Binder-free lithium ion battery negative electrode material and preparation method therefor

A technology of lithium ion battery and negative electrode material, applied in the field of electrochemical power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

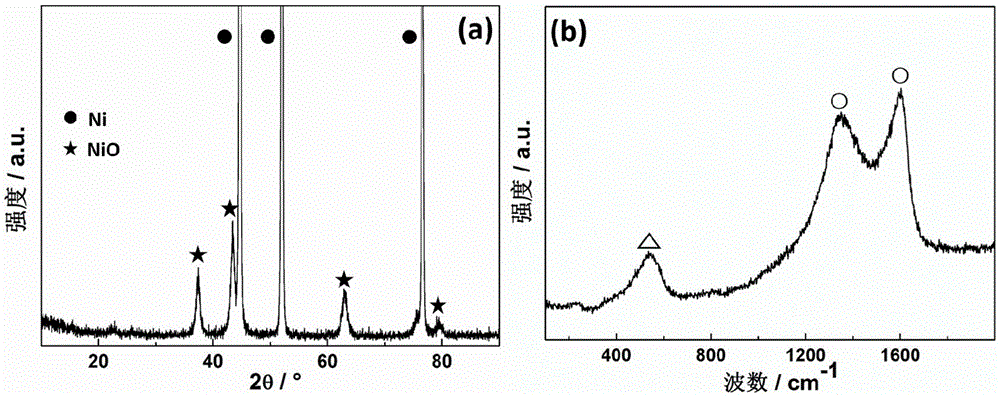

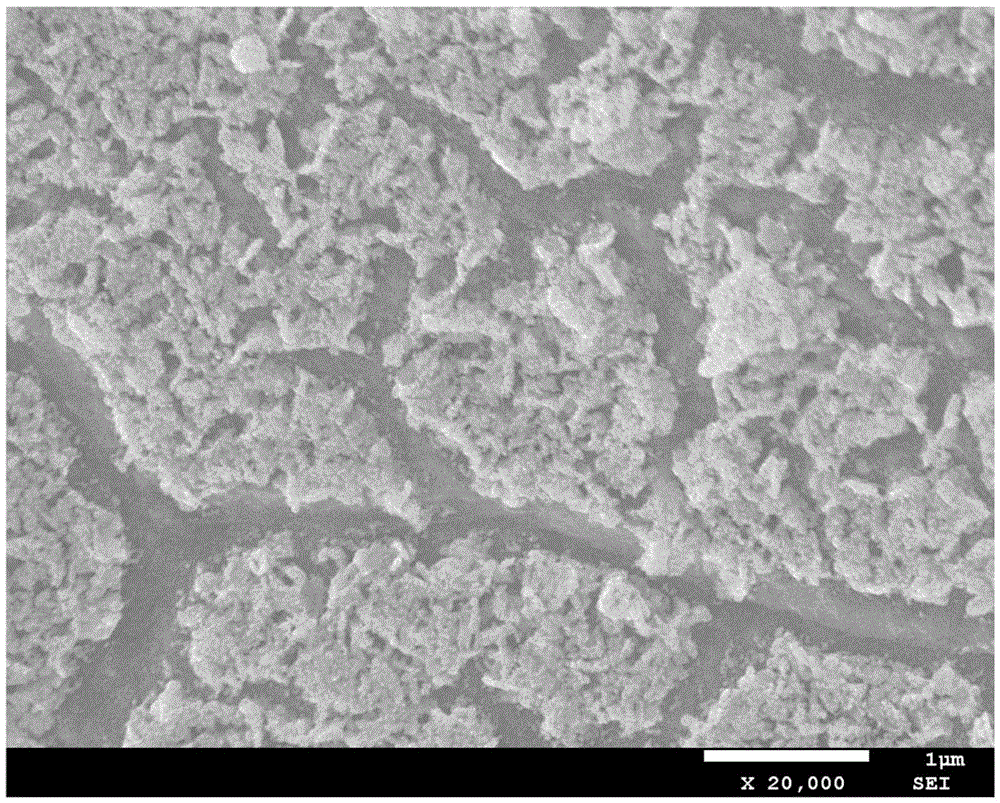

[0017] Take a certain amount of deionized water and hydrogen peroxide, mix them evenly, stir them well, transfer the evenly stirred solution to the liner of the hydrothermal reaction kettle, put a few pieces of foamed nickel into it, and react it at 120°C for 24 hours, naturally After cooling, the nickel foam was taken out and cleaned with deionized water. Put the cleaned nickel foam into a citric acid solution with a concentration of 0.002g / ml, let it stand for 5-10 hours, take it out and dry it in an oven at 70°C. Then the dried nickel foam was placed in a tube furnace under N 2 The NiO / C-Ni composite structure was obtained after sintering at 350°C for 5h in the atmosphere and cooling naturally. The prepared samples were analyzed by XRD and Raman, figure 1 (a) The diffraction peaks of the XRD pattern in (a) correspond to NiO (XRD card JCPDS, No.47-1049) and Ni (04-0850); figure 1 (b) In the Raman spectrum, the Raman peaks correspond to NiO(○) and C(△). XRD and Raman re...

Embodiment 2

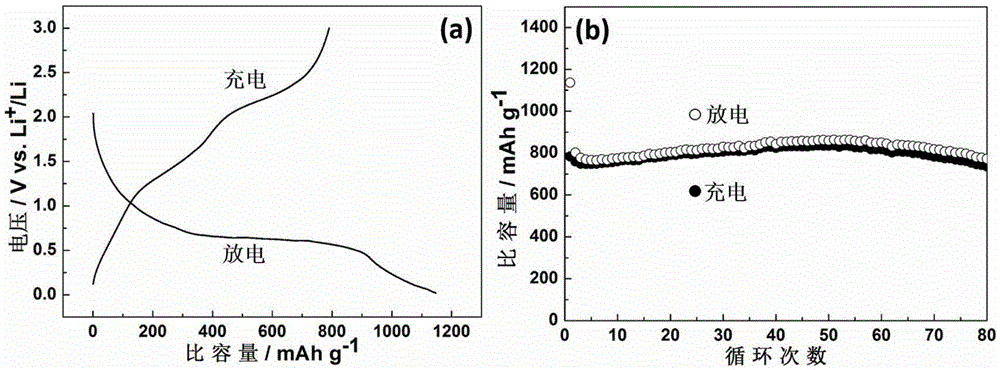

[0019] Take a certain amount of deionized water and hydrogen peroxide, mix them evenly, stir them well, transfer the evenly stirred solution to the liner of the hydrothermal reaction kettle, put a few pieces of foamed nickel into it, and react it at 120°C for 24 hours, naturally After cooling, the nickel foam was taken out and