Manufacturing method of biaxial MEMS (micro-electro-mechanical system) gyroscope

A manufacturing method and gyroscope technology, which are applied in the direction of manufacturing tools, manufacturing microstructure devices, and photolithography on patterned surfaces, etc., can solve the problems of no breakthrough technology and achieve low manufacturing cost, high performance, and small area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

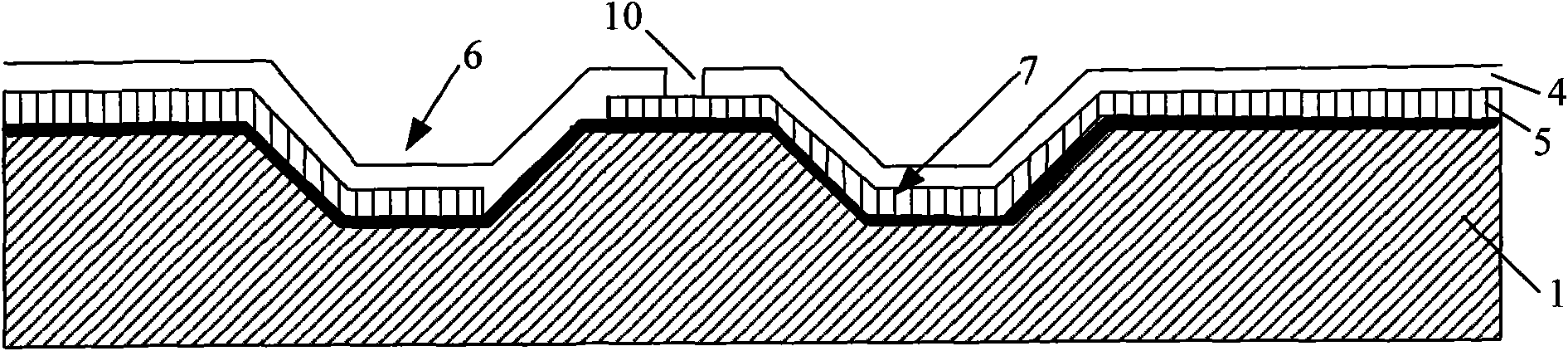

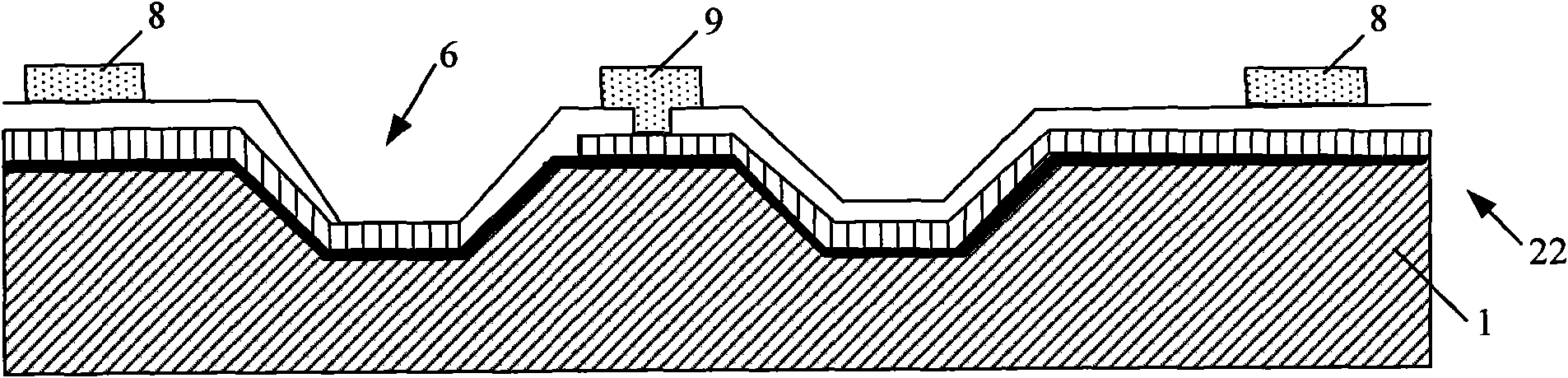

[0032] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0033] The manufacturing method of the biaxial MEMS gyroscope involved in the present invention is to process the bottom wafer, the top wafer and the MEMS wafer respectively, and finally bond the wafers together to form a biaxial MEMS gyroscope with airtight packaging instrument. Wherein, the dual-axis MEMS gyroscope includes an XY dual-axis gyroscope, an XZ dual-axis gyroscope or a YZ dual-axis gyroscope. The dual-axis MEMS gyroscope is a MEMS inertial sensor, and its manufacturing method specifically includes the following steps:

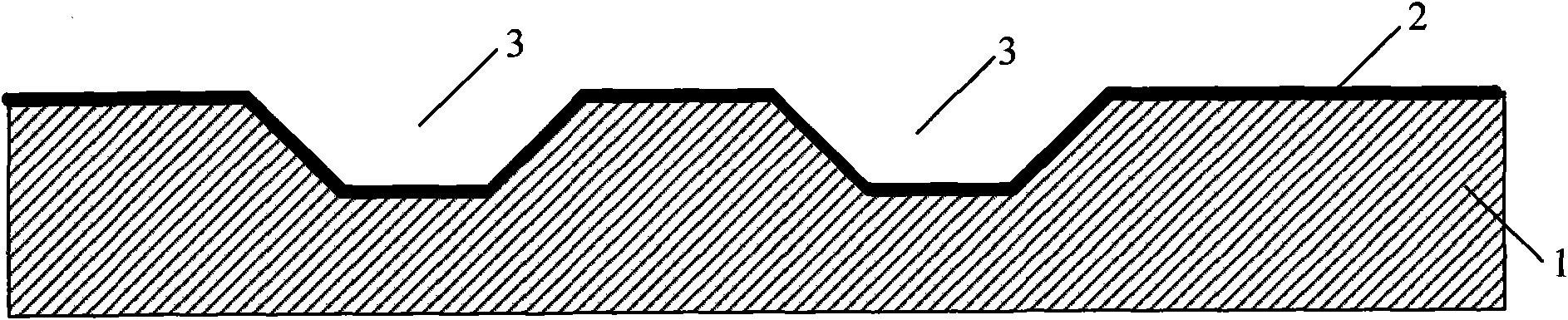

[0034] A1, such as figure 1 As shown, the step of forming the bottom cavity on the bottom wafer: provide a bottom wafer 1, and the material of the bottom wafer can be a silicon wafer or a glass wafer. Silicon nitride is deposited on the bottom wafer 1 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com