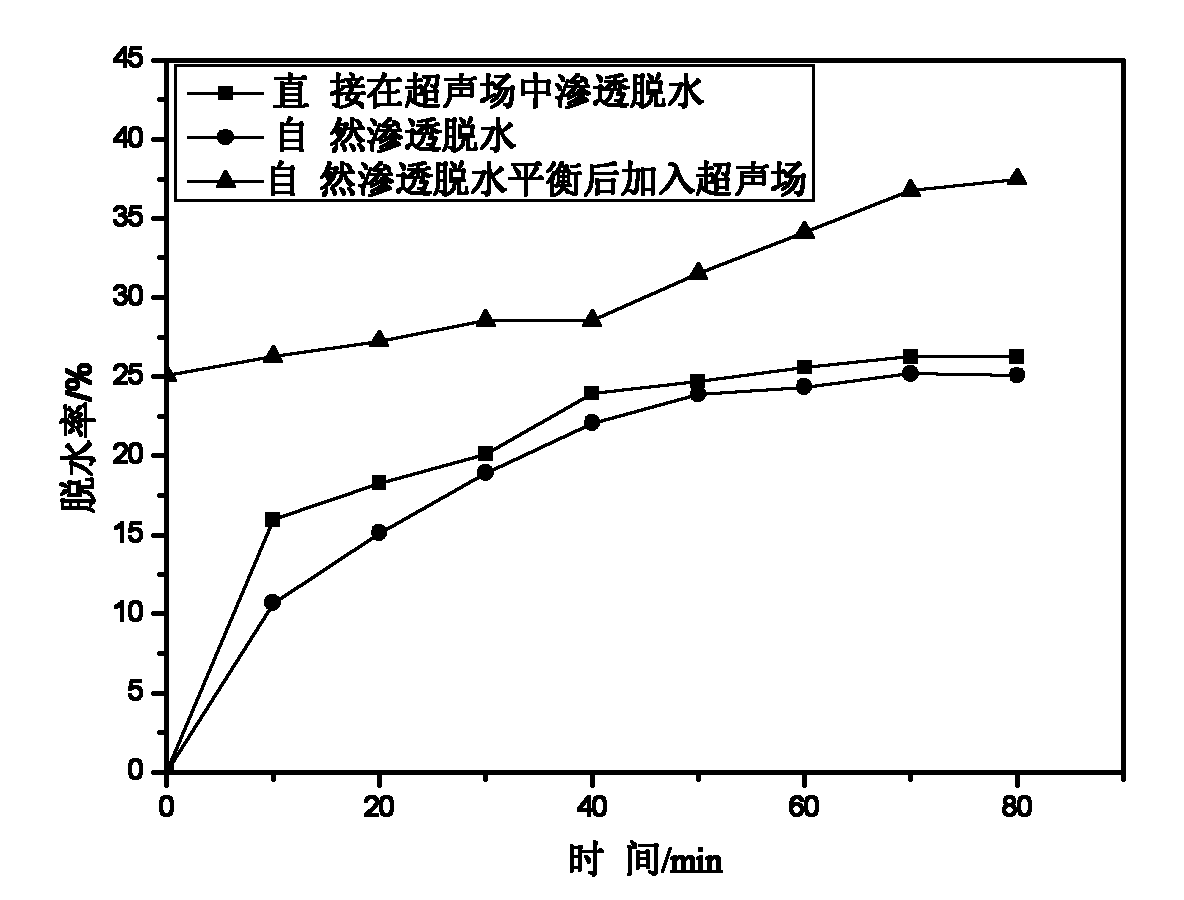

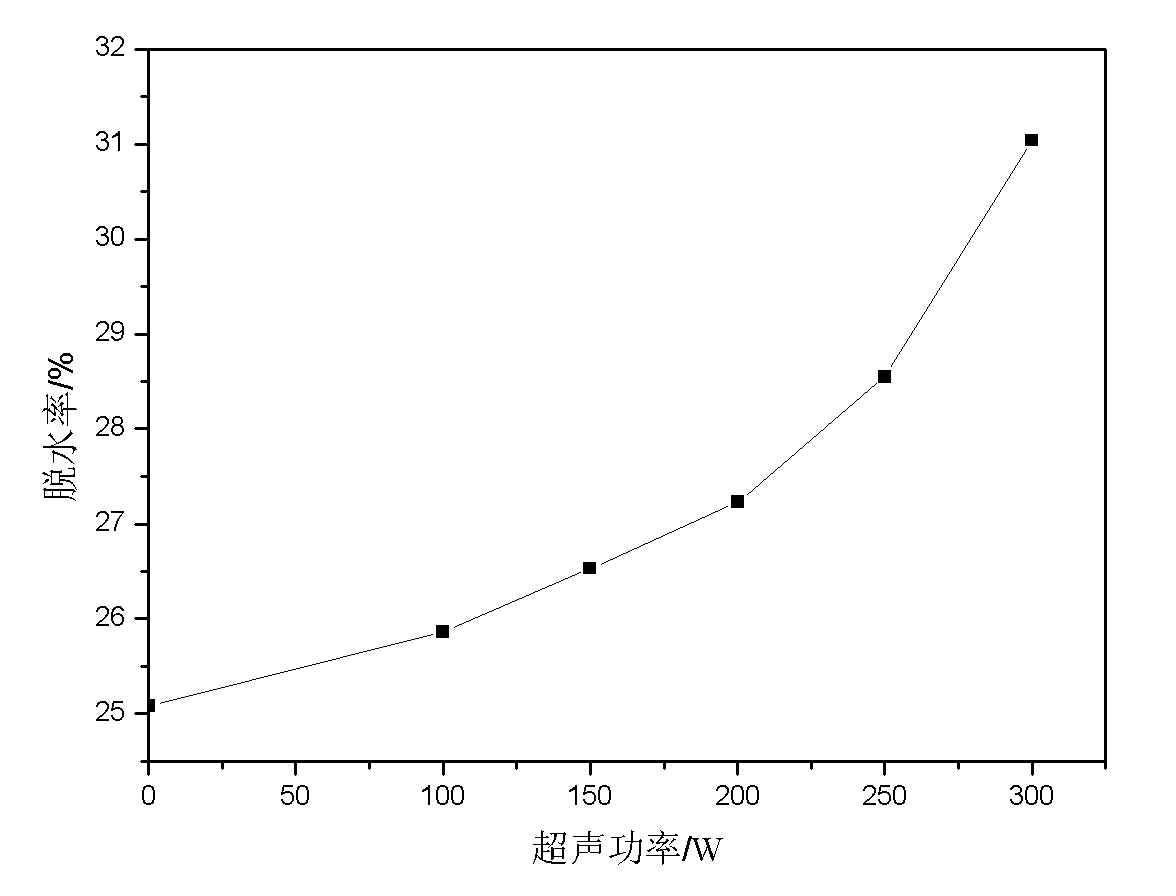

[0013] Implementation method: put 10g of peeled fresh carrot slices with a size of 1cm×1cm×1cm into 100g of sucrose solution with a mass fraction of 30%, fully stir at 30°C for osmotic dehydration, reach equilibrium (stir for 70min) and put on power Further processing in an ultrasonic field of 250W and a frequency of 20kHz, the ultrasonic action time is 10, 20, 30, 40, 50, 60, 70, 80min, the results are as follows figure 1 . The ultrasonic transducer used is probe type.

[0014] Comparative experiment one:

[0015] Natural osmotic dehydration: Put 10g of peeled fresh carrot slices with a size of 1cm×1cm×1cm into 100g of 30% sucrose solution, fully stir at 30°C for osmotic dehydration, and the stirring time is 10, 20, 30 , 40, 50, 60, 70, 80min, the results are as follows figure 1 . Experimental results show that: applying the method provided by the invention, the osmotic dehydration rate of carrots exceeds the equilibrium state under natural conditions, and increases with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com