cleaned with deionized water. Put the cleaned nickel foam into the glucose solution with a concentration of 0.002g / ml, let it stand for 5~10h, take it out and place it in an oven at 70°C for drying. Then the dried nickel foam was placed in a tube furnace under N 2 The NiO / C-Ni composite structure was obtained after sintering at 350°C for 5h in the atmosphere and cooling naturally. With the prepared NiO / C-Ni as the negative electrode, a button battery was prepared according to the steps in Example 1 and its electrochemical performance was analyzed. Such as Figure 4 As shown, the first charge and discharge capacities of the NiO / C-Ni negative electrode ...

Embodiment 3

[0021] Take a certain amount of deionized water and hydrogen peroxide, mix them evenly, stir them well, transfer the evenly stirred solution to the liner of the hydrothermal reaction kettle, put a few pieces of foamed nickel into it, and react it at 120°C for 24 hours, naturally After cooling, the nickel foam was taken out and cleaned with deionized water. Put the cleaned nickel foam into a sucrose solution with a concentration of 0.002g / ml, let it stand for 5-10 hours, take it out and dry it in an oven at 70°C. Then the dried nickel foam was placed in a tube furnace under N 2 The NiO / C-Ni composite structure was obtained after sintering at 400°C for 5h in the atmosphere and cooling naturally. With the prepared NiO / C-Ni as the negative electrode, a button battery was prepared according to the steps in Example 1 and its electrochemical performance was analyzed. Such as Figure 5 As shown, the NiO / C-Ni prepared in Example 3 is used as the lithium ion battery negative electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com